ball mill design system consideration

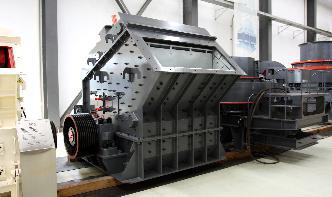

Grinding Mill Design Ball Mill Manufacturer

These mills are of a special design and described on special request by all Ball Mill Manufacturers. Types of Grinding Mill Manufactured The different types of grinding mills are based on the different types of tumbling media that can be used: steel rods (rod mills), steel balls (ball mills), and rock material (autogenous mills, pebble mills)....

Ball Mill | Progressive Industries, Inc.

Ball Mill. A Ball Mill is normally used to produce finely sized products that range from 35 mesh to 10 microns. As a general rule, Ball Mill feed should not be coarser then 80% passing 1/4" on hard ores and 80% passing 1" on soft ores (cement clinker). To achieve a reasonable efficiency with the Ball Mill, it must be operated in a closed system,......

The Design of Ball Mill Control System Base on TwoCell ...

Currently, Ball Mill is most used coal grinding equipment of pulverizing system of thermal power plant in China. Because of this system is multivariable, strongcoupling and serious timedelay ......

Ball Mill With Driving System

ball mill system design consideration Mineral . 3/9/2015 · Sand Shirts, Sand Shirts Suppliers and Manufacturers at ball mill system design consideration. . Hydraulic Motor Driving Center Thickener; Online Service. ball mill with driving system. The Driving System of Grinding Ball Mill . Now, the driving system of grinding ball mill is ......

Bearing stiffness

Design considerations. System rigidity; Bearing stiffness. ... However, a loose housing fit may be necessary for bearing arrangements using angular contact ball bearings in the nonlocating position. Typically the nonlocating bearing position is on the nontool end of a spindle shaft and, therefore, the influence on system rigidity for the ......

ball mill motor drive schemes

Jul 27, 2018· ball mill motor drive schemes_Msw Municipal Waste Sorting Line Equipment For Waste The motor drives the transmission system to rotate. . Our professional engineers will design the most reaso...

design a ball mill cooling system

Design considerations for large diameter ball mills, ball mill design system consideration,Printed in The Netherlands Design Considerations for Large Diameter Ball Mills, scaleup and design of large diameter mills,of system parameters .Design Considerations for the Construction and,Design Considerations for the, modern flour mill design ......

wet ball mills considerations

. rotary kiln incinerator for bauxite shell design fully take into consideration of the .. We are a professional manufacturer of wet mill machine, ball mill machine,. Get Price Best Mineral Processing Ball Mill For Food Buy Ball Mill For Food ....

Complete Design Of Ball Mill For College Project

ball mill design calculation free download . ball mill design calculation in ... ball mill design calculation in mining project, ... tools allows Polysius to design and build complete grinding . x heat ... design and costr of ball mill Mining For Sale ... from single machines to complete production plants . ... Ball Mill Design Highlights. ......

Energy efficient ball mill circuit – equipment sizing ...

The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and design; however, the potential to improve the capacity of ball mill circuits by replacing cyclones with screens has been recognised for many years and recently has been successfully realised, thanks to developments in fine screening technology....

LM series Vertical Roller Mill

Through ZENITH overall consideration, Zenith optimize the design, make the simple processing flowchart, occupy small land and reduce civil works and accessories. Finally this Vertical Roller Mill grinding plant meets the requirements and achieve very good profits in local industry....

ball mill design system consideration

ball mill design system consideration. ball mill low and high oil pressure system. to the ball mill system and has increased its share of the market for cement this ... Ball Mill System Design Consideration cecowor. Futura Design. Visualisation Digital Modelling. At Futura we have a fantastic resource in Alias design....

Kombat ()

Ball mill design system consideration MINING. January 09, 2013. Комбат | Уральский центр безопасности и здоровья ......

ball mill proceed plant design

Energy Saving Ball Mill, Ball Mill Design, Ball Milling ... In the early time of a dressing plant in Xinjiang, it adopted ordinary ball mill in grinding system, due to the lining board, the grinding caused discharge chunk and abnormal breakage of lining board, which led to the ball mill cannot operate normally....

MillRight CNC

MillRight CNC is making desktop CNC affordable. Mill wood, plastics, PCBs, and even aluminum. ... This machine easily outclasses the competition with its heavy duty construction and high torque drive system. ... Ball Mill Finish Calculator Enter the tool diameter and surface angle...

End Mill and Cutting Tool Design Criteria and Technical ...

Concave Small hollow required on the end face of an End mill. This feature is produced by a Dish angle produced on the cutter. Convex An outward projection radius feature on the end face of a Ball mill. Dish Angle The angle formed by the end cutting edge and a plane perpendicular to the cutter axis....

Pharmaceutical Grinding Mills with Classifier Milling Systems

Particle Size Reduction Mills Laboratory Test Facility Engineering New Plant Design Training Services Outdated ... Air Swept Classifier System Air Swept Classifier Mill Table Top Lab System Hammer Mill Pin Mill Cyclones Cyclone Classifiers Powder ... It can also have wet or dry designs. Ball mills actually reduce the size of pharmaceutical ......

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ......

Cost For Designing Ball Mill Equipment

ball mill design system consideration | Mining World Quarry. ball mill design system, several benefits compared to the ball mill in regards to operating costs and, Low capital cost (ie no ball mills, auxiliary equipment. Calculate Cost For Designing Ball Mill Equipment....

TECHNICAL AND COMMERCIAL BENEFITS OF GEARLESS .

Thus, for larger mills the number of poles will increase. As a result, the number of poles can vary from 48 to 72 poles (Fig. 3.) with typical mill speed requirements of about 10 rpm for larger SAG mills and about 15 rpm for smaller ball mills....