cement process coal mill

Cement Vertical Mill Flow Sheet | Crusher Mills, Cone ...

cement plant coal mill grinding flow sheet – Basalt Crusher. about cement plant coal mill grinding flow sheet. . A vertical cement mill with a high efficiency separator will be used for raw coal grinding and ....

Cement Process Chemistry SlideShare

Process Overview Mining Crushing Raw Mill Grinding Raw Meal Homogenization Pyro Processing Clinkerization Final Grinding Packaging Crushed Limestone Additives Iron ore or Clay Coal Ash From Coal Fired Fine Raw Meal (120)Res. < 3% Lt. wt Clinker 1) Gypsum 2) Flyash 3) Pozzolona 4) Slag 1) OPC 2) PPC 3) Slag Cement Blaine 300350 ......

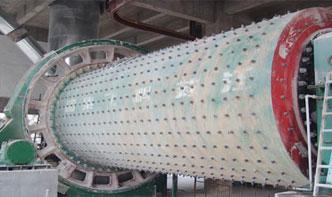

Cement Mill Great Wall Corporation

The cement mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on. Our company has more than 40year experience on the manufacture of cement mill ......

coal mill cement

Sep 03, 2018· Lafarge Africa Plc (LafargeHolcim) is erecting a new Loesche coal mill at its Ewekoro cement plant in Nigeria. The new mill will grind local lignite and petcoke. The mill has a grinding capacity of 23tph at 23 per cent R90μm for coal and 16tph at three per cent R90μm....

Cement Making Machinery,Rotary Kiln,Cement Mill,Lime Kiln ...

Coal Mill is the main equipment of the rotary kiln cement clinker production system and at the same time, it is also suitable for powder grinding equipment system in such industries as thermal power plant, metallurgy, chemical industry and sugar industry....

Products_Turnkey cement plant suppliers|Ball mill|Rotary ...

Mining Mill Air Swept Coal Mill Drying Raw Mill Wet Raw Mill Semi Autogenous Mill Autogenous Mill Raw Mill *13m Mining Ball Mill for Slag Φ * 13m Mining Ball Mill for Slag Φ*13m Super fine slag mill Slag Ball Mill Ф5x15m Cement mill Ф cement mill Ball Mill for Cement Grinding Φ*13m Ball Mill for Cement Plant...

Coal Mill Process Equipment For Coal Mill

Coal Mill for sale, Coal Mill Process, Coal Mill Machine. Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in cement plant for both drying and grinding of the powders....

Cement making process Great Wall Corporation

Coal Mill Raw material mill Cement Mill Rod Mill Rotary Kiln Vertical lime kiln Rotary Kiln Lime Rotary Kiln Cement Rotary Kiln Rotary dryer Casting Parts Slag Pot ... Since the raw meal grinding work takes up more than 30% labor force in the whole dry process cement production line, ......

DETAILED ENERGY AUDIT AND CONSERVATION IN A .

these have been wholly converted to dry cement process and modern technology. ... both for raw meal as well as coal. Cement grinding is ... it is evident that the cement mill section (37%) is the major contributor to overall SEC, followed by kiln section (26%) and then by Raw mill ......

PFRM() Vertical Mill_Turnkey cement plant suppliers ...

Therefore, secondary grinding is unnecessary for largescale and medium vertical mill. 4. Stable chemical composition and even particle size products. 5. Simple process flow and small in size. There is a segregator in the vertical mill, which makes powder separator and elevator unnecessary....

Process Fans Used in Cement Industry

Process Fans Used in Cement Industry Neel Rao. 22 January 2016 ... Coal Mill Fans. In cement industry coal mill fans are used to supply required air for burning coal and remove the exhaust gases produced after burning. These fans help in effective burning of coal inside the mill. ... In addition to these key process fans, cement industry also ......

firefiting system in coal mill International Cement Review

Re: firefiting system in coal mill. If the coal mill temp goes high, it can ignite the coal and result in explosion inside the mill and components. Thats why the CO2 is injected into the mill to create a inert condition, means to reduce the Oxygen content inside the mill to avoid any firing/explosion....

Thermal Energy Audit of Kiln System in a Cement Plant

Thermal Energy Audit of Kiln System in a Cement Plant ... Energy audit of kiln system in a cement plant is conducted by; using data measured from a typical cement plant ... raw mill and coal mill. II. PROCESS DESCRIPTION MINES At about a distance of from plant the plant is having its own mining facility. For convenient...

Coal Mill Safety | Combustion | Coke (Fuel)

Coal Mill Safety Download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. ... General Safety Rules Ignition Process Coal absorbs oxygen from atmosphere ... Thermal Energy Efficiency in Cement Industry. Uploaded by. Hoang Nguyen. Kiln Uploaded by....

coal mill for cement plant

coal mill in cement plant Coal Mill in Cement Plant manufacturer in China,Shanghai is a professional ore crusher equipment,Coal Mill in Cement Plant manufacturer in China, mechanical beneficiation equipment, ore milling equipment mining process, the first belt conveyor, vibrating feeder, conveyor equipment ......