mining ore processing plant added value

Min. Mining ESDM 07/2012 Increasing of mineral value added ...

14. Processing and purifying are mining business activities to improve the quality of mineral and to use and obtain byproduct mineral. 15. Value added is the added of minerals value as a result of a process performed on the mineral. 16. Increase in value added is the increase in the value of minerals to produce economic, social and cultural ......

OVERVIEW OF PGM PROCESSING

Options Available in the PGM Processing Value Chain. The value chain can be configured to suit the available capital as long there is suitably economic capacity ... it's not straight forward Earliest logical exit is after concentrating to sell PGM concentrate, but options are limited.. Mining Concentrator Smelting Converting Base Metal Refining...

Iron Ore Smelting Process Brighthub Engineering

Introduction to Iron Ore and Steel Smelting Processing. Iron ore is obtained in the conventional method of open cast or underground mining and conveying the ore to the surface preparation are where it is crushed, washed, and transported to the smelter. ... At the surface iron ore processing plants, the iron ore is put through crushers and ball ......

Mining Statistics Facts | Statista

Mining Statistics Facts ... In terms of volume, the most exploited commodities worldwide are coal, iron ore, bauxite, and potash. ... Value added by the mining industry ;...

Sampling practice and theory Mine

Tha values of k are the constant derrived for differing ore bodies, in this example gold. The values of "n" are a probability factor that attempts to associate the probability that any grain is the grain of value, in this case gold. The values of "d" are the diameter of the largest particle of ore to be sampled....

MINING Make In India

This turnaround is very much visible in terms of growth in Gross Value Added (GVA) in mining and quarrying sector. The sector grew by % and % in 201617 and 201718 respectively. The Index of Industrial Production of mining registered growth of percent during 201718. There is a noticeable surge in mineral production in India....

Iron Ore Mining News and Commentary |

Iron Ore mining news. Explore related Iron Ore articles for more information on the Iron Ore mining industry....

Cobalt Mining Legacy

Ore Processing. In this mixture minerals in the ore collide with air bubbles. Some minerals favour contact with the air, and will attach to air bubbles and float to the surface of the flotation cell. As air bubbles accumulate at the surface a froth forms and eventually overflows as the ore concentrate....

Lithium Mining processing value added products information

Chile, China and the United States are the world's leading producers of lithium ore and brine. Other significant producers include Argentina, Brazil, Australia, Portugal,Russia and Zimbabwe....

The nickel laterite challenge Australian Mining

The nickel laterite challenge. Companies are increasingly looking to derive nickel production from nickel laterites. Whilst these near surface ores are relatively attractive from a mining perspective they are generally mineralogically complex and lower in nickel (and cobalt) grade presenting issues associated with developing economically attractive processing options....

The Added Value of Process Mining | BPTrends

KPIs and outsourcing. Process mining can be used for a first assessment of the process. The processoriented analysis helps to understand how the process works in detail, and which KPIs should be measured, and where exactly the measure points should be placed to control and monitor the process on a longterm basis....

Iron Ore Smelting Process Brighthub Engineering

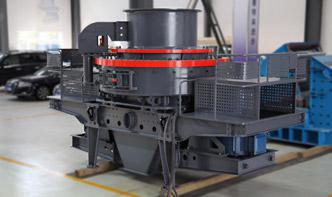

There are two distinct categories of iron ore mining, surface mining such as open cast or strip mining and underground mining. At the surface iron ore processing plants, the iron ore is put through crushers and ball mills to break it into a uniform and more workable size ....

OPP: Ore Preparation Plants Explained | Oil Sands Magazine

The Ore Preparation Plant (OPP) is the first step within any Bitumen Production facility where mined oil sands is loosely crushed and mixed with hot/warm water to form a slurry that can be pumped to the main processing plant....

Diamond Mining Methods | Diamond Museum Cape Town

PROCESSING OF ORE TO EXTRACT ROUGH DIAMONDS. Stage 3 – Cyclonic separation plant During this stage the diamond bearing ore is mixed with a solution of ferrosilicon powder and water, which is measured to a specific relative density. This solution is fed into a cyclone, which tumbles the material and forces a separation....

Mineral Processing Hatch

Dewatering. Dewatering and solid–liquid separation is an important part of any mineral processing plant. It spans a range of stages, from feed preparation to concentrate handling and tailings disposal. Our experience in this area is extensive, and includes thickener and filter technologies from testing to specification and control....

Management of radiation hazards from mining of mineral ...

The management of radiation hazards from the mining of mineral ... processing plant, which involves the processing of monazite at Pinjarra 2 and ... with particular reference to the establishment of "value added" secondary processing industries in close proximity to regional centres. Finally, the matrix of Commonwealth and State...

ABB in Mining Mineral

ABB in Mining Mineral Processing From Mine to Market Power Circuit Breakers, Relays, Disconnect Switches Ore Pocket Weighing ... our approach covers the complete valueadded chain, from your mine to the product you market. We excel at merging equipment, skills, and services to develop a ... Mines and processing plants need integrated process ......

Copper Mining and Processing: Processing of Copper Ores ...

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of % pure copper called cathodes, which will ultimately be made into products for everyday use....

Mining for Bitumen | Oil Sands Magazine

Ore Preparation: Hot/warm water is added to the oil sands producing a slurry that can be pumped to the processing plant. ... OIL SANDS MINING PIT. ... clarified water is recycled back to the processing plant for use as process water....

Govt to set up lithium plant | The Herald

Govt to set up lithium plant. "Therefore the Government is planning to set up a processing plant that will add value to the mineral. "So if we are to go into production of what we call lithium battery we could produce lithium carbonate which costs 5 000 per tonne as opposed to the 180 per tonne and this can be produced in Zimbabwe," he said....

Diamond Processing Flow Chart of Beneficiation

Diamond Processing Flow Chart #3. With variations it can be used to process 100 to 500 tons per hour of Kimberlite ore and is also arranged to handle weathered or soft ores. For the hard ore as mined the flowsheet follows conventional methods of stage crushing and screening to reduce the ore to —½"....