processing of iron ores

Froth Flotation of Iron Ores sapub

With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market....

iron ore processing and beneficiation

Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron. magnetite)....

Iron Ore Pelletization Packing Machines | Electrostatic ...

The process of pelletization enables converting Iron Ore Fines into "Uniformed Sized Iron Ore Pellets" that can be charged into the blast furnaces or for Production of Direct Reduced Iron (DRI). Pellets are uniform size, with purity of 63% 65% contributing to faster reduction and ....

process of iron ore separation

Iron ore dry separation equipment is iron ore dry separation equipment researched high intensity magnetic separation of hematite ore, recovering magnetite by separation and other mineral processing methods, ore powder adopts the...

Calculating The Value Of Iron Ores In Ironmaking And ...

Table 1. Head chemistries and ultrafines content of iron ores (weight % on dry basis). It has been assumed that the ferrous burden comprises 70% sinter, 20% lump ore and 10% pellets, with 10% of the sinter fines blend made up with Marra Mamba ore in the reference case....

Iron ore mining Schenck Process

Iron ore mining Working with Iron Ore industry to improve recovery. Schenck Process has been active in iron ore mining for more than 20 years by providing its special separation and vibrating solutions to enhance the iron ore recovery rate....

Iron Ore Mining Artifacts

Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel. 98% of the mined iron ore is used to make steel. Minnesota's iron ore was actually discovered while prospectors were searching for gold....

Vale opens largest iron ore mine in its history |

Vale opens largest iron ore mine in its history. The project was named after its location: it is on block D of the S11 ore body, which contains four blocks: A, B, C and D. According to Vale, S11's mineral potential is 10 billion tons of iron ore, and blocks C and D together have reserves of billion metric tons. The first geological surveys in the region occurred in the 1970's....

Iron Ore Mining Techniques, Metal Extraction, Types of ...

Iron ores are rocks and mineral deposits from which clanging iron can be reasonably extracted. The ores are generally prosperous in iron oxides and fluctuate in color ranging from dark grey, bright yellow, deep purple, to even rusty red. The iron by its own is usually found in the structure of magnetite (Fe3O4), hematite (Fe2O3), goethite,......

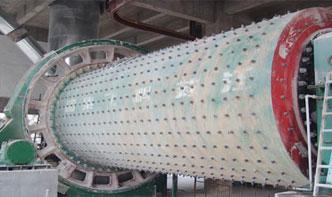

Processing of Magnetite Iron Ores Comparing Grinding ...

Processing of Magnetite Iron Ores Comparing Grinding Options Although the majority of current steel production is supported by iron ore sourced from high grade haemetite deposits, the longterm growing demand for steel has led to higher raw material prices and opened the way for many new magnetite deposits to also be developed....

Taconite Ore Processing US EPA

2/97 Taconite Ore Processing Crude ores in which most of the recoverable iron is magnetite (or, in rare cases, maghemite) are normally concentrated by magnetic separation....

Introduction to Mineral Processing Chevron Phillips Chemical

Introduction to Mineral Processing. In ore beneficiation, flotation is a process in which valuable minerals are separated from worthless material or other valuable minerals by inducing them to gather in and on the surface of a froth layer. Sulfide and nonsulfide minerals as ....

Ore Beneficiation an overview | ScienceDirect Topics

Jan 04, 2007· Hematite and magnetite are the most prominent iron ores. Most of the highgrade hematite iron ores (direct shipping ore (DSO)) are subjected to simple dry processes of beneficiation to meet size requirements....

Iron Ore | HowStuffWorks

Iron Ore Iron ore is where you'll find the majority of Earth's iron. Learn how iron ore is mined and eventually refined into things like steel. ... How Iron and Steel Work. by Marshall Brain ... The carbon combines with oxygen to create carbon dioxide and carbon monoxide (releasing lots of heat in the process). Carbon and carbon monoxide ......

Ecoefficient and costeffective process design for ...

Ecoefficient and costeffective process design for magnetite iron ore. Currently, the mining industry is facing several issues related to energy consumption so the optimized use of ....

Iron Ore | Geoscience Australia

Jun 30, 2016· Iron ores are rocks from which metallic iron can be economically extracted. The principal iron ores contain hematite (Fe 2 O 3) and magnetite (Fe 3 O 4). Hematite is an iron oxide mineral. It is nonmagnetic and has colour variations ranging from steel silver to reddish brown. Pure hematite contains % Fe....

Iron Ore Pelletizing Process: An Overview

The iron ore pelletizing process consists of three main steps: 1. Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives anthracite, dolomite and binders are prepared in terms of particle size and chemical specifications, dosed, and mixed together to feed the pelletizing process; 2....

Modeling Sintering Process of Iron Ore Open

Modeling Sintering Process of Iron Ore 37 scenarios using recycling outlet gas and increasing amount of inner residues such as scales and fines. In the following section these possibilities are considered. a) 5 cm from surface b) 35 cm from surface c) 75 cm from surface Fig....

processing of iron ores

Processing Iron Ore. Total technology solutions across the mining value chain TENOVA is a worldwide supplier of advanced technologies, products and engineering. RESOUR CE PA CK Iron Mining and Processing in South Vula....