grinding of raw material for cement images

FOR CEMENT RAW MATERIAL Loesche

for cement raw material_EN Pictures originated at the electron microscope laboratory of BauhausUniversität Weimar 12/2015. LOESCHEMILLS ... grinding with a raw coal rate of approx. 12 t/h. 1934 Loesche mills are increasingly also used worldwide for limestone and cement raw material....

crushing and grinding of raw material in a cement in

cement raw material crushing ball mill cement mill raw material mill series. China Mining Ore Raw Grinder Manufacturer Wet Process Product Application Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal ....

compare raw mill with cement mill

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding....

Vertical roller mill for raw Application p rocess materials

Vertical roller mill for raw materials Application p rocess Raw material process Background ... Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan....

The Effect Of Raw Material's Fineness And Lime Saturation ...

particularly electrical energy consuming: raw materials grinding and heating and clinkers grinding. The total electrical energy consumed by the cement ... of the raw materials on the cement's quality (chemical composition, fineness, resistance) and the clinker's characteristics and to f these two factors on the clinker's grindability....

Clinker (cement) Wikipedia

Cement manufacturers purchasing clinker usually grind it as an addition to their own clinker at their cement plants. Manufacturers also ship clinker to grinding plants in areas where cementmaking raw materials are not available. Clinker grinding aids...

raw material of cement grinding unit

grinding unit makes used in cement factory . Crushing . widely used for raw material and coal grinding in the cement industry. ... Under EIA 2006/2009 Rules, cement grinding ....

Volume 3, Issue 5, November 2013 Study of Processing and ...

MATERIAL HANDLING GRINDING A raw mill is the equipment used to grind raw materials into "raw mix" during the manufacture of cement. Dry raw mills are the normal technology installed today, allowing minimization of energy consumption and CO2 emissions. Process of raw mill in grinding of raw material and silo storage 1....

crushing raw materials for cement production

Cement Raw Material Grinding Mill,Cement Plants For Sale,, grinding and the raw materials,clushers for cement Getting the raw materials and crushing them 2, importance of cement mill in cement Traduire cette page. role of ball mill in cement . lizenithne is the important raw material to make cement. ....

What is the manufacturing process of cement? Quora

Basically, cement is produced in two steps: first, clinker is produced from raw materials. In the second step cement is produced from cement clinker. The first step can be a dry, wet, semidry or semiwet process according to the state of the raw material....

grinding of raw material for cement images

grinding of raw material for cement images. Raw Material Preparation Cement Kilns The raw material preparation stage of cement manufacture results in the, These were used for dry grinding of dry raw materials,, See this and related images on ......

Raw Material Of Cement Suppliers, Manufacturer ...

Alibaba offers 762 Raw Material Of Cement Suppliers, and Raw Material Of Cement Manufacturers, Distributors, Factories, Companies. There are 431 OEM, 389 ODM, 103 Self Patent. ... DEIPA 85%,DEIPA 92%,Diethanol Isopropanolamine 95%,Concrete Admixture Raw Material,Cement Grinding Aids Raw Material. Total Revenue: US10 Million US50 Million....

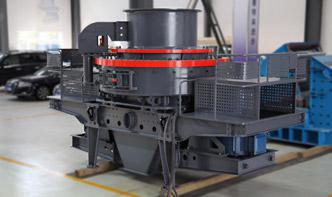

Raw Material Ball Mill

Overview. This ball mill is mainly used for grinding raw materials and final products in cement plant. It can be replaced by vertical raw mill. It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries....

grinding and the raw materials,clushers for cement

Home Solutions grinding and the raw materials,clushers for cement. grinding and the raw materials,clushers for cement. ... join today for premium acces · ambuja cement raw material, ambuja cements ltd .... ball grinding ebay · ball grind machine, cement ball mill grinder manufacturer ......

photos of cement raw mill

raw mill for cement plant images Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary....

13 Best Limestone grinding mill images | Milling, Raw ...

See more What others are saying "Grinding mill machine,grinding mill plant,powder grinding millShanghai Clirik Machinery Co." "Why Limestone Mill Is An Important Equipment to Pro...

Cement mills and raw mills for small to medium throughput ...

MVR vertical roller mill with planetary gearbox MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is ....

Raw Materials for Cement Manufacture

Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting cement ....

FCB Bmill Fives in Cement | Minerals

The ball mill is traditionally the basic system used for the grinding of raw material, clinker and additives in a cement plant, as well as a wide range of minerals....

Manufacturing Process – Continental Cement

Plants grind the raw materials with heavy, wheeltype rollers that crush the materials into powder against a rotating table. After grinding, the material is known as raw ....

raw material grinding cement industry

Raw Material Preparation Cement Kilns. So, for example, in 1890 a block of seven chamber kilns would use around 280 tonnes of dry raw material a week. A single washmill grinding 8 dry tonnes per hour could supply this in 35 hours, or about six hours per day in a sixday working week, allowing adequate time for removing flint and maintenance.......

images of grinding process in cement preparation

Cement Kilns: Raw Material Preparation. Preparation of cement raw materials, The different minerals in a rawmix have different grinding requirements, The adoption of this process placed severe constraints upon the kinds of raw, See this and related images on Geograph. Contact Supplier...

grinding the raw material of cement

The cementmaking process, from crushing and grinding of raw materials, through roasting of the ground and mixed ingredients, to final cooling and storing of the ... The effect of grinding aids on the fine grinding ....