advantage of sag mill

SAG Mill Official Feed The Beast Wiki

The SAG Mill is a machine added by Ender IO. It uses Redstone Flux (RF) to grind (or mill) items into their crushed variants, like Ores into Dusts . The SAG Mill has four output slots; recipes can have 14 different outputs, with different chances of obtaining those outputs....

Ball mill preventive maintenance, SAG mill, AG mill ...

Ball mill preventive maintenance (PM) It is a frequency work to maintain and repair ball mills, AG mills and SAG mills. The maintenance work influences the rotational speed and service life of ball mills....

Optimisation of the Cadia Hill SAG Mill Circuit PDF Free ...

SAG MILL FEED SIZE DISTRIBUTION SAG mill feed size distribution was recognised as being critical to the performance of the SAG mill circuit. The Split on line image analysis system was installed in the Cadia Hill SAG mill circuit in June 1999 to confirm observations made since start up....

Rubber End Plate for ball mill, AG mill, SAG mill

In Australia, China, Brazil, etc, rubber trommels used widely in ball mills and SAG mills. Rubber and alloy composite liners applied in mines by Naipu clients in China, Australia, Brazil, Pakistan etc. Results of rubber liners and metal liners applied on SAG mill ....

advantage of sag mill

Visitors to the time warp that is the Ozarks can still find a glimpse of that world. Our selfguided tour of the past begins at Old Dawt Mill, on a back road a. Get More Info....

Autogenous Grinding Information Mine

Another requirement is that the finer sizes should break easily and should be removed from the mill, otherwise, there will be a critical size buildup. Autogenous grinding has two advantages, (1) it reduces metal wear and (2) eliminates secondary and tertiary crushing stages....

SAG Mill Control: It Shouldnt be that Hard

SAG mill control fundamentally means managing the load in the mill by adjusting the feed rate of ore to the mill and/or manipulating the rotational speed of the mill. The best way to measure load is to mount the mill on load cells....

improving energy efficiency in sag mills

Optimizing your SAG mill operation International Mining. Mar 21, 2007 the energy efficiency of a plant often rests largely on the SAG mill at relatively higher mill speeds and/or with increasing slurry viscosity....

Polycorp Minings Combination Lining

Mining › AG/SAG Mill Liners › Combination Lining. Combination Lining. Combination linings combine the advantages of steel lifters with moulded wear resistant rubber plates. Combination liners have been used for many years in tough applications in up to 32' AG Mills, SAG Mills, or ....

Ring gear drives huge grinding mill | Machine Design

Basically, a SAG mill is a rotating cylindrical container that relies primarily on the tumbling action of chunks of ore to grind each other down to the size of coarse gravel....

Turbo Pulp Lifter (TPLTM) An Efficient Discharger to ...

pump capacity, the pulp lifter design affects the discharge capacity (or mill throughput) of the SAG/AG grinding mills. The general arrangement of AG/SAG mills discharge system is shown in Figure 1. BREAKAGE DISCHARGE Figure 1: Schematic of a typical sag mill operation....

Using Fuzzy Control to Optimize SAG Mill Production

Sag Mill Example To illustrate the power of fuzzy logic we will next look at its application in controlling a typical sag mill circuit as is shown in Figure 2. Figure 2. Typical Sag Mill Configuration as Defined in KnowledgeScape. An example of controlling SAG mill speed will ....

Optimizing your SAG mill operation International Mining

Optimizing your SAG mill operation. The mill discharge from these mills consists of slurry, which goes to the ball mills for further grinding, and coarse pebbles/rocks, which are crushed and sent back to the mill. To maximize the capacity of these circuits, the general practice is to use grates with pebble ports (reaching 100 mm)......

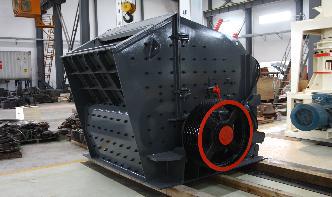

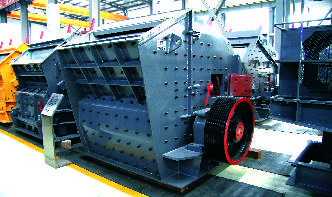

Size Reduction Visual Encyclopedia of Chemical Engineering

Size reduction in impact crushers occurs through particle concussion by rigid forces. The hammer crusher, also called the hammer mill, is an example of an impact crusher. In hammer crushers, hammers swing freely on a disc mounted on the main shaft within the device ....

Application Note SAG Mill Control

SAG mill control is essentially the stabilisation of mill load (and/or power) and density which can be implemented successfully and very costeffectively on most modern PLC or DCS platforms. The application of advanced regulatory control is a MIPAC speciality which we have applied productively in SAG milling and other mineral beneficiation processes....

Open Circuit Configuration IsaMill™ Advantages | Isamill

The type of media used in the IsaMill™ ranges from effectively 'free' media source including smelter slag and coarse SAG Mill product, to low cost locally available sands ....

Throughput Optimisation in Milling circuits | Process IQ

Sag Mill Discharge. This strategy will ensure significant increases in throughput, typically anywhere from 5% to 16% has been observed. Each milling circuit is unique, and as such the goals and most optimal control strategy might differ for individual cases. Process IQ is an expert in implementing control systems for SAG and Ball milling circuits,......

Roll Mill Advantage And Disadvantage Of Ball Mill ...

Roll Mill Advantage And Disadvantage Of Ball Mill advantages and disadvantages of rolling mill – Grinding . tripple roll mill advantages disadvantages . advantages and disadvantages of ball mill ....

Improving energy efficiency in comminution |

In this case, an AG or SAG mill may be appropriate. For smaller throughput scenarios, a threestage crushing plus rod mill plus Vertimill may make the most sense....

mining ore structure of sag mill Mineral Processing EPC

Iso Ag Mill Or Sag Mill For Sale / Semiautogenous . the most important feature of AG mill or SAG mill is to feed raw ore from the stope or after crushing the ore to the mill directly. Typically certain mineral grain size....

Optimization and Control of a Primary SAG Mill Using Real ...

Optimization and Control of a Primary SAG Mill Using Realtime Grind Measurement Steyn*, K Keet**, W Breytenbach*** ... the primary mill product in an attempt to control and possibly reduce flotation feed size variability. ... The WvalC SAG milling operation applies a similar control schema but with changes to the fuzzylogic...

Automated SAG Mill Speed Control Using Oncontact ...

Operational Trends Benefits • New Information available to the operator expert system: (3) fill level signals, Should/Toe Polar Plot LDL Signal (autospeed control). • Available as 420 mA signals and as digital variables via standard Modbus. Slide 7 Polar Plot energy plotted increasing towards the center of the graph. Mill rotating clockwise....

FL SAGwise™ to revolutionise mill liner protection ...

FL has just launched a new SAG mill liner protection solution called SAGwise™ total process control, with an estimate of less than six months ROI. ... International Mining Team Publishing Ltd 2 Claridge Court, Lower Kings Road Berkhamsted, Hertfordshire England HP4 2AF, UK. Tel: +44 (0) 1442 870 829 Fax: +44 (0) 1442 870 617...