cost of setting up a cement plant in usa

Opening a Precast Concrete Business How to Open a ...

A precast concrete plant startup is no small endeavor. Before you can seriously consider opening the doors on a new operation, there are a multitude of issues ....

Why Precast Costs Less National Precast Concrete Association

Why Precast Costs Less. ... .what is the machinary cost in india?,when making or manufacturing,the plant of precast concrete . ... Most of the cost is in the casting tools, cranes and the cement plant. Feel free to contact me and we set up JV partnerships around the globe with serious builders. Kind Regards, Andrew Bales. Reply. Ram says....

Manufacturing Facilities Proposal Wisconsin Public Service

Manufacturing Facilities Proposal. 1 Construction proposal ... This proposal includes floor plans, timetables and construction costs for conventional and preengineered buildings. Plans are based on the following: • Typical manufacturing layout ... (plant sealed concrete) • Ceiling fans in plant • Doors, frames and all hardware ......

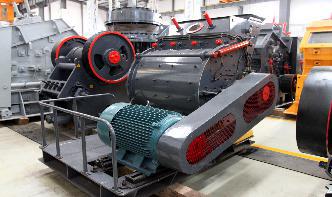

Central Mix Plants | BMH Systems

BMH Systems designs and manufactures customized Central Mix Plants, also called Wet Concrete Batch Plants, that meet any capacity and requirement, whether you're planning to retrofit existing facilities or start from the ground up....

How to Make Your Concrete Business Successful |

Jun 30, 2017· Every shovelful of concrete costs money, as does every tool you supply for your employees' use. ... articles and new manuals to stay up to date with the ....

Swimming Pool Cost Pricing Landscaping Network

Swimming Pool Cost Custom Backyard Pools Pool Shapes Swimming Pool Plants Swimming Pool Design ... costs go up. Very often the spa is part of a water feature where the two water bodies meet. ... Boulders are installed in three different ways: set atop the pool edge (low cost), integrated into the deck and coping (medium), or dropped down to the ......

Standard Custom Precast Concrete Buildings by EasiSet

These buildings allow the option of being fully outfitted in the plant prior to delivery. EasiSpan: Larger OnSite Assembly EasiSpan's durable and secure prefab commercial buildings use EasiSpan roof panels to achieve clearspan widths of 20', 24', 30', 40' and 50' with lengths up to ....

How Portland Cement is Made? Manufacturing Process of ...

Lime and silica make up approximately 85% of portland cement. The materials that are commonly used are limestone, shells, chalk, shale, clay, slate, silica sand, and iron ore. Since limestone is the main component, often cement plants are located near limestone quarries....

Tylden Equipment Portable Concrete Plants

Fixed models for bolting to concrete or skid frame models for placing on crushed rock. These models are generally suited for the larger, longer and high volume projects where set up and demobilizing costs can be dispersed over the higher volume, We have front end loader plant designs from 30m3 per hour right through to 100m3 per hour. Larger production rate models can be tailored for your requirements....

Cement Manufacturing Process | Phases | Flow Chart ...

Cement Manufacturing Process Phases. ... Generally cement plants are fixed where the quarry of limestone is near bye. This saves the extra fuel cost and makes cement somehow economical. ... During grinding gypsum is also added to the mix in small percentage that controls the setting of cement. Rotating ball mill. Cement Manufacturing Process ......

Buying Concrete 12 Tips to Determining Project Success ...

The concrete will set faster than you can mix and pour it, and you'll end up with a poor pour and a nasty finish (unless you are willing to work in phases over time). Readymix is a nobrainer for mid to large projects, but what about cost? If you use 60pound bags, concrete for a ....

Study of Equipment Prices in the Power Sector ESMAP

Impact of Plant Size on Technology Cost 9 3. Assessment of Price Trends for Generation Plant Equipment 13 Impacts of Increase in Heavy Construction Projects in the United States and Overseas 13 Trends in Cost Indexes for Power Plant Equipment and Materials 15 Trends in Escalation for Power PlantRelated Items in India and Romania 16...

World Class Manufacturing:Plant Start Up and Commissioning ...

Essential Ingredient of World Class Manufactring is a procedure for plant start up and commissioning. It is observed that the maximm damage in the life of a plant occurs at start up and the remnant effect of this damage to life an be significant....

Becoming a Brick Manufacturer Startup Biz Hub

Sir, I am planning to set up mud brick making plant with capacity 8000 to 10000 /8 hours, please give me information about machine cost kiln cost. suitability whether import from china or purchase from south India cost comparison service....

Power Plants: Characteristics and Costs

Power Plants: Characteristics and Costs November 13, 2008 Stan Kaplan Specialist in Energy and Environmental Policy ... energy statistics and forecasts for the United States. The estimated amount of new generating capacity is taken from the Excel output spreadsheet for the Annual Energy...

Seven MustUse Concrete Admixtures (Additives)

These types of concrete admixtures are commonly used to reduce the effect of high temperatures that could produce a faster initial setting of concrete. Set retarding admixtures are used in concrete pavement construction, allowing more time for finishing concrete pavements, reducing additional costs to place a new concrete batch plant on the job ......

Concrete Mix at

High Performance Cement by Quikrete High Performance Cement 60lb Fast Setting Concrete Mix CA Residents: Prop 65 WARNING(S) Enter your location. for pricing and availability. ... Sign up for exclusive offers, tips and more. Sign Up. SIGN UP SAVE Email Includes: ... Contact Us Lowe's Credit Cards Gift Cards Rebates Returns Exchanges ......

Batch Plant and Central Mixer Operations Manual CONE .

work off of a minimum and maximum setting. The settings for this need to be determined for each plant individually. Initial OpenThe initial open setting is used to get the gate opened at the start of discharge. Typically the initial open setting should get the gate ¼ 1/3 of the way open with the first pulse or to get a good flow rate started....

DM100 Stonemaker (Brick, Block and Concrete Making Machine)

Uses local aggregate to manufacture low cost concrete products; Works anywhere, easy to operate and inexpensive to run ... 100's of blocks every hour. And by an easy conversion to wet cast production, the DM100 is able to produce ready mix concrete at a rate of up to 3 cu/yds per hour. ... for onsite assistance with factory set up and ......