process of cement making

Improve Of Cement Making Process

improve of cement making process (price of petrol increase / the cement making process... Thanks in advance for your help I need the help of review my essay in grammar,vocabulary and sentence,or ......

Cement making process

Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients....

Process of Making Cement | TutorVista

Process of Making Cement Introduction to process of making cement: Cement is a fine grey powdery substance made from limestone and clay which, after mixing with water, sets to hard mass....

Cement Manufacturers, Cement Manufacturing Process, Making ...

Cement Manufacturing Process JK Lakshmi Cement, a member of the prestigious Organisation, is a blue chip company with an annual turnover of over Rs. 2300 crores (Rs. 23 billion). Launched in 1982, JK Lakshmi Cement (Sirohi Plant), an ISO 9001:2008 14001:2004 company, is built over an area of about 8 square kilometers, amongst the lush ......

Making concrete Learn Chemistry

Concrete, cement and mortar surrounds us. Cement, an ultrafine grey powder, binds sand and rocks into a mass or matrix of concrete. Making concrete is similar in principle to baking a cake: selected ingredients are mixed together, heated, and allowed to set....

What are methods for making concrete? Quora

The process of making concrete depends on strength of hardened concrete you need. In general terms the raw materials are mixed in a definite ratio according to their volumes. The procedure is as follows: 1. Say take a ratio 1::3 for cement, sand (fine aggregate) and ....

Emissions from the Cement Industry

The direct emissions of cement occur through a chemical process called calcination. Calcination occurs when limestone, which is made of calcium carbonate, is heated, breaking down into calcium oxide and CO2. This process accounts for ~50 percent of all emissions from cement production....

How to Make Concrete Blocks DIY MOTHER EARTH NEWS

How to Make Concrete Blocks. Learn how Hi Sibley produces 100 concrete blocks per hour as he describes the concrete block manufacturing process. Next, crane is attached to mold and the ejector swung into position. Holding the ejector down, operator depresses a pedal, lifting the mold....

How concrete is made material, manufacture, making, how ...

The first step in making concrete is to prepare the cement. One type of cement, Pordand cement, is considered superior to natural cement because it is stronger, more ....

CO2 Cement Production IPCC

Carbon dioxide (CO2) is a by product of a chemical conversion process used in the production of clinker, a component of cement, in which limestone (CaCO3) is converted to lime (CaO). CO2 is also emitted during cement production by fossil fuel combustion and is accounted for elsewhere....

Cement Manufacturing Process: What is Cement made of.

Methods of Manufacturing Process of Cement. At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process. The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry state. ..and,......

Manufacturing process | Lafarge Cement, concrete ...

Step 1: Mining. The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km....

Manufacture of Portland cement

The cements of interest in the making of concrete have the property of setting and hardening under water by virtue of a chemical reaction with it and are, therefore, called hydraulic cement. ... Methods of cement manufacturing 1 Wet process ___ grinding and ....

cement making process

cement making process The process of making cement is a continuous or semi continuous process. It is made up of some steps; which starts from the raw material extraction to the production and delivery....

Energy Efficiency and Saving in the Cement Industry ...

Portland cement, the most widely used cement type, contains 95% cement clinker. Large amounts of electricity are used grinding the raw materials and finished cement. The clinkermaking process also emits CO 2 as a byproduct during the calcination of limestone....

How Cement Tiles are Made (Video) | Villa Lagoon Tile

Concrete is a mixture of cement, aggregate (sand, gravel, etc), and water. Cement tiles may use more precisely controlled ingredients than structural concrete, but the basic process is the same. Cement cures and hardens chemically over time....

Understanding How The Indian Cement Industry Works

Cement Industry in India. Most power producers want to dispose of flyash and one of the ways is by selling it to cement manufacturers who can substitute it for limestone in the cement making process. Similarly slag is a byproduct of Steel making process and is often sold to cement makers as a substitute for limestone in the cement making process....

Process for Making Concrete Ciment Québec

Process for Making Concrete. Concrete is comprised of different sizes of aggregate, sand, admixtures, water, and Portland cement. These raw materials are stored in silos or tanks on the site of the concrete ....

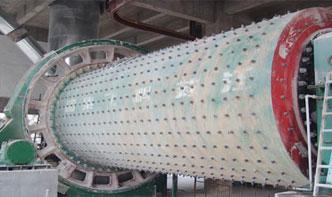

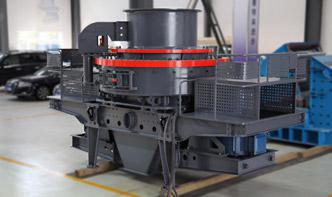

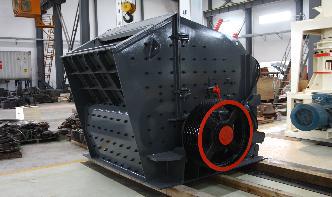

Cement Making Machine, Cement Making Machine ... Alibaba

Application of Cement Making Machine : The Cement Making Machine is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. 3) The kiln head adopts housing type sealing and kiln rear uses axial contact sealing unit so ....

Cement Extraction and processing |

Manufacture of cement. The three processes of manufacture are known as the wet, dry, and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry, ground dry and fed as a dry powder, or ground dry and then moistened to ....

process of making orient cement

process of making cement IELTS Task 1 Process Cement and Concrete . 14/4/2015 · Below is a sample band 9 answer to a process task 1 question on concrete production. Source: Cambridge English IELTS Past Papers....

How to Make Portland Cement Civil Engineers Forum

Apr 18, 2018· How to Make Portland Cement: The Full Manufacturing Process Portland cement is the most common type of cement. In particular, "Ordinary Portland cement" is the normal, grey cement with which most people are familiar....

The Making of Cement Malabar Cements Ltd

The Making of Cement MCL manufactures cement through the most modern dry process method based on worldrenowned German technology. The major raw materials for cement manufacture are limestone and laterite, which are natural minerals obtained within the state....

Concrete Mold Making Casting with SmoothOn Materials

Concrete Mold Making Casting Concrete casting pros from around the world know SmoothOn liquid rubber products as the industry standard for making rubber molds that have the abrasion resistance and tear strength needed to keep production moving....

cement making process diagram BINQ Mining

Schenck Process CEMENT PROCESSING SYSTEM Below is a diagram of the cement manufacturing process. Colored equipment indicates . Colored equipment indicates . » More detailed...