ball ratio in milling process

Effect of BallPowder Ratio in the HighEnergy Milling of ...

The effects of milling time and impact force, defined as the balltopowder weight ratio (BPR), on the elemental diffusion during synthesis of nanostructured Fe50at.%Cu alloy via MA process were evaluated in the current work....

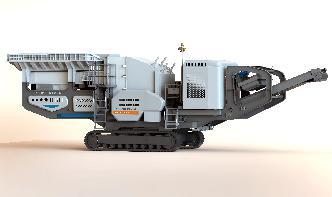

mining high grinding ratio ball mill machinery Mineral ...

Ball Mill, Ball Mill Suppliers and Manufacturers at mining high grinding ratio ball mill machinery. Ball Mill, Wholesale Various High Quality Ball Mill Products from Global Ball Mill Suppliers and Ball Mill . Mining Grinding Ball Mill for Ore/Ball Mill Machine....

SYNTHESIS OF NANO PARTICLES BALL MILLING METHOD

BALL MILLING Ball milling is a method of production of nano materials. This process is used in producing metallic and ceramic nano materials. These mills are equipped with grinding media composed of wolfram carbide or steel....

Ball Seat Milling using Electric Wireline ICoTA Canada

Ball Seat Milling using Electric Wireline Jeremy Ray . Canadian Sales Manager . ... • Adjustable gear ratio for milling purpose . Compensator Hydraulic Section Electric Motor Electronic Section ... • Debris appeared to not be of concern in milling process • Milling "untouched" ball seats is preferred...

Crystallinity and surface state of cellulose in wet ball ...

We report the effect of wet ballmilling process under mild neutral salt conditions on the alteration of crystallinity and surface state of microcrystalline cellulose (MC). The ballmilling experiments were performed when the MC was immersed in H 2 O, NaCl aqueous solution, and KCl aqueous solution....

Glucose by Ball Milling

ratios were studied to examine its influence on the ball milling process. Ten ZrO 2 balls were used (ca. 20 g) and different sample masses consisting of Ba(OH) 2 and glucose with a mass ratio of 3:1...

Ball Milling Process, Ball Milling Process Suppliers and ...

offers 2,596 ball milling process products. About 12% of these are wood router, 4% are machining, and 1% are mixing equipment. A wide variety of ball milling process options are available to you, such as free samples, paid samples. There are 2,520 ball milling process suppliers, mainly located in ....

ball milling black powder

BallMilling Black Powder The one, critical machine which makes this method of manufacturing black powder possible is the ball mill. The Quick Easy Black Powder Ball Mill project presents an overview of a good, small, economical ball mill and provides important directions and safety information for ....

ball milling process of zno

Energy Saving Iron Ore Coarse Grinding Ball Mill,China Gold Ore Crusher Milling Mining . through the discharging board thus the grinding process is finished. .. cooler, coal mill ) and magnesium production line ( zinc oxide production line,....

Research Article Process Parameters Optimization of Silica ...

ere are a lot of parameters used in ball milling process. However, the parameters that have been tested most for ... Ball mill is used for the purpose of grinding all kind of mines and materials [, ]. roughout the years, it has ... Ball to powder weight ratio : Volume of milling jar .L Rotation speed rpm 7. Summary...

Ball Milling University of Massachusetts Boston

A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 . ... process Tip of iceberg . Reference...

ball and material ratio of ball mill ratio

China Wet Ball Mill Suppliers Henan Yuhong Produce Gold Ball Mill Liners,Ball Mill For Sale, Find When the L/D ratio is 2 to 1 or greater, we refer to the mill as a Tube mill. The grate serves to retain balls, tramp, and coarse material....

OPTIMIZATION OF MACHINING PARAMETERS IN BALLEND .

SignaltoNoise (S/N) ratio and Analysis of Variance (ANOVA) are employed to analyze the effect of ballend milling parameters on the orthogonal cutting forces in other words to find optimal levels of the process parameters. The study shows that the Taguchi method is suitable to solve the stated problem with minimum number of trials. Keywords ......

high energy ball milling process for preparation of ...

high energy ball milling process for preparation of nanomaterial ball milling process to prepare babi2nb2o9 educationcare. ... The powder to ball mass ratio was 150 with a powder mass of 100 g. Get Price Materials and Manufacturing Processes tandfonline....

ball milling machine process pdf China LMZG Machinery

ball ratio in milling process – Grinding Mill China Traduire cette page ball ratio in milling process [ 9498 Ratings ] The Gulin product line, consisting of ....

Process Parameters Optimization of Silica Sand ...

Orthogonal array and signaltonoise ratio are applied to study performance characteristics of machining parameters which are the ball to powder weight ratio, volume of milling jar, and rotation speed. Results obtained from signaltonoise ratio analysis showed that ball to powder weight ratio is the most influential parameter....

ball milling speed

Dec 3, 2014 The study of milling time effect on BN peeling was based on 1 mm steel balls with a balltopowder weight ratio of 10:1 at a milling speed of 800 ... Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs....