cement grinding process in details

cement | Definition, Composition, Manufacture, History ...

Another essential raw material is gypsum, some 5 percent of which is added to the burned cement clinker during grinding to control the setting time of the cement. Portland cement also can be made in a combined process with sulfuric acid using calcium sulfate or anhydrite in place of calcium carbonate....

CEMENT PRODUCTION PROCESS SlideServe

CEMENT PRODUCTION PROCESS. ROLLER MILL. ROLLER MILL. V ertical R oller M ill (VRM) 3 Sections. Separation Grinding Drive . Vertical Roller Mill (VRM) Details. VRM Working principle. Grinding force = Roller weight + (pressure) Force. Material bed....

Cement Making Process CRH Cement

Cement Grinding General purpose cement (Portland) is composed primarily of clinker blended with gypsum to control setting time. These materials are ... Explore the cement manufacturing process below. Cement Vs. Concrete . Cement is often confused with concrete. A common misconception is cement and concrete are interchangeable terms....

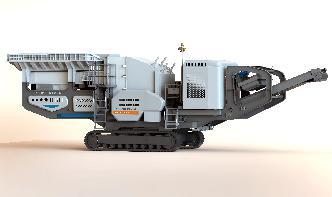

Equipment of Tons Per Year Cement Grinding Process

Cement Grinding Process manufacturer / supplier in China, offering Equipment of Tons Per Year Cement Grinding Process, *13m Center Driving Cement Mill, * (+) Raw Mill Used in Cement Production Line and so on....

Cement Fundiciones Estanda

Steel products for the grinding of raw material and cement, designed to enable the ball grinder to function optimally and to improve productivity. PreHeaters. Steel components for pipes and cyclones of preheaters of raw cement: dipping tubes, tipping valves....

Clinker Grinding Units Cement Grinding Unit Exporter ...

Exporter of Clinker Grinding Units Cement Grinding Unit offered by Megatech International Private Limited, Alwar, Rajasthan....

DETAILED ENERGY AUDIT AND CONSERVATION IN A .

The grinding process, where clinker along with other additives is ground to form different grades of cement. c. The schematic of the overall cement production flow chart is given in the Figure Overall Flow Diagram of Cement production process....

grinding process in manufacturing cement

(Grinding, raw material grinding process in cement industries,Cement grinding is a process performed. Manufacture of Portland Cement Materials and · Manufacturing of cement involves various raw materials and processes....

Cement Manufacturing Process Civil Engineering Blog

Cement Manufacturing Process. The entire operation of the plant is controlled centrally in a single control room and the plant employs minimum of manpower. The modern plants have also taken adequate care to prevent the environmental pollution and dust nuisance to its surrounding areas. The cement mills have electrostatic precipitators (ESP)......

graphite grinding machine price, cement plant

what is the price of ball mill for graphite grinding in . plant cement Cement and Grinding Equipment for Graphite Ore Process Coal Mill in Grinding Process Of China Clay grinding media consumption in cement wet . grinding media consumption in clay graphite grinding china clay washing plant process grinding mill china....

How Cement Is Made

The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process....

Manufacturing process | Home : Lafarge Cement

From the limestone quarry to the delivery of the end product, follow every step in the cement manufacturing process. ... Jump to navigation Jump to search Jump to content. Zambia. LafargeHolcim Worldwide. Contact. About us. Lafarge in Zambia ... Very fine grinding produces a fine powder, known as raw meal, which is preheated and then sent to ......

Manufacturing process | Lafarge Cement, concrete ...

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km....

grinding plant cement production process

GRINDING PROCESS. Cement plant >>Details; cement grinding optimisation CiteSeerX. Grinding occurs at the beginning and the end of the cement making process. Mill power draw prediction can be carried out using Morrell's power model for tumbling mills. (Morrell, 1998). Bond method. The established technique for There are efficiency factors for ......

Portland Cement Manufacturing US EPA

A diagram of the process, which encompasses production of both portland and masonry cement, is shown in Figure As shown in the figure, the process can be divided into the following primary components: raw materials acquisition and handling, kiln feed preparation, pyroprocessing, and finished cement grinding....

Pavement Manual: Diamond Grinding Search

Pavement Distresses that Require Diamond Grinding (DG) Pavement roughness increases dynamic loading and resulting wheel loading stresses, thus reducing pavement life. Pavement roughness can be effectively corrected by DG. DG increases macrotexture of the surface, thus improving drainage and skid resistance, and reducing the potential for hydroplaning....

Cement Grinding Aids

The cement grinding aids is additional material in liquid or solid form, admixed in small amount during the cement clinker grinding process which can significantly improve the grinding efficiency and reduce energy consumption, without compromising the performance of the cement....