processes of cone crushers

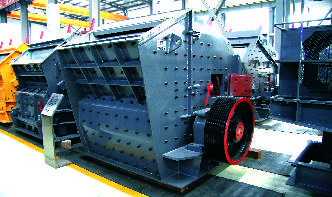

Cone crushers Mining Machinery

The Main Types and Function of Cone Crushers: This series of crusher machine is divided into three types, namely coarse cone crusher, medium cone crusher and fine cone crusher, and the standard type is suitable for medium crushing; the medium type and the shortheaded type is suitable for fine crushing, so that the customers can choose different types according specific need....

working process of cone crusher

the first mp2500 cone crusher to be in zambia early 2015 Zambian, Apr 16, 2015, One result of this work, the world's largest cone crushers, the MP2500,, The MP2500 was selected for Sentinel because it can process large....

leaching process kyc cone crushing plant

Hydraulic cone crusher is a new generation of product which takes the place of spring cone crusher, which is also the ideal equipment of large sand making plant and quarry plant. The hydraulic cone crusher produced by Joyal Machinery is widely used in mine, cement, sand, chemical industry and so on, which is the pillar equipment of mining . Get ......

Cone Crusher Process Design Of Ajaokuta Steel | Crusher ...

Cone crusher,Rock cone crusher,Cone crushers,CS cone . The design process of cone crusher has always been . The uncrushed materials such as steel can cause great damage and more cost to the crusher when getting into ....

mobile cone crusher process

ensp·enspMobile cone crusher is a flexible mobile crushing plant, designed for efficient secondary and fine crushing and screening appliions, high capacity cone crushers (CS75, HP160, HP220), feeders and screens, enabling it to process practically any rock or ore....

Process Plant: Bolt On Application Specialist : Cone ...

A Process Plant: Bolt On Application Specialist : Cone Crushers job brought to you on the Jobs4Mining website. Jobs 4 mining, home for mine vacancies, coal geologist, mining engineers, geosciences, mining jobs, mineral extraction, mining news, mining recruitment, geologist employment, mining jobs australia, mine operation yemen...

Crushers Products Group

Maximum efficiency in extreme crushing conditions. We deliver tough and reliable crushers that are designed to handle a wide range of crushing applications from primary, secondary, and tertiary hard rock crushing to mixed demolition debris, crushed or broken concrete and asphalt, sand, gravel and quarried stone. Available in stationary......

working process of cone crusher

US440E mobile cone crusher is a highly efficient electrically powered, trackmounted complete process machine with a cone crusher and screen onboard. It has been designed to meet the demands of quarry operators, construction companies, mining companies or contractors working with highly abrasive materials, and it is the ideal solution for your secondary and tertiary applications....

What are crushing process of cone crusher in gravel ...

The whole gravel crushing plant is consisted of 2 sets PE 500 x 750 jaw crusher,2 sets CZS36B cone crusher,2 sets GZD850 x 3000 vibrating feeder and 2 sets 3YZS1548 vibrating screen. What are crushing process of cone crusher in gravel crushing plant?...

cone crushers secondary

Processes for Beneficiation of Iron Ores Iron is an abundant element in the earths crust averaging from 2 % to 3 % in sedimentary rocks to % in basalt and gabbro. Read More; Aggregate Designs Corporation Cone Crusher Information. Cone Crushers an Introduction. This section of the Aggregate Designs Corporation web site is intended to inform ......

Cone Crusher | Working Principle | Animation | Engineering ...

Cone Crusher. Only one time breaking is carryout of larger pieces of rocks from ore. Broken pieces of rocks fall down to the next position where it is broken again. Same process continues until the broken pieces become small enough so that it can pass through ....

Maximising productivity from secondary cone crushers

A secondary cone crusher will need to handle peak power permissible by the drive motor. A secondary cone crusher should be matched to a drive motor designed and specified for high load crushing duty. The motor specifications for top performing cone crushers are with a Service Factor and a 200% breakdown torque....

working process of cone crusher

working proces of cone crushing plant, working of worm gear working process of the coal mining and crushing plants . working process of the coal mining and » Learn More And cone crusher is the core crushing equipment....

process of removing cone crusher

The wheel mobile cone crusher is commonly used portable rock crusher, which can ... cobbles and construction waste produced during the city relozation process. ... the hydraulic pressure to remove the obstacles of the portable rock crusher....

What is a Cone Crusher? (with picture)

Mar 12, 2019· A cone crusher is capable of breaking rocks into smaller pieces. Most cone crushers are a middle step in the crushing process, receiving rocks that have been broken down by machines that specifically handle larger rocks. Most crushers handle only ....

cone crushers

the process until the best possible product is safely delivered to you — and performing. Provides: • Engineering in 3D ... cone crushers for consistent performance. The experience shows in today's comprehensive line of SBS cone crushers....

Cone Crushers Manufacturers Suppliers in India | Cone ...

Cone Crusher Machine BuildMate cone crushers feature a unique combination of cavity design, speed and throw which provides higher capacity and superior product quality in wide range of applications. ... "Buildmate commissioned AAC plants at our factory which have advanced technology processes resulting in high quality ACC blocks." ......

crusher cone process crusher

Gyratory Crusher Process. Used Cone crushers. There are several choices in buying a used cone crusher: Buying just the bare cone crusher Buying the cone crusher already on a frame Buying a portable cone crusher . Chat Online. Superpave Gyratory Compactor HM451. The Superpave Gyratory Compactor by James Cox and Sons . Get Price...

coal crushing process YouTube

Oct 10, 2012· Coal jaw crusher for primary crushing process,suppliers,for sale ... Coal Crushing Process. As we all know, coal is a very useful resource in human consumption....

's Crushing and screening solutions InfoMine

This is guaran teed by the optimal combination of operat ing speed, crushing chamber design and setting. High rotor inertia produces excep tionally high capacities. The heavy duty structure of the crusher frame, breaker plates, shaft and bearings allows for the use of very small settings (css)....

Cone Crushers |

Cone Crushers Safety, Productivity Ease of Maintenance. manufactures a wide range of crushing equipment that's engineered with the highest standards of safety, productivity, and ease of maintenance for mining, aggregates, crushed stone production, and recycling applications....

UH640 Mobile cone crusher — Mining and Rock .

UH640 Mobile cone crusher. With UH640 you will also benefit from a dual interlocking and intelligence system that is integrated with ASRi (automatic setting regulation system) which gives you optimal performance and minimal downtime. With the vast choice of different mantles and settings, UH640 is ideal for a wide range of applications....

Cone crushers Mining Machinery

Cone crushers are widely used in the secondary, fine and ultrafine crushing processes, researched and developed by adopting the world's most advanced crushing technology, integrating mechanics, hydraulics, electric, intelligent control and other technologies together....

cone crusher processes

processes of cone crushers processes of cone crushers. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals....