blasted copper ore size

Blast Furnace For The Extraction Of Copper YouTube

May 03, 2010· Blast Furnace For The Extraction Of Copper Blast furnace is a the furnace which is used in Metallurgical process such as Smelting to reduce industrial metals from ....

Copper mining in Michigan Wikipedia

Copper mining in Michigan. In the 1850s, ... with the ore blasted out, hoisted to the surface, and sent to stamp mills located at a different site. Amygdaloid and conglomerate mining turned out to be much more productive and profitable than fissure mining, and the majority of highly successful mines were on amygdaloid or conglomerate lodes. ......

Cost Models of Theoretical Mining Operations | CostMine

This mine is an open pit mine producing 5,000 tonnes ore and 5,000 tonnes waste per day. Rock characteristics for both ore and waste are typical of those of granite or porphyritic material. Operating conditions, wage scales, and unit prices are typical for western mining operations. All costs listed are in ....

Home Kleen Blast

Van Air FD250 Blast Pak Air Dryer 10, 9, Sale! Add to cart Show Details. 1 Cuft Classic Blast Machines 1, Add to cart Show Details. Black Max Fans and Equipment From: 1, Select options. Tacoma, Washington. 1448 St. Paul Avenue....

Chemistry Tutorial : Copper Smelting

A typical copper ore contains between % and % copper. A high grade ore produces a high yield of metal. A low grade order produces a low yield of metal. Copper can be extracted from sulfide ores (usually higher grade ores) by direct smelting....

Bob's Rock Shop: Bingham Canyon Copper

By 1980, the huge Bingham Canyon Mine had 2,500 miners who drilled and blasted 370,000 tons of ore and overburden every day. An additional 5,200 employees worked in haulage, concentrating, smelting and refining to produce 300,000 tons of pure copper each year....

The Copper Basin Georgia Mineral Society

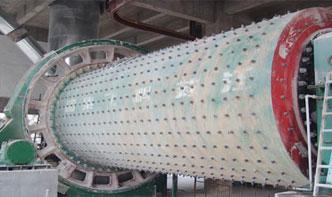

The ore was blasted and dumped down a shaft for primary crushing. At the Cherokee Mine, the primary crusher was below sea level. ... the ore went to secondary crushers where it was crushed to 1/2 inch size. It then went to a ballmill and was ground to a powder. ... The mining of the Copper Basin ores was a magnet for people to come into the ......

3. Processing of Copper Ore

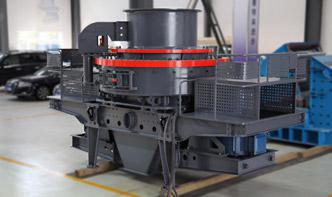

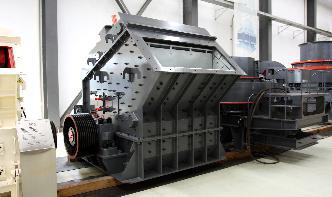

The process varies slightly depending on the type of ore that is being mined. Sulfide ores are first put through a jaw or gyratory crusher to reduce the rocks to about 7 8 inches. This material is then fed to a secondary grinder that further reduces the size to about 1 2 inches....

The recovery of oxide copper minerals from a complex ...

Results. According to the copper deportment in the ore; % of the copper reported as chrysocolla, % as chalcopyrite, % as cuprite and % as malachite/azurite. The focus of the study was therefore on chalcopyrite and chrysocolla because they were the two most abundant copper minerals....

ball mill size of copper ore

Ore Benefication plant factory steel ball mill for grinding copper ore and coal mill size hot in America and Mexico. US Set. 1 Set Min. Order. Get Price Copper Ore In Zambia. Gold/Copper ore grinding ball mill popular in Zambia. Add to Compare 2018 YUHONG copper ore grining ball mill mining machinery Hot Sale In Zambia. Get Price Copper Ore Chile. Dextrorotation transmission MQS ....

MEI Blog: Challenges in copper flotation Barry A. Wills

Sep 10, 2011· The development of froth flotation had an enormous impact on copper mining, enabling chalcopyrite and other sulphides to be efficiently separated from ores of relatively low grade and fine grain size. Until 1907 practically all the copper mined in the USA was from underground vein deposits, averaging % Cu, whereas flotation allowed the mining of porphyry deposits of only % grade....

Pilot scale microwave sorting of porphyry copper ores ...

Pilot scale microwave sorting of porphyry copper ores: Part 2 – Pilot plant trials. ... For the 11 ore types and three size classes (− ... The predetermined sorting decision is implemented and the pneumatic actuators blast the lowest mass fraction (either accepts or rejects, although for the purposes of illustration rejects (or Colds ......

copper ore size reduction ball mill and screening mining equ

copper ore size reduction crushing mabmbhu. copper ore size reduction crushing. Outotec Wikipedia. Outotec Oyj is a Finnish listed technology company that was created when Outokumpu Oyj span off its technology business into a separate entity in 2006....

How is copper processed

First the copper ore from a open pit mine is blasted, loaded and transported to the primary crushers. Then the ore is crushed and screened, with the fine sulfide ore (~ mm) going to froth ......

Determination of liberation size of Akiri copper ore ...

The liberation size is 125µm sieve size having the highest recovery of copper in its elemental and oxide form, of and percent respectively. Recommendation. Base on the result of the research work, it is recommend that further investigation on the separation of the copper ore using 125µm sieve size....

Sublevel open stoping QueensMineDesignWiki

Sublevel Open Stoping originated in the early 1900's in iron ore mines in Michigan, USA. It was developed over the years from a method originally known as short hole bench and train a large scale open stoping method, it is often referred to as long hole or blast hole stoping....

What's the process of iron ore mining? Quora

Answer Wiki. Mining iron ore begins at ground level. Taconite is identified by diamond drilling core samples on a grid hundreds of feet into the earth. Taconite rock comprises about 28 percent iron; the rest is sand or silica. These samples are analyzed and categorized so that mining engineers can accurately develop a mine plan....

Blast Furnace Sizing Considerations for Incredible India

may drop by up to 5 % when comparing medium size furnaces with small furnaces and large furnaces with medium size furnaces respectively. This is illustrated in Figure 3, which plots furnace productivity and working volume for a handful of multiple blast furnace sites....

Exploring the Site of the Former Copper Mines on the Dvoor ...

Some were out to make a quick buck via stock jobbing; others were serious attempts to draw copper ore from the earth. In the end, ... muck being the term for rock blasted out of the underground and hauled to the surface. Any time you have rock that's broken up, that's the muck." ... I had a copper bearing rock about the size of your fist ......

(PDF) HPGR Comminution for Optimization of Copper Leaching

HPGR Comminution for Optimization of Copper Leaching ... a decrease in the particle size of the copper sulfide ore as exposure of copper mineral grains increased. ... grinding rolls for ......

Fortnite HOW TO FIND COPPER ORE | FARMING GUIDE ...

May 06, 2018· In this video I will be showing you how to farm Copper Ore in Fortnite Save The World. Thanks for watching! I do not own thumbnail pictures. My ....

copper ore cile mine size

Copper Ore Chile Mine Size copper ore cile mine size Rock masses of the primary copper ore at the El Teniente Mine are very competent and massive. dicted in situ block size Chile. 2CRC Mining, ... Get a Price. copper ore cile mine size ...