limestone for manufacturing cement

High MgO in limestone International Cement Review

Apr 03, 2014· re High MgO in limestone. Hello Haliff, Above 2% in the clinker, MgO will appear as the mineral periclase. If the particle size of this periclase is large, this could result in an increase of the expansion of the cement, causing unsoundness....

Our Company | Central Plains CementCentral Plains Cement

Limestone Mining Cement manufacturing requires consistent and high quality sources of the four primary raw materials: calcium, aluminum, silica, and iron. Both facilities obtain the required calcium from limestone extracted from their own mines. Unusual for a cement plant, the Sugar Creek plant limestone source is an underground mine rather ......

USGS Minerals Information: Lime

Statistics and information on the worldwide supply, demand, and flow of lime. USGS Home Contact USGS Search USGS ... MI Home > Commodity > Lime. Lime Statistics and Information (For information on limestone, please see Crushed Stone or ... Lime Kiln Dust as a Potential Raw Material in Portland Cement Manufacturing OF Statistical ......

Some Engineering Properties of Limestone Concrete ...

The reduced cost of limestone is mainly due to energy savings by substitution of a portion of the calcined clinker with a small amount of limestone and to the presence of limestone deposits near cement kilns, and hence, reduced transportation costs....

Good Quality Of Limestone For Cement, Good Quality Of ...

Cement kiln is mainly used for calcining cement clinker, cement kiln include dry process production and wet process production. we are a comprehensive enterprise which integrates researching, manufacturing, market developing and service for mining crushing equipment....

Fine Limestone in Cement: Understanding Cement

Essential viewing for anyone with technical oversight of cement manufacturing, concrete mix design/production or concrete petrography There still seems to be some confusion about whether fine limestone in cement (up to about 5% as permitted by eg: US and European standards) is an inert filler, or whether it is chemically reactive and ......

What are some uses of limestone? Quora

Limestone is used as a raw material for cement, steel and limestone manufacturing, which is commercially important in a number of applications. Different limestone variants based on their application include chemical lime, industrial lime, fire resistant lime, and constructionbased limestone....

Lime Concrete Definition, Manufacturing and Properties ...

Since long, Lime has been used to make things like plaster and mortar. Lime is usually made by burning of ; lime itself is calcium oxide (CaO) and is made by roasting calcite Skip to main content ... Preparation and Properties of Lime Concrete. By: ... Manufacturing of lime....

Artistic Limestone

Manufacturing. Our company manufactures trim, mantels for interior and exterior homes. It can be done out of cement coating or limestone depending on the customers request. We provide oneonone service to ensue everyone's need and request are met. ... Artistic Limestone Shapes. Inquiries. Head Office. For any inquiries, questions or ......

Portland Limestone Cement | Materials That Perform ...

Performance and workability—with a lower carbon footprint. Our Portland Limestone Cement offers the same level of performance and workability you expect from standard Type I and Type II cements. But, because it's manufactured with quality limestone, it uses less clinker than the traditional manufacturing process and reduces CO 2 emissions by five to 10 percent per ton of cement....

CEMENT RAW MATERIALS British Geological Survey

limestone ( to tonnes) and tonnes of clay are quarried for each tonne of cement ... include carbon dioxide released during energy generation to power cement manufacturing plants. Worldwide it is thought that cement making is responsible for around 7% of total ... CEMENT RAW MATERIALS 2: Extraction and processing ....

Clinker (cement) Wikipedia

In the manufacture of Portland cement, clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter, produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stage....

(PDF) Cement Manufacturing ResearchGate

Cement manufacturing process ... constituents for cement (limestone and clay) are tak en from quarries in these areas (Hahn, . 1997)....

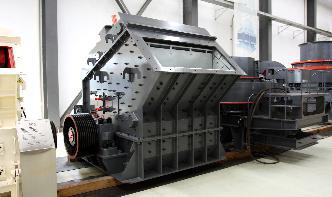

limestone crushing machine for cement production

raw material limestone for cement industry analysis of limestone raw material for 00 Limestone Quarry and Crushing Plant The major raw material for cement milling processing storage and handling. Get A Quote. List of manufacturing processes Wikipedia....

Cast Stone Manufacturing Process Corinthian Cast ...

Cast Stone is an excellent replacement for natural cut limestone, brownstone, sandstone, bluestone, granite, slate, marble and other natural building stones as well as terracotta. ... Manufacturing Cast Stone is generally regarded as the most laborintensive of all concrete products' manufacturing processes. There are several distinct ......

Mustknow: The cost elements of cement Yahoo Finance

Aug 18, 2014· Apart from limestone, other raw materials used in the cement industry are fly ash, slag, and gypsum. Transportation cost In the cement sector, the manufacturing ....

Manufacturing – Shun Shing Group

Shun Shing Group has a strong base of manufacturing projects in Bangladesh and plans to use this knowledge to expand into cement production in other countries. Shun Shing Group initially invested in a cement grinding mill located in Kaligonj, 38 km away from the capital city, Dhaka....

Cement Manufacturing Process: What is Cement made of.

Cement manufacturing process what is cement made of, it can be discussed conveniently under two headings: Selection of Raw materials and manufacturing methods. Raw Materials of Cement. Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method)....