drawing of a value stream mapping in the mining industry

Product Development Value Stream Mapping (PDVSM) .

In traditional factory value stream mapping, the only explicit stakeholder of importance is the buyer of the product of the factory (a/k/a "the customer"), and his or her expectations are assumed to be simple—a certain number of units in a given amount of time, on time, and to some standard of quality....

Best Practices for Using Value Stream Mapping as a ...

Best Practices for Using Value Stream Mapping as a Continuous Improvement Tool By R. Keith Mobley, CMRP Principal SME, Life Cycle Engineering Value steam mapping is a visual means to depict and improve the flow of manufacturing and production process, as well as the information that controls the flow of materials through the process....

How to Create a Value Stream Map | Lucidchart Blog

A value stream map is a flowchart that illustrates and analyzes the steps involved in producing a product or delivering a service. Once someone maps the current state of the process from beginning to end, he or she should find areas that do not add value to the process and ....

Value Chains, Value Streams, Value Nets, and Value ...

Order fulfillment, for example, is a value stream: the input is the order, and the results are the delivery of ordered goods. Order entry is one activity in the collection of activities that constitute the order fulfillment value stream. A value stream is a collection of activities that function together....

IMPLEMENTATION OF A LEAN MODEL FOR CARRYING OUT .

CARRYING OUT VALUE STREAM MAPPING IN A MANUFACTURING INDUSTRY ... for carrying out Value stream mapping in this industry was devised. The model proposed for ... adopted to draw the Current State Map. • Identification and drawing the product flow from the rawmaterial entry point of the...

Where do "Value Stream Maps" come from? Michel Baudin's Blog

"Value stream mapping, for instance, is perhaps the most widely used tool in lean programs today. The prevailing assumption in virtually every plant is that a value stream map must be drawn for each product family, a value stream manager anointed, and that it will somehow magically reveal all ....

IMPLEMENTATION OF VALUE STREAM MAPPING IN AUTO .

IMPLEMENTATION OF VALUE STREAM MAPPING IN AUTO ANCILLARY INDUSTRY TO REDUCE CYCLE TIME Deva Prince1, K., S. Kathiresan3, ... Value Stream Mapping has the reputation of uncovering waste in manufacturing, ... while mapping job shop operations using a standard VSM andalso explained while drawing a VSM of a process,...

A crosssector review on the use of value stream mapping

Value Stream Mapping (VSM) has become a popular method for lean thinking and implementation in recent years. ... between the service industry and the manufacturing industry is the intangibility and heterogeneity of the outputs of services. The measurement of service is dominated by nonphysical elements. ... Drawing the future state map (FSM ......

Value Stream Mapping | Creative Safety Blog

One of the nicest things about value stream mapping is that it can be done in a variety of ways by manufacturing and industrial companies of all types and sizes. Some places will begin with a simple pen and paper to draw out their value stream mapping. Others use complex software which allows for the detailed creation of a value stream map....

Value Streams (Part 1) Value Stream Process Mapping ...

Value stream mapping is at the heart of TPS or Lean. Using the Time Observation Sheets you will learn how to fill out a Value Stream Map, including determining WIP (work in progress) depicting physical movement and process flow along with information flow, and assessing when work is valueadded and when it is nonvalue added....

แผนผังสายธารคุณค่า (Value Stream Mapping (VSM))

Analyzing the benefits of lean manufacturing and value stream mapping via simulation : A process sector case study. Int. J. Production Economics. 2007; 107(1): 223236....

A Review Methodology of Value Stream Mapping

A Review Methodology of Value Stream Mapping 1Palak P. Sheth, 2Vivek A. Deshpande ... Based on processes apply the steps and draw a future state map and it describes the proposed/future position of shop floor of ... Nitin Pandhi, Sanjiv Verma, "Value Stream Mapping in Automotive Industry", IJCET, Vol2,, 2012...

Value Stream Segmentation and New Product Development

Vaughn, Richard Lee, "Value Stream Segmentation and New Product Development. " Master's Thesis, University of Tennessee, 2015. ... Value Stream Segmentation and New Product Development A Thesis Presented for the Master of Science ... of "value stream segmentation" is how a company should use value stream mapping to streamline its processes ......

Value Stream Mapping Solution |

Valuestream mapping is a widely used leanmanagement method. It is used mainly for analyzing the current state for the series of events that take a product/service from ....

Lean Manufacturing Diagrams | Value Stream Mapping Software

Value Stream Mapping solution can be used for drawing flow diagram in great detail every step of a manufacturing process. This graphical representation of a process is a powerful tool that helps in the diagnosis of process efficiency and allows companies to develop improved processes....

Value Stream Mapping: A Case Study Of Assembly Process

Value Stream Mapping: A value stream is a collection of all actions value added as well as nonvalue added that are required to bring a product or a group of products that use the same resources through the main flows, from raw material to the arms of customers .These actions are...

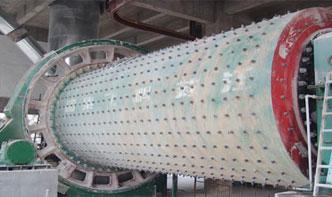

value stream mapping in the mining industry

value stream mapping in mining and mineral process. Value Stream Mapping in the Service Industry :, Value Stream Mapping in the Service Industry, getting into the detail of the process is crucial if your value stream mapping exercise, Value Stream Mapping ....

Using Value Stream Mapping in the service industry ...

Value stream mapping at its heart is the mapping of information and material flow throughout an organizations production process (bear in mind the production process doesn't have to be manufacturing it can be administrative tasks (such as raising a purchase order) or ....