ball mill process of operation

High energy ball milling process for nanomaterial synthesis

The alloying process can be carried out using different apparatus, namely, attritor, planetary mill or a horizontal ball mill. However, the principles of these operations are same for all the techniques....

Emax High Energy Ball Mill Retsch

Unlike other high energy ball mills, the E max is capable of continuous grinding operation without interruptions for cooling down. This dramatically reduces the grinding time. The high energy input in combination with the unique cooling system provides perfect conditions for effective mechanical alloying or grinding down to the nanometer range....

The Operation Process and Maintenance Tips of Ball Mill

The following I will describe the operation process and maintenance tips: If you want a high operation of the ball mill and good grinding effect, you must be in strict compliance with the operating and maintenance procedures....

Ball Mill Loading Wet Milling Paul O. Abbe

Ball Mill Loading (wet milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product. Charging a Wet Mill – The general operation of a grinding mill is to have the product impacted between the balls as ......

wet ball mill operations references

Ball Mill Design/Power Calculation 911 Metallurgist. Apr 8, 2018 ... The basic parameters used in ball mill design (power calculations), rod mill or ... Process Machinery Reference Manual I will also provide 2 Ball Mill ... A wet grinding ball mill in closed circuit is to be fed 100 TPH of a......

operation of ball mill laboratory 2 medical

High energy ball milling process for nanomaterial synthesis operation of ball mill laboratory, medical,It is a ball milling process where a powder mixture placed in Read More. operation of ....

Essay about Ball Mill Design and operation 250 Words

...In the operation process of ball mill, steel ball is an important factor to affect the output of ball mill. Many casting ball users only add casting steel balls according to their experience. This often causes unnecessary loss....

manufacturing process in grinding ball mill operation in gold

Mar 28, 2017· ball mill process operation Mineral Processing EPC. Feb 18, ;32;Professional Design Ball Mill,Ball Grinding Mill,Ball Mill For . Ball mill is the key equipment for grinding after the crushing process, which is widely . Training and all around technical guidance for operation....

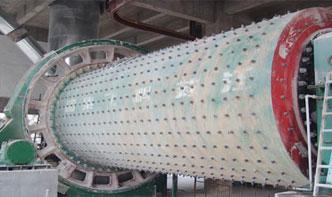

Commissioning process of ball mill Essay 529 Words

Ball mill is suitable for grinding all kinds of ores and other materials, which is widely used in mineral dressing, building materials,chemical and other industries, Ball mill can be divided into dry type ball mill and wet type ball mill....

ball mill process control

Today, the largest ball mill in operation is m diameter and m long with a . a number of variables to control and consider when using ball/pebble mills:. Get Price Throughput Optimisation in ....

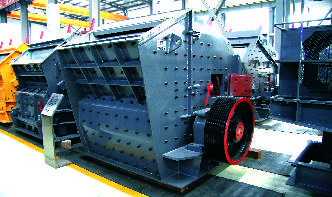

Ball Mill Operation | Crusher Mills, Cone Crusher, Jaw ...

optimization of a ball mill operation, ball mill operate methods. optimization of a ball mill operation through implementation of advanced control strategy in the feed distribution from a pressurized tank....

how to solve the problem in the ball mill operation process

High energy ball milling process for nanomaterial synthesis. It is a ball milling process where a powder mixture placed in the ball mill is subjected However, the principles of these operations are same for all the techniques such as O2, N2 in rare gases) can be problems for highenergy ball milling . More...

Laboratory ball mills Union Process

Process mode (wet, dry, circulation, batch, continuous) Scaleup capability; Ease of operation; Repeatability; Flexibility; Ease of taking samples; Ease of making formulation adjustments; Number of options; Low maintenance; In many instances, the right choice is an Attritor (sometimes referred to as a stirred ball mill)....

operation process of ball mill

operation process of ball mill. Wet FGD System Overview and Operation. Wet FGD System Overview and Operation Ray Gansley WPCA Wet FGD Seminar Power Gen International December 1, 2008. Live Chat. High Energy Ball Milling amp; How It Works Union Process....

operation of ball mill has believed

operation of ball mill has believed Factory Price Cip Gold Processing Plant,5 Tons Small Scale Gold . Jul 13, 2017 . vibrating feeder, jaw crusher, cone crusher, circular vibrating screen, ball mill, spiral classifier or hydryocyclone, jiggers, shaking tables, centrifugal ....

principle operation of ball millr equipment

A ball mill is grinder equipment used in the pharmacy to reduce the particle size of ... Ball mills give a controlled final grind and produce flotation feed of a uniform size. ... Today, the largest ball mill in operation is m diameter and m long ..... 8000, but the same approach can, in principle, be used for other ball mills....

Factors Affecting the Efficiency of Ball Mill Essay 439 ...

Ball mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics, and ball mill also can be used for the dry and wet grinding for all kinds of ores and other ......

ball mill operation and maintenance Mineral Processing EPC

High Capacity Dry Type Grinding Ball Mill Machine For Sale Buy . Features of Dry Type Grinding Ball Mill Machine. (1). Ball mill/Ball Mill machine/Grinding Ball Mill is easy maintenance and operation;. (2). Big grinding ratio....

the operation of ball mill

the operation of ball mill Changsha Yonglekang Equipment Planetary ball mill . Changsha Yonglekang Equipment, Experts in Manufacturing and Exporting Planetary ball mill machine, laboratory rotary agitator and 2906 more ... Mobile Ball Mill can process materials on site instead of transporting materials to the operation area, which reduces the ......

Overflow Ball Mill, Ball Milling Method, Principle of Ball ...

In the process of Tungsten concentrates original production, the owner adopted grid type ball mill method in two stage grinding process to achieve great capacity. After a period, the client found the production didn't reach the standard, and the equipment had a serious consumption, so the client adopted Xinhai wet overflow ball mill....

ball mill operation process mining russian

ball mill operation process mining russian; ball mill operation process mining russian. ball mill operation process mining russian. ... When the operation of ball mill is normal, the friction between steel ball and... Chat Online. Dressing Ilmenite Niobite Limonite Siderite Pyrite Magnetite....

Lead: Battery Manufacturing eTool Oxide and Grid ...

Lead oxide, which is used to create the paste used on the battery plates, is either produced by the Ball Mill Process or the BartonLike Process. It may also be purchased from an oxide producer (see receiving). The major source of lead exposure in the oxide production process comes from leaking equipment and system upsets....