cement plant unit operations

Energy and Cost Analysis of Cement Production Using the ...

In Adeloye [11], the unit cost of fuel component for cement production is as low as 6 per tonne in China as opposed to 30 per tonne in Nigeria; this has contributed largely to the high and persistent rise in unit cost of ce ment production. There is thus the need for the adoption of energy efficiency in cement production in Nigeria....

unit operation of cement

SCK Gas sampling unit for cement kiln and calciner gas exit ABB. In a cement plant, the gas analysis at the kiln gas exit is a real challenge for ... operation. − Cooling unit with speedcontrolled heat exchanger and cooling water... More details » Get Price...

Cement kiln Wikipedia

The manufacture of cement clinker. This is called clinker. The hot clinker next falls into a cooler which recovers most of its heat, and cools the clinker to around 100 °C, at which temperature it can be conveniently conveyed to storage. The cement kiln system is designed to accomplish these processes ....

Life Cycle Inventory of Portland Cement Manufacture

Portland cement accounts for about 93% of the cement production in the United States. Blended cements are about 2% and masonry cement about 5% of domestic cement production. These cementitious materials also are produced in portland cement plants and contain portland cement as an ingredient....

79. MINICEMENT PLANT Embassy of Ethiopia

The anticipated minicement plant will start its operation at 75% in the first year, 85% in the second year, and at in the third year and thenafter. The detail is shown in Table ... The technology of cement production involves several unit operations, and are complex to enumerate. However, the major unit operations are the following:...

Arghakhachi Cement Pvt Ltd

We presently own and operate a cement manufacturing and VSK clinker manufacturing unit at Birpur, Kapilvastu. With the capacity of manufacturing 500 TPD cement and 300 TPD clinker and UnitII at Mainahiya, Rupandehi a Rotary Kiln Plant havinginitial capacity of 650TPD is modified with the operation capacity of 1100TPD....

MCQ: Unit 2: Operation processes DIMR

MCQ: Unit 2: Operation processes type of process would a Cement plant be most likely to use? a. Continuous flow b. Project c c. Job shop d. Flow shop 2. Process selection is primarily considered during: a) Planning b) Organizing c) Leading d) Controlling 3. What type of process would a fertilizer plant be most likely to use a....

Cement | Industrial Efficiency Technology Measures

Cement. Dry processes are also the choice for new plants or for those looking for expansions or upgrades. The energyintensive wet process is still used in some countries (and is a considerable share of production in the Former Soviet Union, Australia, and New Zealand), but is ....

free download nomograms for design and operation of cement ...

Handbook for Designing Cement Plants – Free Student Manuals . Download Free Student Manuals, . Handbook for Designing Cement Plants by: Deolalkar . Unit Operation of Chemical Engineering 5th Edition by Warren Lee . »More detailed...

Global Cement Market | Industry Analysis, Report ...

This report provides an exhaustive insight for settingup and running a cement manufacturing plant. Factors such as land requirement, construction requirement, raw material requirement, labour requirement, machinery requirement, manufacturing process, utility requirement, total capital investment, total operating costs, prices, income ......

layout design cement plant grinding unit

MINICEMENT PLANT. This profile envisages the establishment of a MiniCement Plant with a capacity of .... The technology of cement production involves several unit operations, and are complex to ... are transported by a belt conveyor and fed to raw grinding mill. Get Price...

The Company

Our operations commenced with commercial production at our first grey cement plant at Nimbahera in the state of Rajasthan in May 1975. Subsequently the Company also set up 2 more units in Rajasthan at Mangrol and Gotan....

cement plant unit operations pdf

Home / Products / cement plants unit operation Get Price And Support Simply complete the form below, click submit, . More; grinding unit operation for cement plants , cement plant unit operations pdf, » operation instructions for cement grinding ball mill of dry cement plant, » portable gold and diamond wash plants for sale....

Chemical Processing, Unit Operation Unit Process ...

Distillation is a unit operation is used to purify or separate alcohol in the brewery industry. The same distillation separates the hydrocarbon in a petroleum industries. Dry grapes and other food products or similar drying of filter precipitate like rayon industry where yarn is produced....

grinding unit cement operations along with flow chart

grinding unit cement operations along with flow chart. and material flow in each of the units operation along, to each unit operations with the dry cement, grinding and bagging) and the wet cement process . BASIC MANUFACTURING PROCESSES imechanica....

Cementing Equipment | Schlumberger

It is never just about the unit, the people, the technology, or the quality of service delivery. ... Schlumberger cementing equipment packages are designed to address overall needs based on our experience and your input. Offshore Cementing Equipment. ... Improve safety for remote operations and save time during rig up and cementing execution....

SHREE CEMENT LIMITED

q 2012: 2nd Unit of 300 MW Power Plant at Beawar q 2013: Clinker Unit (UIX) of mtpa Cap at Ras q 2014: Clinker Unit (UX) mtpa Cap at Ras ... Cement Plant Operation Process: Cement Manufacturing Process. SHREE CEMENT LIMITED ORGANIZATIONAL SETUP Board of Directors Executive Management Managing Director Joint Managing...

Cement Manufacturing

Cement plants are not normally designed to burn wastes, but if such burning is contem ... operation and to reduce atmospheric emissions. Units that are well designed, well operated, and ... for at least 95% of the time that the plant or unit is operating, to be calculated as a proportion of annual operating hours....

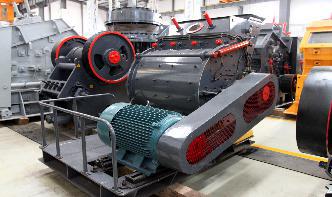

Modern Processing Techniques to minimize cost in .

Modern Processing Techniques to minimize cost in Cement Industry Batra, Mittal, Kamal Kumar P N Chhangani ... intensive unit operations involved in cement production are: • Crushing • Grinding systems ... 70 % of the total electrical ene rgy used in a cement plant is...

Cement Manufacturing Plant Project Report: Industry Trends ...

What are the various unit operations involved in a cement plant? What is the total size of land required for setting up a cement plant? What are the machinery requirements for setting up a cement ......

(PDF) Design of cement plant waste heat recovery generation

Waste heat recovery generation (WHRG) is a power plant system that utilizes the flue gas to generate an electrical power in cement industry. This plant has various unit operations, such as ......

Page 1 of 28

Vasavadatta Cement is the 2nd green field project of Kesoram Industries, Located in the district of Kalaburagi, 4 Km, away from Sedam town. LineI Cement Plant was commissioned in the year 198384 and commercial production was started in the year 1986. The UnitI Plant machinery...

solid waste generation in cement grinding unit

The reduction in clinker factor is achieved by cogrinding cement clinker with supplementary cementitious materials, such as fly ash, slag, natural pozzolanic materials, and equipment nor additional unit operations, and existing Portland cement plants can be used older generation coolers....

79. MINICEMENT PLANT Embassy of Ethiopia

The anticipated minicement plant will start its operation at 75% in the first year, 85% in the second year, and at in the third year and thenafter. The detail is shown in Table ... The technology of cement production involves several unit operations, and are complex to enumerate. However, the major unit operations are the following:...

Design of Cement Plant Waste Heat Recovery Generation

Design of Cement Plant Waste Heat Recovery Generation ... describes heat recovery unit operations modelling using Aspen ... existing cement plant and available space, water resources, ......