process iron ore mining

Iron Ore Smelting Process Brighthub Engineering

Iron Ore Smelting Process Using Modern Blast Furnaces. The furnace has a more efficient shape to suit automation, with the contents of iron ore, limestone and coke being carefully measured, conveyed and loaded into the furnace from the top through specially designed gastight valves. High temperature air ....

iron ore mining process

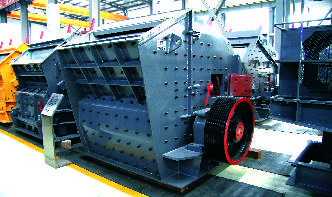

Iron ore mining process and iron ore mining equipments SBM Mining and processing of iron ore involves coarse crushing and screening. Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening....

(PDF) Life cycle assessment of iron ore mining and processing

Life cycle assessment of iron ore mining and processing. Mining of iron ore is a highly capital and energyintensive process. Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study. The environmental impacts considered in......

mining process of iron ore

Iron Ore,Production Process of Iron Ore,Iron HOT MINING Ore, which contains an economical use of iron, is called an iron ore. There are many types of iron ore, magnetite (Fe3O4), hematite (Fe2O3) and (FeCO3), etc, which are mainly used for iron making....

process of smelting iron ore | Solution for ore mining

Iron state of the compounds exist in nature, especially in particular iron oxide. In theory, any ore containing iron or iron compounds called iron ore; blast furnace . Smelting of Iron Ore information on smelting. Thus, the iron ore must be powdered and mixed with coke, to be burnt in the smelting process....

Planning an Iron Ore Mine: From Exploration Data to ...

Figure 1: Iron ore mining in Western Australia Current production from Western Australia is approximately 470 million tonnes a year, typically at about 60% iron content. There are plans to double this production rate by 2020 (Geoscience Australia, 2012)....

process or mining iron ore Mineral Processing EPC

process or mining iron ore offers 347 iron ore concentrate price products. About 60% of these are mineral separator, 23% are iron ore, and 2% are other mining machines. . iron ore concentrate, iron ore concentrate price of hematite separation process....

mining of iron and ore process

Iron ore mining process and iron ore mining equipments SBM Mining and processing of iron ore involves coarse crushing and screening. Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening....

Magnetite Ore, Magnetite Iron Ore, Iron Ore Mining Process

Magnetite ore (Fe3O4) is a ferromagnetic mineral commonly used in magnetic separation coal washing processes.. Coal washing using magnetite is used to remove contamination from runofmine (ROM) coal, which usually contains rocks, middlings, used consumables and other contamination introduced by the mining process....

Iron Ore Prices Surge Over Supply Concerns After Vale ...

Ironore futures climbed following a dam failure at one of Vale's Brazilian mines that killed at least 60 people, less than four years after the failure of a dam jointly owned by Vale and BHP ......

Vale opens largest iron ore mine in its history |

Vale opens largest iron ore mine in its history. The project was named after its location: it is on block D of the S11 ore body, which contains four blocks: A, B, C and D. According to Vale, S11's mineral potential is 10 billion tons of iron ore, and blocks C and D together have reserves of billion metric tons. The first geological surveys in the region occurred in the 1970's....

Iron ore mining in Western Australia Wikipedia

Iron ore mining in Western Australia. The bulk of Western Australian ore went to China, which imported 70 percent of 2010 production, followed by Japan with 19% and South Korea with 10%. The state has the world's largest Economic Demonstrated Resources of iron ore with 22% of the world's iron ore followed by Brazil with 17%, Russia with 15% and China with 14%....

New dry iron ore processing technology ... Australian Mining

New dry iron ore processing technology developed. The method does not use water to process iron ore, instead it transforms mining tailings – with low iron content and no commercial value – into high iron content and low contaminants, making it economically viable. As iron ore must be composed of grades of at least 58 per cent,......

the process of iron ore mining Mineral Processing EPC

the process of iron ore mining offers 347 iron ore concentrate price products. About 60% of these are mineral separator, 23% are iron ore, and 2% are other mining machines. . iron ore concentrate, iron ore concentrate price of hematite separation process....

Iron Mining Process Minnesota Iron

The iron ore is separated from the taconite using magnetism. The remaining rock is waste material and is dumped into tailings basins. The taconite powder with the iron in it is called concentrate. Pellets The concentrate (the wet taconite powder) is rolled with clay inside large rotating cylinders....

process of smelting iron ore | Solution for ore mining

smelting process of iron ore information Smelting of Iron Ore information on smelting Thus, the iron ore must be powdered and mixed with coke, to be burnt in the smelting process. ... iron ore smelting Smelting Wikipedia, the free encyclopedia Smelting is a form of extractive metallurgy ; its main use is to produce a metal from its ore. ......

gold mining operations in south africa iron ore mining process

The Mining Process Waihi Gold. Mining open pit and underground To define the ore from the waste rock, samples are taken and assayed. Assay results are used to mark out areas of ore and waste rock, which are mined separately....

Understanding Iron Ores and Mining of Iron Ore |

Understanding Iron Ores and Mining of Iron Ore. Iron (Fe) is an abundant and a widely distributed element in the in the crust of the earth, constituting on an average ranging from 2 % to 3 % in sedimentary rocks to % in basalt and gabbro. Its supply is ....

Iron Ore and Pellets

Iron ore is found in nature in the form of rocks, mixed with other elements. By means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies. The iron ore produced by Vale can be found in houses, cars and appliances....

process iron ore mining

Iron Ore Mining Techniques, Metal Extraction, Types of Iron Ores ... Iron ores are rocks and mineral deposits from which clanging iron can be reasonably ... The smelting process allows the iron ore to be heated with carbon....

Iron Ore Beneficiation Process

Iron Ore Beneficiation Process View Larger Image During the last ten years great strides have been made, on the Mesabi range, in the practice of beneficiating low grade iron ore material....

(PDF) Iron Ore Sintering: Process ResearchGate

Iron Ore Sintering: Process. Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming agents and solid fuel (coke). The purpose of the sintering process is manufacturing a product with ....

USGS Minerals Information: Iron Ore

Iron Ore Statistics and Information. Iron ore is the source of primary iron for the world's iron and steel industries. It is therefore essential for the production of steel, which in turn is essential to maintain a strong industrial base. Almost all (98%) iron ore is used in steelmaking. Iron ore is ....