grinding impacts during cement manufacturing

grinding process in manufacturing cement

Joseph Aspdin first made portland cement in his kitchen stove in . Manufacturing Portland Cement. . Gypsum is added during the grinding process to control the set . Cement Manufacturing Process, Mill (Grinding), Cement Manufacturing Process Free download as ....

Recent Progress in Green Cement Technology Utilizing Low ...

The major environmental impacts related with cement include energy required for manufacturing, direct and indirect greenhouse gases emission during production and transportation of clinker, mining of natural resources, and waste generation....

ENVIRONMENTAL IMPACT ASSESSMENT FOR THE .

PROPOSED DEVELOPMENT OF A CEMENT GRINDING INDUSTRIAL DEVELOPMENT ZONE, PORT ELIZABETH April 2013 ... will look at the potential environmental impacts the proposed Cement Grinding Facility ... during the development of site establishment and the construction phase of the...

Portland cement Wikipedia

Portland cement is the most common type of cement in general use around the world as a basic ingredient ... Cement grinding ... 2 by modification of the chemistry of cement, by the use of wastes, and by adopting more efficient processes. Although cement manufacturing is clearly a very large CO 2 emitter, concrete (of which cement makes up ......

What Is Cement? Manufacturing, Composition their ...

Function of Tetracalcium Aluminoferrite. Assist in the manufacture of Portland Cement by allowing lower clinkering temperature. Also act as a filler contributes very little strength of concrete eventhough it hydrates very rapidly. Also responsible for grey colour of Ordinary Portland Cement....

A Review On Environmental and Health Impacts Of Cement ...

It can be accomplished by any of three processes: the dry process, the wet process, or the semidry process [10]. In a dry cement manufacturing process, dry raw mix contains less than 20% moisture by mass. However, in a wet process water is added to the raw ....

Environmental Impact of Carbonated Calcium Silicate .

Environmental Impact of Carbonated Calcium Silicate CementBased Concrete N. DeCristofaro1, V. Meyer2, S. Sahu3, ... EMISSIONS DURING CEMENT MANUFACTURING ... 3. the generation of electricity needed to drive the kiln, the grinding mills and materials transportation systems. As stated earlier, the CO ......

(PDF) Analysis of material flow and consumption in cement ...

Analysis of material flow and consumption in cement production process ... production stages using actual plant data received from an existing cement manufacturing facility. ... During cement ......

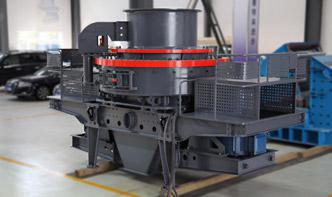

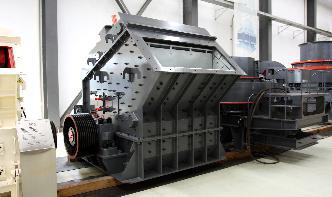

grinding mills for cement production

Learn more about our production processes How we make cement Learn more about how we manage the impacts of our production . Read More; Cement mill ... CO 2 emissions during transport could be reduced by replacing diesel fuel with biodiesel. Normally, energy efficiency improvements ... (Grinding) Cement. Cement Manufacturing Process Free ......

KESORAM INDUSTRIES LTD CEMENT DIVISION UNIT: .

cement manufacturing process Manufacturing process involves Crushing, grinding and mixing of limestone with additives like bauxite and iron ore into a powder known as "raw meal"....

SikaGrind Technology

The importance of cement formulation and grinding process in cement manufacturing Cement manufacture is a highly technical process in which every part has a decisive impact on the product quality as well as on economical and ecological production parameters. From the origin of the necessary...

cement grinding process in details

During the design and production of our mills, we monitor every single detail, Christian Pfeiffer is your expert for grinding processes, plants, and all components, learn about the latest developments in the field of cement grinding and get.......

Cement Manufacturing YouTube

Jul 31, 2013· Cement Manufacturing 7activestudio. Loading... Unsubscribe from 7activestudio? ... Clay which provides aluminium and is manufactured by ....

of

process of manufacturing PPC involves grinding of Clinker, Fly Ash and Gypsum in the ratio of 65:30:5, OPC involves grinding of Clinker Gypsum in the ratio of 95:5 SPC involves grinding of ClinkerSlag – Gypsum in the ratio of 30:65:5 in the Cement Mill....

Cement Milling Understanding Cement

Cement milling and gypsum dehydration. Because the cement gets hot due to the heat generated by grinding, gypsum can be partly dehydrated, forming hemihydrate, or plaster of Paris 2CaSO 4 .H 2 O. On further heating, hemihydrate dehydrates further to a form of calcium sulfate known as soluble anhydrite (~CaSO 4 )....

Powtech 2019 : Bagging packaging

11 天前· Cement Manufacturing Technology; Grinding Milling Systems ... closed packaging protects highly sensitive products from loss and secures the quality against environmental impacts. ... 40 times greater than paper sacks • Safe outdoor storage in all seasons • Up to 11 per cent fewer packaging damages during transport and handling ......

grinding plant process cement

gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the ... "Grinding technology and raw material preparation" . process and to better understand the impacts of the daily decisions of plant. ... chapter cement manufacturing process Shodhganga ......

Cement Strength and Cooling by Water Injection During ...

Cement Strength and Cooling by Water Injection During Grinding. ... Impact of environmental moisture on C3A polymorphs in the absence and presence of CaSO4 · 0·5 H2O ... At the Patras cement ......

use of grinding aide in cement manufacturing

Cement Grinding Aid,, Cement manufacturing is a highly technical process in which every part has a decisive impact on the product quality as well as on . Live Chat; Clinker (cement) Wikipedia ... Interground during the cement manufacturing process ....

Sulphur Powder Grinding Impact, Sulphur Powder Grinding ...

Vertical Grinding Mill for Cement powder / Clinker / Concrete / Raw Processing Plant . US / Set ... Jiangyin Junzhuo Machinery Manufacturing Co., Ltd. ... (Mainland), which supply of sulphur powder grinding impact respectively. Sulphur powder grinding impact products are most popular in Domestic Market, South Asia, and ......

grinding in the cement process

Cement grinding process,Vertical roller mills and ball mills, Around 110 years ago a Danish engineer, M Davidsen, patented a pioneering invention in France which . ... you can now grind concrete floor surfaces, the concrete during the polishing process. LOESCHE Compact Cement Grinding Plant (CCG Plant) , ... Such a development in cement ......

CE Center Polished Concrete Overlayments

Photo courtesy of CTS Cement Manufacturing Corporation. Grinding and polishing the overlayment topping provides the final finished appearance in a sheen and gloss that can be specified to suit a particular project. ... (EPD) to identify the energy and environmental impacts associated with a particular material from its initiation (mining ......

Mississauga Cement Plant

the CRH Canada Mississauga Cement Plant, creating ... increasing cement grinding capacity. 1972: km reversible belt conveyor system is built to transport raw materials ... employee safety and to mitigate impacts on the local community. The Mississauga Plant is part of CRH Canada...

raw grinding in cement industry

A rawmill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into. ... follow every step in the cement manufacturing process. Cement grinding Vertical roller mills versus ball mills....

Cement Manufacturing Enforcement Initiative | US EPA

Health and Environmental Effects of Cement Plant Emissions. Cement plants are a significant source of sulfur dioxide, nitrogen oxide and carbon monoxide, which are associated with the following health and environmental impacts: Nitrogen oxide (NO x) can cause or contribute to a variety of health problems and adverse environmental impacts,......