prodution process of ores

Innovations: Introduction to Copper: Mining Extraction

Introduction to Copper: Mining Extraction Copper Applications in Metallurgy of Copper Copper Alloys. By Vin Calcutt. ... At current world mine production, this represents a million years' supply of copper theoretically available in the mineable portion of the earth's crust. ... the socalled SXEW process. Sulfide ores are not efficiently ......

An Australian Company Says Its New Extraction Process ...

An Australian Company Says Its New Extraction Process Could Bring Unlimited Lithium Supplies ... making it economically viable for recovering lithium from lowgrade ores, found in micas, which are ......

Chapter 6 Copper Production Technology Princeton .

Zqsolution mining is the leaching of ore with waterbased chemi cal solutions. In situ solution mining treats the ore in place;, without miningIt first. open pit mining offers the highest production rates and leaves the least ore behind. However, underground mining can reach greater depths....

graphite manufacturing process from ore YouTube

Sep 30, 2012· According to the features of graphite ore, its basic process is Two sections or Three sections crushing, One section or Periodicity grinding, and ....

Bismuth Production

Production. Lead concentrates which are obtained from lead, leadzinc and complex ores are the main source of bismuth. The common bismuth concentration in them is several hundredths of a percent, sometimes they reach %. Bismuth gets into the crude lead during the processing from which it is separated after refining....

An Australian Company Says Its New Extraction Process ...

The process is less energyintensive than traditional approaches, making it economically viable for recovering lithium from lowgrade ores, found in micas, which are currently ignored by the ......

vibromagnetic separator production process of gold ore best

Sep 08, 2018· flotation separation process best sell. Ore Flotation Separation Process Wholesale, Ore Flotation. Rock Ore Gold Mining Plant With Flotation Separating Process Best selling products gold ore mining production line beneficiation process explained. Get Price Sell Tin Ore....

Mining and Refining – Process World Aluminium

Alumina is used for the production of aluminium metal, through the Hall–Héroult electrochemical smelting process. The Bayer Process is the most economic means of obtaining alumina from bauxite. Other processes for obtaining alumina from metal ores are also in use in some refineries, particularly in China and Russia, although these make up a relatively small percentage of global production....

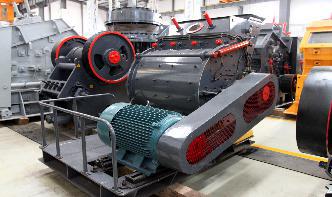

COPPER Copper production TU Delft

Figure 1: Overview of copper production Benefication process Figure 2: Overview of a typical beneficiation process at a concentrator Sulfidic copper ores are too dilute for direct smelting. Smelting these materials would require too much energy and very large furnace capacities. The copper ore coming from the mine ( – 1 %...

manufacturing process of pozzolana iron ore

Feb 27, 2018· manufacturing process of pozzolana iron ore ; manufacturing process of pozzolana iron ore. Pop Cement, Pop Cement Suppliers and Manufacturers . Pop Cement, Wholesale Various High Quality Pop Cement Products from Global Pop Cement Suppliers and Pop Cement Factory,Importer,Exporter at....

ore dressing ore copper ore production process

copper ore dressing production process efficient. Dec 27, 2018copper ore dressing production process efficient How copper is made material, used, processing, steps . Process The process of extracting copper from copper ore varies according to the type of ore and the desired purity of the final product....

production process of iron ore

Iron Smelter, Iron Smelter Suppliers and Manufacturers production process of iron ore BF blast furnace with raw iron ore 60% ironmaking smelter. Add to Compare ... iron smelter for produce iron balls,used waste iron for recycling....

ore dressing ore copper ore production process

ore dressing ore crushed rock production process. It is a process of ore preparation, milling, and ore dressing or ore beneficiation. It is done in order to produce a concentrate containing most of the ore minerals and a tailing part ....

Aluminium production process

ALUMINA PRODUCTION. Bauxite is crushed, dried and ground in special mills where it is mixed with a small amount of water. This process produces a thick paste that is collected in special containers and heated with steam to remove most of the silicon present in bauxites. The ore is loaded into autoclaves and treated with lime–caustic soda....

ColtanMining and Processing, Technology, Production ...

Coltan is a dull metallic ore found in major quantities in the eastern areas of Congo. When refined, coltan becomes metallic tantalum, a heatresistant powder that can hold a high electrical charge....

The Modern Steel Manufacturing Process The Balance

The Modern Steel Production Process. Today, steel production makes use of recycled materials as well as traditional raw materials, such as iron ore, coal, and limestone. Two processes, basic oxygen steelmaking (BOS) and electric arc furnaces (EAF), account for virtually all steel production....

Mining and Extraction: Oxide Ores processes for ...

Most of the copper ores mined today are oxide or sulfide ores. Extraction of sulfide ores is covered in more detail in Copper Mining and Extraction: Sulfide Ores (11–14), but is introduced here because an important byproduct of this process is used for the extraction of oxide ores....

process of concentration of ores Mineral Processing EPC

Copper Ore Processing Plant. process of concentration of ores offers 1170 copper ore processing plant products. About 54% of these are mineral separator, 10% are crusher, and 10% are mine mill....

Iron ore pellets and Pelletizing processes |

Iron ore pellets and Pelletizing processes. Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh with additives like bentonite and then shaping them into oval/spherical lumps of 816 mm in diameter by a pelletizer and hardening the balls by firing with a ....

Iron processing |

Deposits with less than 30 percent iron are commercially unattractive, and, although some ores contain as much as 66 percent iron, there are many in the 50–60 percent range. An ore's quality is also influenced by its other constituents, which are collectively known as gangue....

Iron Ore and Pellets

Iron ore is found in nature in the form of rocks, mixed with other elements. By means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies. The iron ore produced by Vale can be found in houses, cars and appliances....

Beneficiation of Iron Ores |

Beneficiation of Iron Ores. Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron. magnetite)....