five machining works in a lathe machine

What Is CNC Machine? Working Principle Of CNC systems ...

CNC machine is most useful for complex machining. Not only the metal works, CNC machine is used for woodworking also as a single machine tool. To keep pace with the modern world, machine tool industries are introducing computerization by a CNC machine, ....

Applications of CNC Machines. Types of CNC Machining Center.

All these metal removal works are performed by different machine tools like lathe, milling machine, drilling machine, boring machine, shaping machine, reamer, etc. Traditionally these machines are operated by the operators, but the CNC versions of all these machines are now used extensively....

Chapter 5: Formulas and Calculations for Machining ...

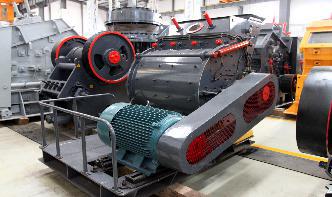

TURNING OPERATIONS. Metal removal from cylindrical parts is accomplished using standard types of engine lathes or modern machining centers, the latter operated by computer numerical control (CNC). Figure shows a typical large gearedhead engine lathe with a digital twoaxis readout panel at the upper left of the machine....

FiveAxis Performance from a FourAxis Machine

FiveAxis Performance from a FourAxis Machine Adding a FifthAxis Rotary Table Can Create Aerospace Manufacturing Opportunities for Machine Shops Many machine shops may avoid taking on intricate aerospace machining work because they have already made investments in fouraxis machining centers, and aerospace work mostly requires fiveaxis ......

HOW TO GET CNC MACHINING WORK?

Feb 10, 2005· With more than million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers....

Advantages of CNC over Conventional | Fairlawn Tool, Inc.

A CNC machine is a machine that utilizes Computer Numerical Control over machine tools like lathes, routers, grinders or mills. ... One programmer at the computer console can command machine work that would be the equivalent of multiple operators on lathes, grinders, routers, mills and shapers. ... while CNC machining works by cutting and ......

Working Principle of Lathe Machine Engineering Tutorials

Working Principle of Lathe Machine October 18, 2009. ... The cutting tool may also be fed at an angle relative to the axis of work for machining tapers and angles. Construction: The main parts of the lathe are the bed, ... Types of lathes Engineering Tutorials December 6, 2014 [.] Lathes are available in large variety of types and sizes....

5 axis CNC machine | Wiki Machine

March 6, 2017 All about 5 axis machining, 5 axis cnc machines, 5 axis cnc machining center, horizontal 5 axis cnc machine, vertical 5 axis cnc machine, 5 axis machining shops....

Eccentric Work on the Lathe | Smithy Detroit Machine Tools

If the workpiece is large enough to position all center axes on the work at the same time, the machining operation will be simple and easy. • First determine the stock required by adding the throws plus 1/8 inch for machining (Figure 3102)....

Understanding SwissType Machining : Modern Machine Shop

Understanding SwissType Machining. ... The machine feeds the work out of the spindle and past the tool as it goes. This makes the CNC Swisstype particularly effective for long and slender turned parts. ... 5. Amazing machining cycles....

CNC Machining, CNC Milling, Fabrication Services ...

CNC Machining, Turning, and Fabrication Services . ... which often requires combining forming techniques with machining and other operations. We work with a variety of materials including alloy steel, aluminum, copper, brass, and machinable plastics or composites. ... Okume Lathe. Tree Lathe. Okume Mill. Mills. Bridgeport 2 HP Knee. Lathes....

Large CNC Machining Equipment (Hor., Vert., Lathe)

KM Machine #125 Mitsubishi MAF180C Horizontal Boring Mill. KM MachineFabricating Inc.'s Machine #125 is a large CNC horizontal boring mill ideal for large machining work. It is a Mitsubishi MAf180C, capable of handling a part 12 meters long, 5 meters high and 4 meters wide weighing up to 132,000 pounds....

Why 5axis? The benefits of switching to a 5 axis machine

Every shop has work that would benefit from a 5axis machine because a 5axis machining center facilitates 5sided machining. So, even if you don't have simultaneous 5axis work, such as impellers or turbines, the parts you are producing on your 3axis machines will be more profitable when you use 5sided machining on a 5axis machining center....

Lathe, Lathe Operations Types Lathe Cutting Tools

Lathe Operations Types and Cutting Tools August 26, 2015 Machining Operation and Types of Machining Tools August 26, 2015 Milling Machine Definition, Process Types August 7, 2015...

Industrial Job Works Lathe Machine Job Work Manufacturer ...

Industrial Job Works We are the one of the most well known service providers, conducting all types of Lathe machine Job Works for the clients. We use the best available quality raw material along with the latest machines and technology to undertake these works....

CNC Machine Shop Wire EDM | 5 Axis Milling | Aircraft Parts

Super Precision Lathe Work; Contact our Wisconsin CNC Machine Shop to learn more about our capabilities and get your project started today. ... Whether you need prototype or production machining work, Owens will deliver the highest quality services producing the complex and tight tolerances for your component demands....

Machinery Ballard Machine Works

Machinery. Ballard Machine Works > Machinery. Kitamura Mycenter 4xd CNC Milling Machine. 4 axis CNC Milling Machine with Aaxis rotary table 44″ x 24″ x 24″ travels. 15,000 RPM 40 taper spindle TSC. ... 6 axis CNC Lathe ″ bar capacity, with live tooling, Yaxis and sub spindle....

Lathe machine: Main Parts, Operation and Working Sitemap

Lathe machine is a basic machine which is used in every metal forming industries. It is combination of many parts which works together to perform a desire function. A lathe machine is used to machine cylindrical work piece which is 360 degree symmetrical form the axis of rotation....

CNC Machining Intro to CNC Machining UFL MAE

5. For each part feature, select the appropriate tool from the library and set the parameters necessary for machining that feature. Typical parameters include spindle speed, depth of cut, feedrate, number of passes, tool path pattern, etc....

Lathe Parts Page 1 Lathes + Machine Tool Archive

How the lathe works. Names of lathe parts. Screwcutting. Generating changewheel charts. countershafts. ... at least on a conventional machine. On the main spindle of the lathe, the one carrying the drive pulley, will be found a large gear, generally referred to as the "Bull Wheel". The Bull Wheel is attached to the pulley by a nut and bolt, a ......

Horizontal Machining | Machining Centers | TurnCut for ...

TurnCut works without additional motors, servos, and heavy attachments, and integrates with tooling already developed and readily available. TurnCut enhances the use of the machine without adding components or weight that may restrict its use during normal CNC machining operations....

What are CNC Machines? How CNC Machine Works?

The computer thus knows what exactly is to be done and carries out all the cutting processes. CNC machine works like the Robot, which has to be fed with the program and it follows all your instructions. Some of the common machine tools that can run on the ....

Prototype Lathe Parts Turned Parts in 5 Days Standard!

Rapid Machining is an industry leader in machining prototype CNC lathe parts. The turning process is typically used when prototype parts require a cylindrical pattern, parts are often machined out of soft metals and plastics....

Do I Need 3, 5, or 9Axis Machining? – Temco Tool Blog

9Axis Machining. 9axis CNC is a blend of lathe and 5axis machining. With 9 functional axes, the part can be turned and multiaxis milled in a singular setup. The largest benefit of this type of machine is the elimination of manual loading and secondary fixtures. A multiaxis machine like this can make a ....

Balaji Lathe

Machining Solution; How To Select Lathe Machine; ... Since then company is redefining all three prime key points with its lathe machine products with the brand names of "Balaji Lathe". The gradual and steady progress towards its vision to satisfy the primary requirements Precision, quality and time bound delivery, in its products, Vinit ......