processof grinding after welding

Question on Welding CR4 Discussion Thread

Mar 28, 2010· Re: Question on welding 03/28/2010 5:54 AM In cases, where it is not possible to back grind and weld on the root, the only option left out is to take more precautions and proper parameter selection, for right size of electrode / filler metal to ensure adequate root penetration, fusion and defect free welds in the initial stage itself....

Welding (pits) in welds, after grinding ? |

Sep 02, 2009· Welding (pits) in welds, after grinding ? Discussion in 'Body Restoration' started by Double R Restorations, Sep 2, 2009. Page 1 of 2 1 2 Next > Sep 2, 2009 #1. Double R ... Just keep welding, grinding, repeat until everything is nice and smooth with no pits. Sometimes it takes more than one pass with the welder to get it looking right....

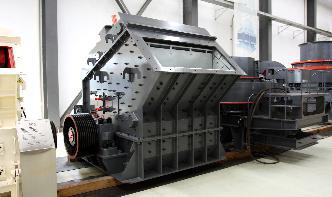

Grinder for back gauging G400 Industrial Tools

G400 Grinding disc dia. 400 mm The GBC G400 is a light, powerful, compact and versatile grinder, suitable for rapidly carrying out the main process of taping and grinding of ferrules and typical manufactured items for boilers as: . back gauging for welding root removal; polishing of dish ends, vessels, cones, poles etc...

Proc IMechE Part F: Analysis of the effect of repair ...

To analyze the geometryrelated effects of welding and grinding, the geometry of crossings (crosssectional profiles) as well as the corresponding dynamic accelerations due to passing trains are measured before and after the welding and grinding activities....

Different Types of Welding Processes: The Ultimate Guide

Welding is the process of coalescing materials such as metals or thermoplastics in order to seamlessly join them. The welding process involves applying heat and pressure to the materials being joined, in addition to a filler material, in order to create a weld pool which cools to form a strong joint....

Tips for Welding Titanium The Joe Electrode Blog

Even friction from grinding wheels (especially aluminum oxide wheels) can develop enough heat and provide the contaminants to undermine the weld. Even given these considerations, with careful preparation, any professional welder can obtain quality titanium welds. ... Thanks for the tips for welding titanium more effectively. I had no idea that ......

Welding Safety Tips and Guidelines Quick Tips #109 ...

A fire watch lasting at least 30 minutes after the welding or cutting operations is required if more than a minor fire might develop; ... They are not intended to protect against slag chips, grinding fragments, wire wheel bristles and similar hazards that can ricochet under the helmet. Spectacles, goggles or other appropriate eye protection ......

Welding Pressure Pipeliners and Piping Systems

Techniques for Welding Hot Passes After the root pass is welded, the root bead is generally very convex on the exterior of the pipe. The normal procedure is to grind the root pass to eliminate the excessive convexity. Normally, the entire weld is not ground out, rather only enough to ....

why passivation is required over the welding joint of SS ...

Jun 30, 2007· this testing is generally perform over the welding joints after grinding welding beed of ss plate ... Why passivation is required over the welding joint of SSPlate.? ... Another typical passivation process of cleaning stainless steel tanks involves cleaning with NaOH and citric acid followed by nitric acid (up to 20% at 120F) and a ......

More after grinding : Welding

" grinder with a grinding pad to take the weld down... 80 grit I think. Then a 120 " flipper wheel (to take out the deep scratches and get grain direction) on a 1/4 air die grinder. Then a brown Scotchbrite pad to polish it out...

How to perform tack welding successfully The FABRICATOR

How to perform tack welding successfully. ... What Is Tack Welding? After items to be welded together have been positioned as required, generally by clamping them on suitable fixtures, tack welds are used ... (HAZ) if the metal is rapidly quenched. In this case, even removing the whole tack weld by grinding may leave dangerous, invisible cracks ......

grinding welding processof

processof grinding after welding process of aggregate ... Welding is the process of permanently joining two or more materials together, usually .. processes like plasma cutting, gouging, grinding, fettling and guillotining can be....

Welding

Welding is a complex interaction of physical and chemical science. Correct prescription of metallurgical requirements and sound practical application is a prerequisite for successful fusion welds. The metal arc welding process uses an electric arc to generate heat to melt the parent material in the joint....

Analysis of Stainless Steel Welding Without Grinding Process

Analysis of Stainless Steel Welding Without Grinding Process ... the reason is no grinding after welding. Under normal condition, the top carrier plate is assembled by top cover, weld seams are covered. Top plate is cabinet box body, so the surface is invisible. ... the traditional process of antisalt spray and anticorrosion is generally in ......

What is thermit welding? Quora

What is thermit welding? Update Cancel. ... Rough grinding. Final grinding. Thermit Welding Mold and Crucible Diagram Figure 541. Thermit Welding Process Animation Video. Kits. ... The process of WELDING railway tracks is known as Thermit welding. 76 Views. Related Questions....

Fatigue strength of highstrength steel after shipyard ...

Fatigue strength of highstrength steel after shipyard production process of plasma cutting, grinding, and sandblasting...

Tips and Tools for Cutting, Grinding and Finishing Aluminum

Many welding professionals today approach aluminum cutting, grinding and finishing by relying on one or more of the following tools or methods. These each, however, have disadvantages in terms of cost, quality, productivity and safety. ... The better choice for cutting, grinding and finishing aluminum ......

Types of Welding Joints | Symbols | Applications ...

What is Welding? "Welding is the process of joining two pieces of metal together so that bonding takes place at the ends of joining surface". What is Welding Joint? "A welding joint is a common point or edge where two or more workpieces of plastic or metal are joined. These workpieces are joined using different types of welding processes"....

The Cause of The Slag In The Welding Tube

The Cause of The Slag In The Welding Tube. Business Articles | June 10, ... after grinding, polishing, etching metallographic the analysis of the metallographic analysis, it is found that the weld slag of the welded pipe in the thick wall is located in the position of the fusion line of the inside and outside welds, as shown in ......

Stressrelieving is needed after welding

Stressrelieving is the process generally specified after welding of most materials.. Removing or reducing the residual stresses generated by welding is required for improving the dimensional stability of weldments.. In certain applications, internal residual stresses can sum up with those generated by externally applied loads.. Then, if the yield strength of the material is exceeded ......

welding without grinding

processof grinding after welding. centerless grinding welding Analysis of Stainless Steel Welding Without Grinding Process. Analysis of Stainless Steel Welding Without Grinding Process. Welding Fumes Contain Toxic Metals. Welding fumes contain toxic metals, including manganese, that can damage your brain and nervous system. ......

Is the weld stronger if you grind it flat | MIG Welding Forum

Feb 09, 2015· Other than for appearance I was told the weld is stronger if you grind flat the waste weld metal. Is this because the metal is less flexable and... Log in or Sign up. ... I used a hobby tool to brighten up the metal for welding but the tool isn't strong enough to grind back the metal which means i'll probably have to leave the welds as they are ......

Sanding/Smoothing steel and welds

Jul 29, 2010· Until now I have just been grinding my welds down with an angle grinder and grinding wheel however after painting the grinding wheel leaves deep marks that can still be visible. ... Here you can join over 40,000 Welding Professionals enthusiasts from around the world discussing all things related to Welding. You are currently viewing as a ......

Development of a Rail Grinding Machine for Welds

· anual finishing with a stone grinder after rough grinding with M the machine could be completed within 25 minutes each time. · The machine could easily be set immediately after welding. We found no damage to the milling cutter tip after the final test....

Guard your eyes and face when welding, cutting and grinding

Home » Guard your eyes and face when welding, cutting and grinding. Guard your eyes and face when welding, cutting and grinding. April 12, 2010. ... Exposure to radiation from arc welding can occur when an individual's eyes are exposed to the three types of direct or reflected light: visible, ultraviolet (UV) and infrared (IR)....