objectives of making a grinding mill

Horizontal and Vertical Millstone . High quality. Buy here.

ENGSKO Millstones. The most essential part of the mill is the millstone, which is perfect for grinding of healthy, organic wholemeal flour. The quality of the millstone is decisive both for the grinding capacity of the mill and the quality of the ground product....

Powder Grinding Production Line Wholesale, Line Suppliers ...

Not only can the HC1700 grinding mill live up to the national industrial policy and meet the needs of mass production, but also fills the gap of largesize mill in the mill industry. This kind of mill plays a leading role in grinding technology, production capacity and power consumption per ton....

The Corona Mill and Tortillas | The Fresh Loaf

Aug 02, 2010· The Corona Mill and Tortillas. Tortillas made from fresh masa taste and smell much better than ones made from dried masa harina, which in turn are much better than storebought corn tortillas. I've since made great peanut butter with my Corona, and expect that I can do fromscratch falafels by grinding soaked chickpeas....

Choosing the Best Media Mill For Your Wet Grinding Application

The massspecific energy is the work required to mill a quantity of product to a desired grinding specification. Massspecific energy can be relayed in a variety of engineering units such as: Kilowatt hours per pound, Kilowatt hours per kilogram, Kilowatt hours per ....

Metallurgist Mineral Processing Engineer

911 Metallurgist and mineral processing engineers offer execution and implementation services (crushing flotation, grinding) to the world of mining and metallurgy....

My Adventures In Brewing: Make your own grain mill for !

Jun 29, 2009· Make your own grain mill for ! Okay, so now that my first "homemalted" brewing attempt was a complete failure, I have assessed my procedures and have come to the conclusion that poorly milled grain was the culprit....

Milling and processing IRRI Rice Knowledge Bank

To improve the quality of the rice, factors such as the paddy quality and milling technology should be considered. To obtain good paddy quality: Mill at the right moisture content (MC) A moisture content of 14% MC is ideal for milling....

Goals Objectives for a Plant Operations Director |

Since the principle objective of any business is profit, much of the operations director's focus is on running the plant more efficiently to improve the company's chances of profitability. Making more product in the same time frame, or with fewer staff, reduces the cost of manufacturing....

Economics of Grinding for Pelleted Feeds original

Grinding equipment. Both roller mills and hammermills have been applied to the task of particle size reduction or grinding in feed milling applications. Hammermills have traditionally been used to produce the finer grinds commonly used for pelleting and for many mash (meal or ....

Choosing a Grain Mill Flour Mill | Everything Kitchens

The Wonder Mill Grain Mill has no option for manual operation, and can only grind 12 cups at once. This unit has stainlesssteel grinding blades and a selfcleaning milling chamber. We recommend this one for people with respiratory problems, as this unit leaves less flour dust in the air than most other electric mills....

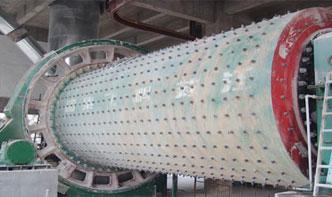

How are the number of balls in ball mill grinding for ...

How are the number of balls in ball mill grinding for grinding fly ash particles selected? ... able to make an objective function for me to optimize the performance ... fineness caused in the ball ......

Gearless mill drives Grinding | ABB

Gearless mill drive system. Maximum availability and productivity Go gearless to meet your business objetives by exceeding standard availability targets in your grinding operations. ABB's GMD is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous......

Manual Mill Basics 201

Manual Mill Basics 201. This class introduces the machine components, cutting tools and workholding devices commonly used on milling machines. The class also provides an overview of the various controls on the mill that are used to adjust spindle rotation, speed, feed, and ....

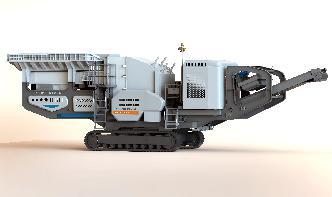

National Rail Plan cost of complete track crushing ...

Grinding Mill. Detail Ore Beneficiation. Detail Washing Screening. Detail Ore Beneficiation. Detail More>> LATEST CASES. 500tph stone crushing plant in Georgia. Material : Metal ore and nonmetallic minerals. Equipment : Jaw Crusher,Cone Crusher,Vibrating Screen. More. Highway construction mobile crushing plant in Qatar ......

Grinding at the mill | News, Sports, Jobs The Intermountain

In Genesis 18:6, a hand mill was used by Sarah at Abraham's request to make ready three measures of fine meal. In Judges 9:53 and 2nd 11:21, it was with the upper stone or a millstone "rider," or the "runner," the stone which revolves, of a hand mill, that "a certain woman" at Thebez used to break Abimelech's skull....

Mill | Definition of Mill by MerriamWebster

Definition of mill for English Language Learners. : to produce (something) in a mill especially by grinding, crushing, or cutting it. of a group of people : to walk around in a ....

Food Grinding And Pulverizer Machines ManufacturerHigao Tech

glossy ganoderma grinding mill machine. two stage colloid mill for wet materials grinding. spices grinding machine. ... food and medicine granulator machine for making granules and particles and pellets; food and feed additives granulating machine to make granules;...

Process Of Preparing Ganoderma Grinding Powder Crusher Mills

Coffee preparation – Wikipedia, the free encyclopedia. There are four methods of grinding coffee for . The main difference is that the coffee beans are ground ....

Feed Milling Grinding Equipment Feed Grain Buyers Guide

Omas Galileo Plansifter. Central supporting framework made of fabricated sheet steel, hanging by means of flexible canes,complete with drive shaft and counter weight supported by two oscillating double row ....

Modern Processing Techniques to minimize cost in Cement ...

Typically, the motor of the ball mill consumes about 14 15 kWh/ ton of raw mix whereas the VRM motor uses 7 8 kWh/ ton. On an overall basis, VRM consumes about 20 % lower specific energy than conventional closed circuit ball mills and is being widely used for ....

Grain mill | structure for grinding cereals |

Grain mill. Modern mills employ pairs of steel cylinders instead of wheels. For grinding into flour, wheat is ground between a series of cylinders, beginning with a set of grooved cylinders to break the grain open and ending with a final set of smooth cylinders to reduce the coarse meal to fine flour....

Mill Grinding at Thomas Scientific

Mixer Mill MM 200. .With its high performance and great flexibility the mixer mill MM 200 is a unique product in the market. Product Advantages reproducible, efficient grinding, mixing and homogenization in seconds powerful grinding by impact and friction, up to 25 Hz for up to 20 samples per.....