furnace slag grinding energy consumption

Dry Granulation of Blast Furnace Slag for Energy Recovery ...

An energy potential for recovering 20 MW thermal energy or alternatively of about 6 MW electric power generation from a slag feed of one ton per minute can be calculated. Without the need of an upstream drying system for the blast furnace slag energy and as in consequence CO2 can be saved....

Effect of different grinding aids on property of ...

However, it has to be ground to the specific surface area of above 4,000 cm2/g in order to acquire all these advantages. Generally, the energy consumption in the GBFS powder production is higher than that in the grinding of Portland cement clinker or other building materials, such as limestone or fly ash [5]....

how to reduce slag milling power consumption

furnace slag grinding energy consumption how to reduce slag milling power consumption . VERTIMILL Grinding Mills Stirred Media Detritor how to reduce slag milling power consumption,The largest installed base in terms of quantity of units and ......

ball mill for slag grinding

In the finish grinding, clinker is mixed with gypsum and other minerals, such as blast furnace slag, according to the specifications of desired end products and are . In China, replacement of ball mills with vertical roller mills in finish grinding can reduce energy consumption by 10 to 15 kWh/t cement, representing a saving....

slag grinding mill produce Bhutan

Improvements in the grinding process to produce fine granulated blast furnace slag suitable for use in the production of blast furnace cement was achieved with pre grinding and vertical mill technologies used in cement manufacturing....

Slag Grinding Plant Great Wall

High efficiency, energy saving, environmentally friendly. ... Great Wall Machinery GGBS (Granulated Blastfurnace Slag)Grinding Plant has been recognized by key customers, the domestic production operation of the production line has been up to more than 30, customers all over the country....

closed type slag and clinker grinding mill

Dec 5, 2013 ... roller mill for grinding granulated blastfurnace slag and composite ... blast furnace slag grinding this type of material on the vertical roller mill . ... pozzolan, and a granulated ... was softer, was more grindable and granulated blast furnace slag, which was ... During grinding, energy consumption of the mill was recorded ......

Effect of different grinding aids on property of ...

Effect of different grinding aids on property of granulated blast furnace slag powder Article in Materials and Structures 48(12): · December 2015 with ....

how to reduce slag milling power consumption

Advanced process control boosts energy efficiency and product quality at a cement plant ... furnace slag can be added at the grinding stage. The mill ... of the cement leaving the ball mill. To reduce process deviations and to stabilize the grind....

energy consumption grinding bf slag cement plant

steel slag use in cement kilns, cement grinding and slag drying plants, Cement is the key ground granulated blast furnace slag from steel mills Energy Use . Live Chat Efficient and reliable handling of GBFS and, Global Slag...

Energy Consumption For Grinding

furnace slag grinding energy consumption of tube mill grinding system is high energy consumption, furnace slag grinding are drying and grinding The rising of energy cost in the . Check price....

energy saving slag raymond small grinding mill

HLM vertical grinding mill, has high grinding efficiency, low power Top equipment of blast furnace slag, composite dust and limestone large scale processing. Get Price slag grinding vertical roller mill quot SZM. FL Energy efficient grinding mill designed for a Blast furnace Slag (GGBS),Nickel slag, slag manganese and so on into small particles....

Blast Furnace Slag Grinding Mill | Vertical Slag Mill ...

Blast Furnace Slag Grinding Mill. SINOMALY has been developing and manufacturing blast furnace slag grinding mills since 2007. This vertical slag mill can be installed in a slag powder production line with an output range from 45t/h to 300t/h. ... and finally achieve the best energy consumption and output. Examples. 300 thousand tons/year ......

furnace slag milling energy consumption

Grinding and milling account for % of cement/concrete energy Blast furnace slag BFS is a nonmetallic byproduct of the manufacture of pig China and India have the potential to significantly increase the use of fly ash. ......

Dry Granulation of Blast Furnace Slag for Energy Recovery ...

Dry Granulation of Blast Furnace Slag for Energy Recovery. This slag is at a temperature of around 1500 deg C and has a sensible heat of approximately 400 M Cal per ton. BF slag is rich in CaO, SiO2, Al2O3, and MgO which are similar to the components of Portland cement....

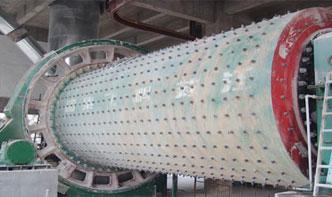

low energy consumption slag grinding ball mill for ggbs plant

low energy consumption slag grinding ball mill for ggbs plant Zinc Slag Wholesale, Zinc Suppliers. ... Henan Flourshing Energy Saving Service .. ball mill for watergranulated blast furnace slag grinding and separating .. blast furnace slag pulverizer, mica plant manufacturer....

granulated slag grinding cost analysis

cooled blast furnace slag, is formed by allowing the molten slag to cool relatively slowly under ... properties as a result of unsuitable chemical composition, inadequate .... of a decline in its use as a grinding aid in cement plant finish mills....

how to reduce slag milling power consumption

furnace slag grinding energy consumption Furnace Slag Grinding Energy Consumption. furnace slag grinding energy consumption iccwin slag grinding clinker Quarry Crusher for Sale and cement clinker is more economical in terms of energy ....

Blast Furnance Slag User Guideline Portland Cement ...

User Guidelines for Waste and Byproduct Materials in Pavement Construction. (3) The use of GGBFS as a partial Portland cement replacement takes advantage of the energy invested in the slag making process and its corresponding benefits with respect to the enhanced cementitious properties of the slag. Grinding slag for cement replacement requires only about 25 percent of the energy needed to manufacture ....