calculating through feed angles for centerless grinding

Improving Workpiece Roundness through Centerless Grinding ...

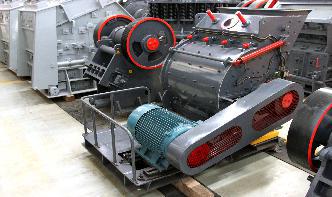

ThrouqhFeed Centerless Grindinq In throughfeed centerless grinding, the rotational axis of the regulating wheel is tilted by a throughfeed angle, 0 (Fig. l), so that workpieces can be fed across the width of the grinding wheel as they rotate....

Precision Metal Grinding Lapping Services

We have two types of throughfeed centerless grinders. One design has an open architecture that allows for high throughput speeds and fast changeovers; the other is customized to hold extraordinary submicron diameter tolerances....

Grinding and Honing | Rable Machine Inc.

Grinding is most commonly used when a material is too hard to machine efficiently or when the tolerances required are too precise for machining. Rable Machine's grinding capabilities including centerless grinding, through feed grinding, plunge form grinding, Grinding, grinding honing and surface grinding....

how centerless grinding of rollers works

how centerless grinding of rollers works: ...o find new used centerless grinders for sale. ... calculating through feed angles for centerless grinding. gold extraction from sand in india. copper mines in pakistan. global gypsum co llc oman. examine the evolution of ....

The Disadvantages of Centerless Grinding | Career Trend

Throughfeed grinding, endfeed grinding and infeed grinding are three types of centerless grinding and have certain disadvantages to the production process. ... Other disadvantages for centerless grinders include that if the object is perpendicular, such as having a right angle, the grinder has difficulties working on and improving the object ......

Centerless Grinding Manufacturing Review Engineers Edge

Centerless grinding manufacturing is a finish machining process for cylindrical parts. The cylindrical part is located and supported between two opposed grinding wheels and feed at a controlled speed. There are several techniques of centerless grinding....

ThruFeed Grinding Precision Grinding

InFeed Grinding. Infeed grinding is ideal for headed, flanged or multiplediameter parts that require two or more diameters to be ground. Also, single, multistep, angles, tapers and radii benefit from the ....

Centerless Grinding Tolerances TriangleGrinding

Centerless Grinding Tolerances. We utilize our 50+ years in business to leverage industry leading standards and centerless grinding tolerances. Call us today and we can discuss your tolerance and capacity needs. Minimum infeed diameter: .020 inch (.5mm)...

Throughfeed One Machine Grinding Calculations

Before designing a grinding cycle and machine setup, the software needs to know the Part information and Machine information. Most information of the part should be shown on a typical drawing. Each part can be added to a database and appears in a table so that it can be used for future use....

traduccioacuten traduccioacuten pepper mill espaol

calculating through feed angles for centerless grinding Centerless Grinder IssuePractical Machinist. Anyways, I own a small centerless grinding job shop in SouthernIt seems that no matter how much I close this angle, the parts still continue to grind toward the exit side of theAre you through feeding with the next part right up aginst the rear ......

calculate cycle time in surface grinding

how to calculate grinding cycle time in centerless grinding centerless grinding, static compliance is an important parameter governing . and cycle time [2]. .. ....

Fundamentals King Centerless Grinding Services

THE FUNDAMENTALS OF CENTERLESS GRINDING. Running bar stock is simply an extension of the thrufeed process. Grinding bar stock on a centerless grinder uses the same concept of setting the wheels at an increasingly small taper to remove stock, passing the bars through the wheels to produce a consistent diameter for parts as long 20 feet. Infeed –......

JHC12 Centerless Grinder: Jainnher Machine Co., Ltd.

In order to upgrade the straightness and the surface finish on throughfeed grinding of long work pieces, please adjust the angle of the dressing device (swivels ±5 degrees). The regulating wheel should be adjusted to resemble a concave barrel to increase contact length while grinding....

Faster Setup for Centerless Grinders : Plastics Technology

The machines in this series (the Jupiter 125, 250 and 500) are capable of straight (throughfeed) and angular plungecut grinding. Angular grinding is required for any part on which shoulders are ground, including workpieces recessed with different diameters....

What is Centerless Grinding?

Throughfeed centerless grinding allows the work piece to be fed rapidly into the grinding wheels and passed through to the next stage of production. The drawback of this system is that only square, rightangle cylinders can be passed through the system....

through feed centreless grinding il

CNC centerless grinding infeed grinding throughfeed ... Our years of experience, commitment to service and stateoftheart CNC centerless equipment put us at the top of our industry. We provide infeed and throughfeed grinding, as well as highvolume production services with ....

centerless grinding sides

In the centerless grinding process, the angles at which the wheels contact the part are critical to achieving the proper roundness and tolerance. Generally, the centers of the regulating and grinding wheels are set at the same height on the machine, and the center of the workpiece is situated higher. ... Centerless grinding and through feed ......

Centreless Grinding Troubleshooting Midland Abrasives

Centreless Grinding. Too great an angle on workrest blade A 3O° angle should be a good average starting angle for most work. Long blades will cause chatter unless blade angle is reduced. Also for small diameter work it will generally be necessary to reduce angle. Work support blade too thin Use a ....

Faster Setup for Centerless Grinders : Additive ...

Centerless grinding is characterized by a grinding wheel and a regulating wheel rotating in opposite directions. The workpiece is supported underneath by a blade that can be adjusted automatically for the optimum height setting on the Jupiter grinders....

Grinding and Guidewires: Manufacturing for Minimally ...

In 1966, the process of centerless grinding was used for the first time to create a simple taper into a stainless steel wire, providing a faster solution and eliminating the need for chemicals. Centerless grinding utilizes a grinding wheel and a control wheel. The control wheel rotates the work piece as the grinding wheel cuts into it....

Performing infeed type centerless grinding process on a ...

Performing infeed type centerless grinding process on a surface grinder ... the workpiece roundness can be further improved by varying the eccentric angle during grinding, and the final roundness ......

Grinding Machining – Deltronic Corp

Let us put our 40 years of experience in HighPrecision Centerless Grinding and Lapping to as fine as 10millionths tolerances, one microinch finish, to work for you. ... Infeed Plunge Radius. Throughfeed Undercut Diameters. Endfeed Angles...

Precision Grinding and Microfinishing | 3M

Centerless grinding. Creepfeed grinding. Cylindrical grinding. Gear grinding. Tool grinding. They all demand precision. And to achieve the highest precision, you need the best abrasives. 3M offers all the abrasives to take your precision grinding, finishing and microfinishing operations to the next level....

what the principle of centreless grinding

Working Principle Of Centerless Grinding Machine grinding machine working principle – Grinding Mill China. ... Precision Centreless Grinding Through Feed ... Principle: The principle of centreless grinding can be seen in the diagram below. ... The work height and the contact angles are shown in Fig. for an external centreless process ......

(PDF) A new throughfeed centerless grinding technique ...

A new throughfeed centerless grinding technique using a surface grinder Article (PDF Available) in Journal of Materials Processing Technology 211(10): · April 2011 with 590 Reads...