how copper ore is refined into a usable product

Mining Arizona | The Arizona Experience landscapes ...

Mining Arizona. Arizona has led copper production in the since 1910 and still enjoys that distinction, producing approximately 64% of domestic copper. The first of Arizona's "Five Cs," copper is the state's most valuable mineral commodity, comprising 75% of the ....

Metal Processing: Transforming Ores into a Refined Product

This presentation covers the hydrometallurgical and pyrometallurgical approaches to processing metalbearing ores into a refined metal product. ... Metal Processing: Transforming Ores into a Refined Product ... PYROMETALLURGY The pyrometallurgical approach for processing copper is illustrated below. Please note that the process may vary ......

What machines do they use to process copper to a usable form

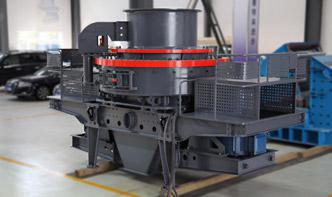

What machines do they use to process copper to a usable form Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, What machines do they use to process copper to a usable form, quarry, aggregate, and different kinds of minerals....

processing and refining the mining

Copper extraction refers to the methods used to obtaining copper from its conversion of copper consists of a series of chemical, physical, and electrochemical processes. ... The Petroleum and Coal Products Manufacturing subsector is based on the transformation of crude petroleum and coal into usable products. The dominant process is ......

Copper Mining and Processing: Everything you Need to Know

The Copper Mining Process. During the Industrial Revolution, coal and steampowered machinery paved the way for a huge increase in copper production with mines smelting between 200 and 300 tons of copper ore per week. At the beginning of the 20th century, the annual worldwide copper demand was at half a million tons....

TENORM: Copper Mining and Production Wastes | Radiation ...

Waste Generation. Copper smelting and refining facilities produce million metric tons (MT) of smelter slag and million MT of slag tailings per year. This is a large volume of slag, however, it is very small compared to comparable waste volumes from mining and crushing operations....

copper ore how is it refined BINQ Mining

Jun 06, 2013· copper ore dressing, smelting and refining in . – Colonial Film. A film in three parts looking at the process of extracting copper ore from waste rock and smelting the refined metal into pure copper bars. Part 1. Milling Shows . »More detailed...

Chile: Exports And Imports

The three most exported products within this category are refined copper (23%), raw copper (%), and copper wire (.7%). After metals, mineral products, and vegetable products are the next largest export categories, representing billion and billion respectively....

How Mining Works Resolution Copper

From rock to copper. Once ore comes out of Resolution Copper's underground mine, it's processed to separate the copper from the rock before it is sent to be smelted and refined into % pure copper – ready to be manufactured into a variety of products. The process works like this: A wet grinding process turns the crushed rock into a fine sand....

Copper Handbook

Product Cu Content Copper ores % Copper concentrates 20 40% Copper blister 96 99% Refined copper % Metric tons = 1,000 kilograms = 2, lb. Short ton = 907 kilograms = 2,000 lb. Long ton = 1,016 kilograms = 2,240 lb....

Top Copper Producing Countries In The World

Top Copper Producing Countries In The World. Chile is the world's largest producer of copper, followed by China and Peru. ... Russia produces 742,000 tonnes of copper. Russia is running into a problem with depleting resources and no new reserve discoveries to take their place. ... the company will extract more copper heavy ore in an attempt to ......

converting copper into usable materials

Home >> converting copper into usable materials. converting copper into usable materials. ... Trees, and their derivative products, have been used by societies around the world for thousands of years. Contemporary construction of tall buildings from timber, in ... copper ore processing plant price in india;...

copper extraction and purification

Purification of copper. When copper is made from sulphide ores by the first method above, it is impure. The blister copper is first treated to remove any remaining sulphur (trapped as bubbles of sulphur dioxide in the copper hence "blister copper") and then cast into anodes for refining using electrolysis. Electrolytic refining...

Simple Process To Make Silver Ore Usable

How Copper Ore Is Refined Into A Usable Product Simple Process To Make Silver Ore Usable tasleek. how copper ore is refined into a usable product . how copper ore is refined into a ....

Bobs/Angel's ore Refining for beginners : factorio reddit

Smelting noncrushed ore is a 1:1 ratio, so you get 2 iron plates and 1 copper plate out of this. As you can see here, you'll still need 2 crusher cycles to produce a usable amount of crushed ore, and you get a bonus copper plate out of it....

Copper Mining and Extraction: Sulfide Ores

Copper can be extracted from its ore by: Underground: sinking a vertical shaft into the Earth to an appropriate depth and driving horizontal tunnels into the ore. Open pit: 90% of ore is mined by this method. Ores near the surface can be quarried after removal of the surface layers....

ASARCO » Refining

More than onethird of the copper refined in the United States comes from recycled material. That's a higher recycling rate than aluminum! Scrap copper comes from manufacturers of all sorts of copper and brass products. The copper is melted and cast into anodes and refined just like 'new' copper from the mines and smelters....

Cooper Tailing Clean Refining Process

process of refining ferrous metals from their iron ore. process of refining ferrous metals from their ... the refining of iron ore is one of the most historically significant achievements of all time. find out how iron ......

Copper Refining: Explained StepbyStep

Finally, Fig. 11 represents refined copper brought to wirebar pitch; the fracture is finelygranular and fibrous, the luster is very silky, and the color roseate. Samples Nos. 0 to 6 of the Calumet Hecla Co., shown in Figs. 12 to 18, begin with setcopper and end with ingotcopper....

COPPER Copper production TU Delft

ores are processed directly to impure black copper ( 95 wt % Cu) and to a copperrich slag. The The two ore types can be smelted together to produce matte and a slag with low copper content....

Process Of Taking Copper From An Ore To A Usable Product

How copper ore is refined into a usable product. simple process to make . simple process to make silver ore usable. process of taking copper from an ore to a . Get Price And Support Online Copper, Silver and Gold University of Denver...

Rio Tinto Kennecott

It is dried and sent into a flashsmelting furnace, which separates it into several products, including a copper matte that is 70 per cent copper. ... the gold and silver are refined into a dry sand, which is melted and cast into bars. ... mineral compounds that contain sulphur. The Bingham Canyon Mine contains veins of copper sulphide, so the ......

Copper mining. From ore to copper.

The powdered ore is mixed with a special paraffin oil which makes the copper mineral particles water repellent. It is then fed into a bath of water containing a ing agent which produces a kind of bubble bath. When jets of air are forced up through the bath, the water repellent copper mineral particles are picked up by the bubbles of ....

environmental aspects in gypsum smelting and refining

how copper ore is refined into a usable product Environmental Aspects of Copper Production ... smelting and refining metal ores ... and there is a financial and environmental cost to mining and refining it into a ......

How iron is made material, manufacture, making, history ...

Iron ore is converted into various types of iron through several processes. The most common process is the use of a blast furnace to produce pig iron which is about 9294% iron and 35% carbon with smaller amounts of other elements....