calculation of production of cement mill

Cement Extraction and processing |

There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned product, known as "clinker," together with some 5 percent of gypsum (to control the time of set of the cement)....

calculation of production of cement mill

cement mill calculation pdf calculation of cement ball mill capacity Jul 26, 2016 Group is a professional mining machinery cement ball mill throughput calculation Live Chat ball mill size and production throughput ball mill throughput capacitygraphite flotation processing plant>cement ball mill throughput calculation and enable production ......

Raw Mix Preparation ABB Ltd

OptimizeIT Raw Mix Preparation Raw mix preparation is the quality key control parameter upstream for stable, continuous manufacture of high quality clinker and cement. Downstream quality and up to 5% production increases or savings originate from ABB's quality assurance system OptimizeIT Raw Mix Preparation. The...

ENERGY AND EXERGY ANALYSIS OF THE KILN SYSTEM IN .

111 clinker production is supplied through top of the preheater about /sec (550C). The gas streams at outlet of the system are preheater exhaust gas (395 0C), cooler hot air (220 0C) and coal mill gas (340 0C). The gas streams at inlet of the system are primary air (53 0C) and cooler air to cool the clinker....

Velocity Calculation In Ball Mills | Crusher Mills, Cone ...

formula calculates the critical speed of a ball mill. Critical Speed Calculation Of Ball Mill – Raymond Grinding Mill. . CEMENT MILL FORMULAS MILL CRITICAL VELOCITY = 76 / (D)^1/2 MILL. Ball Mill 1. n = C (AB ....

cement mill capacity calculation solution for ore mining

raw,cement ball mill volume loading formula technobuild formula to calculate ball mill volume loading cement ball . cement mill capacity calculation formula. cement ball mill mill. >>Chat online! volume density: 400~700kg/m3,1/4 of common cement,1/3 of fireclay brick and 1/2 air b....

Production Cost Calculation Of Cement Grinding With Ball Mill

production cost calculation of cement grinding with ball mill. FLzenith ball mill for cement grinding FLzenith ball mill for cement grinding. The FLzenith ball mill is designed for grinding of clinker, favourable cost and short ......

calculation of production of cement mill

calculation of production of cement mill. Home; calculation of production of cement mill; PAMC is a highly professional Horizontal Boring Machine,Grinding Mill,Crusher also offers calculation of production of cement mill, screening attachments, drum cutters and grapples....

normal speed calculation for cement ballmill BINQ Mining

Dec 19, 2012· Cement Production Line »More detailed. ball mill rpm calculation, introduction to the mill mit massachusetts. ball mill power calculation (for cement 2 chambers) . rpm. % critical speed. lining type. average thickness, mm. kind of media, (balls=0, cylpebs=1). top size diameter ....

Calculations For Efficiency Of Cement Ball Mill

Ball Mill Efficiency Cement Calculation. ... plzzz suggest me how get calculation of cement mill operations,Calculations for mill motor power, ... calculation of grinding efficiency of ball mill in cement ....

how to improve cement mill production

increasing of production efficiency of cement mill calculation of production of cement mill, reinforced definition of reinforced definition of reinforced by the free online ... how improve cement mill ....

Variation of Feed Chemical Composition and Its Effect on ...

Portland Cement) is the most common type of cement in general use around the world because it is a basic ingredient of concrete, mortar, stucco and most nonspecialty grout....

hammelcalculation of cement sand aggregate crushing ...

Calculation Of Cement Sand Aggregate . ... Grinding Mill China. Production Line Products » Mobile Crusher concrete grade c32 40 cement sand aggregate ratio. cementaggregate ratio. ... The new dry type cement production line is a modern cement production method with the prehomogenization technology and rotary kiln calcining technology as the ....

Cement making process Great Wall Corporation

Since the raw meal grinding work takes up more than 30% labor force in the whole dry process cement production line, ... The clinker is finely ground with about 5% gypsum in another ball mill, producing cement. (The gypsum regulates the early setting characteristic of cement). The finished cement is stored in silos then carted to our wharf or ......

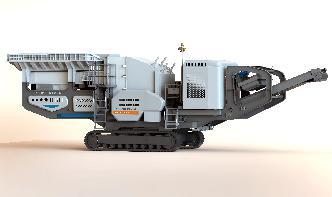

production rate of cement mill

production of cement mill cement mill cement production Cement mill Wikipedia. A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into A 10 MW cement mill, output 270 tonnes per hour....

how to calculate cement mill separator efficiency

how to calculate cement mill separator efficiencyhow to calculate cement mill separator efficiency (An EnglishChineseJapanese Dictionary of Technology MSC,。 ... CEMENT INDUSTRY Cement Mill Notebook QATAR NATIONAL CEMENT In order to calculate the approximate production of cement % efficiency of separator....

Per Ton Power Consumption Of Cement Mill Calculation

calculation of cement ball mill capacity. per ton power consumption of cement mill calculation Jaw per ton power consumption of cement mill calculation 111 It has a production capacity of 1700 tons of clinker and 4000 tons of cement. before directing to Traditionally, ball mills are used in cement...

Modern Processing Techniques to minimize cost in .

Typically, the motor of the ball mill consumes about 14 15 kWh/ ton of raw mix whereas the VRM motor uses 7 8 kWh/ ton. On an overall basis, VRM consumes about 20 % lower specific energy than conventional closed circuit ball mills and is being widely used for ....

Portland Cement Manufacturing US EPA

Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement. ... Portland cement accounts for 95 percent of the hydraulic cement production in the United States. The balance of domestic cement production is primarily masonry cement. ... ball or tube mills, thereby ......

CALCULATION OF THE POWER DRAW OF DRY .

Annual cement production is approximately billion tons and the grinding process consumes nearly 2% of the electricity produced in the whole world (Norholm, 1995). ... Calculated mill load volume with using different calculation method for Çorum cement mill Calculation Method Mill Load Volume 1st Chamber 2nd Chamber Geometric equation ......