milling and grinding operation

Hammer Milling and Jet Milling Fundamentals | AIChE

Select the optimal hammer mill or jet mill for your application by characterizing the feed material and conducting milling tests. Size reduction, or comminution, by mechanical crushing and grinding is an important unit operation in the chemical, power, mineral, metallurgical, and pharmaceutical industries....

CITY OF FARGO SPECIFICATIONS PAVEMENT MILLING OR .

CITY OF FARGO SPECIFICATIONS PAVEMENT MILLING OR GRINDING PART 1 DESCRIPTION OF WORK ... and disposal of all milling/grinding residue and the sweeping and cleaning of the existing and milled surfaces, and all other work as may be necessary to properly complete the pavement ... grinding operation. MILLING FULL WIDTH...

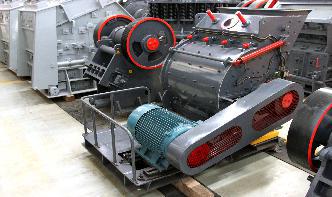

Size reduction, comminution grinding and milling of powders

A hammer mill is equipped with a simple rotating disc equipped with many pallets that are hitting the product and throwing it against the mill housing. A grinding sieve that will allow to enhance the milling process and reduce the Particle Size Distribution obtained can also be installed....

Grinding Milling | Mining | Dow Oil, Gas Mining

Effective grinding and milling of metal ores is essential in liberating and recovering valuable minerals. Energy consumed in the comminution process is a major cost in mineral processing operations. Grinding aids can be added to the wet milling process to improve grinding efficiency, help control ......

Mine operating costs and the potential impacts of energy ...

Mine operating costs and the potential impacts of energy and grinding. ... Milling: Power, grinding media and mill linings, consumables, reagents, equipment maintenance and repair, maintenance materials, milling specific labour, milling overheads ... Savings to milling operations will ultimately be limited by the particle size at which ......

Grinding Mills for Laboratory Gilson Co.

Grinding and milling products are used to process or test materials that are generally tough and fibrous, such as plastics, rubber and plant product not easily ....

How the Mill Works Operation of a Historic Grist Mill ...

How the Mill Works. It starts with the grain. Of course, grist mills grind a variety of grains, such as wheat, rye and corn. But in Rhode Island, particularly at Gray's Grist Mill, native grown corn, particularly Narragansett White Flint Corn, is the most common "grist for the mill."...

perform grinding operation pdf

milling operations Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal....

milling and grinding process

Asphalt Grinding and Removal Asphalt Grinding, Milling and Black Top Patching Full depth asphalt mill patching is a high production process designed to achieve . [Chat Online] mill grinding process ....

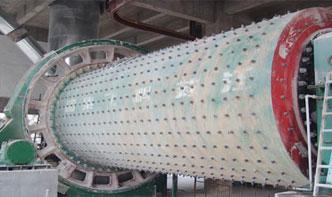

Grinding in Ball Mills: Modeling and Process Control

Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics....

Ultrasonic WetMilling and MicroGrinding Hielscher

Ultrasonic WetMilling and MicroGrinding. Ultrasonication is an efficient means for the wetmilling and microgrinding of particles. ... For the research and for the testing of this process as well as for many sonochemical processes we recommend our laboratory devices or the UIP1000hd....

Modern Methods of Milling | Shipton Mill Home of Organic ...

Modern Methods of Milling. ... Stone Grinding. The process of using stones to grind wheat into flour is an ancient tradition. The basic principle of a fixed "bed" stone and a rotating "runner" stone has changed very little in thousands of years. ... The secret is in the care of the stones, the setting of the stones during the milling ......

One Stop Milling, Drilling, Turning And Grinding : Modern ...

One Stop Milling, Drilling, Turning And Grinding Many shops, in an effort to reduce the handling of workpieces and get takt times (time spent in the cut) as low as possible, are looking to streamline this traditional hurryupandwait process scheme....

MACHINING OPERATIONS AND MACHINE TOOLS

MACHINING OPERATIONS AND MACHINE TOOLS. 1. Turning and Related Operations. 2. Drilling and Related Operations ... Milling • Milling – A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. (milling machine) ... Other Machining Operations • ....

The effect of grinding media J performance on milling and ...

The effect of grinding media performance on milling and operational behaviour The product quality like particle size in a crushing or dispersing process is defined by ......

nims surface grinding operation

nims cnc milling operation practice test Roadheader ... nims cnc milling operation practice test. ... NIMS Machining Level I Preparation Guide Grinding NEMES....

Grinding milling | WordReference Forums

Sep 15, 2009· Milling includes not only grinding, but other mechanical process transformations of material. This may involve pulverizing, melting and casting and rolling (think of steel mills, where ore is the raw material, and strip steel is one output.), stamping, embossing, and cutting....

Climb Milling versus Conventional Milling [ Sneaky CNC ...

Climb Milling versus Conventional Milling [ Sneaky CNC Tricks ] 5 () 6 votes . More articles you may like: [CNC Chef Video] Chip Thinning: Clear and Present Danger if Ignored; Solid Carbide End Mill Grades, Geometries, and Coatings [ FS Lesson 8 ]...

Quality Maryland Machine Shop: Milling, Lathe Work, Boring ...

Serving the Baltimore Metropolitan area for 30 years, Reco Machine, specializes in, milling, boring, grinding, lathe work, and welding. Our machine shop manufactures spare and new machine parts, as well as repair parts. ... By keeping, our operation relatively small we can pass on our low overhead costs to our customers. If you would enjoy ......

Grinding Mills for Sale Classifier Milling Systems

The Pin Mill . The pin mill is a very effective product that is at the top of our list of grinding mills for pin disc – or pulverizer – in a Classifier Milling Systems Pin Mill uses the internal circulation of material for producing fine grinds at high capacities....

WORKING PRINCIPLE AND TYPES OF MILLING MACHINE ...

Milling is basically known as most common type of machining process of removing the unwanted material from workpiece. Workpiece will be machined by inserting against one rotating cutter and rotating cutter will have a number of cutting sharp edges....

Turning milling drilling and grinding operations are ...

Turning, milling, drilling, and grinding operations are performed here. There are several conventional turning, milling, drilling and grinding machines, three CNC turning machines and one CNC jig boring machine. (See Appendix for detailed information about equipment in Conventional machining area) Operations Turning is one of the basic machining processes; it is the ......

Types of milling machine mech4study

In this article we will learn about types of milling machine based on their design, uses etc. ... These machines are the modern milling machines which are developed to easy the milling operations according to the jobs. ... Grinding Machining Process : Complete Notes mech4study....

Grinding Milling Powder ProcessSolutions

Grinding and Milling Powder processing often involves bulk powders, additives, or ingredients being milled for particle size reduction. A mill or grinder uses a mechanical action to break the material and reduce it to the required size....