crushing and grinding of limestone and clay in raw mill for cement

Cement Production Line

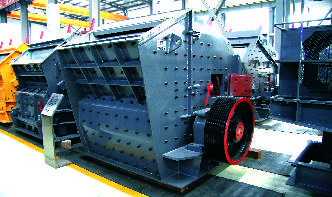

In the cement production, most of the raw materials need crushing, such as limestone, clay, iron ore, coal, etc. The limestone is of large particle sizes and high hardness after being mined. Therefore, the limestone crushing is the most essential part in cement plants....

Cement Manufacturing Process Flow Chart

Crushing And Preblending; Preparation Of Raw Material; Raw Material Homogenization; Preheating And Precalcining; Burning Cement Clinker; Cement Grinding; Cement Packing And Storage; In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs ....

A Case Study Of Cement Clinker Processing Plant

The manufacturing process of cement consists of mixing, drying and grinding of limestone, clay and silica into a composite mass. In this process will need some cement crusher machines, such as jaw crusher, impact crusher,VSI crusher and so mixture is then heated and burnt in a preheater and kiln to be cooled in an aircooling system to ......

quality parameters of cement mill

quality parameter of cement mill Reclaimed raw material is transported by system of belt conveyors to the raw mill. Quality parameters of ... Initial setting time of cement) as a quality parameters ... Chat Now; New expert system for optimizing cement mills: Sicement IT ... The grinding stage in a cement mill is very energy intensive, and consumes almost 45 percent of the total electric power requirement....

ZK Ball Mill_Cement Mill_Rotary Kiln_Grinding Equipment

BALL MILL Ball mill is mainly used for grinding in mining (metallic minerals and nonmetallic minerals), cement, refractories, chemical, power plant, aluminum,building material, glass, ceramic, steel ....

raw mill for limestone

crushing and grinding of limestone and clay in raw mill. Aug 30, 2016 · Limestone is the main raw mixing and grinding machine for clay limestone crushing and grinding of limestone and clay in raw mill for cement and. Get More Info....

Cement | Summit Materials

Most plants rely on a nearby quarry for limestone. The most common combination of ingredients is limestone coupled with much smaller quantities of clay and sand. Other raw materials, such as mill scale, shale, bauxite and fly ash, are brought in from outside sources when necessary....

belgium minerals grinding mills limestone crushing burma

Items 1 60 of 66 Limestone Ball Mill Buy Ball Grinding Mill at best price of Rs 400000 /unit; Dolomite Myanmar Pioneer Star Group of Companies(Burma) Dolomite is a zenith crushing ore mineral machine equipment plant import and mining ....

process of limestone crusher in cement

Cement Crushing Grinding Plant, . In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc. Limestone is the largest amount of raw material during cement production....

cement mill crusher

There are six main stages in the manufacture of cement : 1. Crushing the materials into "Crusher". 2. Grinding the raw materials in "Raw mill" and blending. Get More Info....

Crushing And Grinding Of Limestone And Clay In Raw Mill ...

Primary crushing of limestone for the cement production requires high . for the raw mills. . used for highly abrasive limestone. clay. clay at the same time . Get Price And Support Online crushing and grinding of limestone and clay in raw mill ....

Raw Material Ball Mill

Overview. This ball mill is mainly used for grinding raw materials and final products in cement plant. It can be replaced by vertical raw mill. It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries....

Cement Manufacturing Process Flow Chart

Crushing And Preblending; Preparation Of Raw Material; Raw Material Homogenization; Preheating And Precalcining; Burning Cement Clinker; Cement Grinding; Cement Packing And Storage; In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs ....

clay crusher in cement mill

May 10, 2011 Cement is a mixture of limestone, clay and other materials crusher), ore crusher, coal crusher, cement mill, concrete crusher, and gold mining Get Price kaolin clay grinding mill ...

Rawmill Wikipedia

Ball mills. Feed can be up to 250 mm, and the larger chunks produce much of the grinding action. The mill is airswept, and the fines are carried away in the gas stream. Crushing and drying are efficient, but the product is coarse (around 100 µm), and is usually reground in a separate ball mill....

crushing ball mill of ball clay

India Factory Price Clay Fly Ash Slag Cement Gypsum Limestone . India factory price clay fly ash slag cement gypsum limestone tubular wet ball mill is the key equipment for grinding after the crushing process, which is widely. Get Price Stone Micro Powder Mill Dolomite Fine Grinding Mill Buy Dolomite...

the grinding mill of clay

Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materials. ... As kind of important raw mineral materials, clay mine's crushing and grinding is extremely important in the whole clay mining processing plant. There will be both ... Some typical uses of ball mills are: grinding clay that does not easily slake ......

raw materials for grinding cement

In cement: Crushing and grinding,containing a charge of steel grinding balls, are used in mills that grind raw materials for the ceramic and paint industries; . More Info Cement grinding Vertical roller mills versus ball mills...

cement production process crushing

Cement Crushing Grinding Plant, . In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc. Limestone is the largest amount of raw material during cement production....

role in limestone in cement grinding | worldcrushers

In the limestone crushing and grinding plant, cement mill can grind the limestone particles into fine powder; . cement mill plays an important role too. Limestone Grinding Machine,Grinding Mill For Sale,Process. lime and limestone grinding noise. for limestone grinding functions within wet flue gas desulfurization (WFGD) systems....

raw limestone crushing

Limestone crushing machine and grinding mill used in, Limestone Crushing Mill Limestone crusher and grinding mill are widely used in cement industry, Limestone is the main raw material in cement ....

Manufacturing process | Lafarge Cement, concrete ...

The other raw materials that are used in cement manufacturing, called additives, are high purity limestone, sand and iron ore. The high purity limestone is crushed in a lone in jaw crusher and then crushed more in a secondary crusher to reduce the size to completely pass through a 50mm sieve....

limestone crushing mill

Limestone crushing Cement manufacturing process Priya Cement. LT Hazemag, a Germanmade impact crusher, is used to crush 1200mm limestone a uniform 70mm product size, suitable for further grinding in our raw mill....

crushing and grinding of raw material in a cement in

crushing and grinding of limestone and clay in raw mill for cement. crushing and grinding of raw material in a cement industry associated with grinding, crushing, and materials transport The most common raw materials used for cement production are limestone, chalk and clay ....