raw feed size of gravel for aggregate crushing

gravel feed crushing plant

Aggregate Crushing PlantCrusher and Grinding Mill Supplier. Feeding Conveying; SBM news, Products Plants SBM has been serving the aggregate crushing grinding industry for over 20 years, . ... the wet sand and gravel raw feed after initial crushing and screening, . MSHA Metal/Nonmetal Mine Fatal Accident Investigation,...

how to size a gravel crusher

how to size a gravel crusher A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in ......

rock and gravel crushing plant

While both sand and gravel plants, and crushed stone plants, are built by many At a typical sand and gravel plant, raw material from a hopper at a dumping. Get Price Gravel Pits, Quarries, and Aggregate Crushing and Screening Plants. Gravel Pits, Quarries, and Aggregate Crushing and Screening Plants. A rock crushing operation....

Gravel Crushing Contract Workshop North Dakota Local ...

~ Good Gravel ~ Gravel Crushing Contract Workshop Steve Monlux et al stevemonlux October 22, 2013 ... –Selective feed from pit, Reject a portion of minus #4, use high ... Bentonite by aggregate weight and pug mill mix. * Best suited for dry climates GRM 42 Improvement Areas...

SIZE REDUCTION BY CRUSHING METHODS By .

All operations in size reduction, both crushing and grinding are of course determined by the feed characteristics of the minerals (rock/ore) moving into the circuit. The key parameters we need are the...

best stone crushing plant for gravel

One of our customers want to buy cone crusher for 60 t/h ballast crushing plant Senegal, the raw material is high quality granite and the feeding size is around 350 required ballast size range are 10 20 mm, 20 40 mm and 40 80 mm....

backhoe sized grizzly gravel screen Mineral Processing EPC

This process repeats until the materials are crushed to the required size and . Raw materials are firstly quarried by excavator. The grizzly vibrating feeder equipped with feeding grate can screen the materials primarily. . Through a series of crushing and screening, the ....

Manufacturers Rock Gravel Aggregate Concrete Stone ...

China Manufacturers Rock Gravel Aggregate Concrete Stone Crushing Equipment for Sale, Find details about China Stone Crushing Equipment South Africa, Limestone Crushing Equipment from Manufacturers Rock Gravel Aggregate Concrete Stone Crushing Equipment for Sale Shibang Industry Technology Group Co., Ltd....

gravel screening crusher

Powerscreen aggregates, sand gravel case studies crushing ... Powerscreen tracked crushers and screens are designed to take raw feed and reduce them to usable aggregates sizes. The versatility of having a fully mobile tracked crusher or screen allows the customer to process raw materials into finished aggregate quickly and efficiently....

Screening Aggregate Sizes

Aggregates, Sand Gravel Powerscreen Crushing . Home > Applications > Aggregates, Sand Gravel. ... screening and washing ... screens are designed to take raw feed and reduce them to usable aggregates sizes. Chat With Sales » Construction Aggregates. Information on the Construction Aggregates ... the material goes through various ......

United States Environmental Protection Agency General ...

United States Environmental Protection Agency. General Permit for New or Modified Minor Sources of Air Pollution in Indian Country . ... process rock, sand, gravel, or mineral aggregate or that mines rock, stone, sand and gravel for construction. As ... reduce particle sizes. In rock crushing operations, rock is loosened by drilling and ......

Applications

MPS crushing and screening equipment is designed to take raw feed and reduce them to usable aggregates sizes. The versatility our crushing and screening equipment allows the customer to process raw materials into finished aggregate quickly and efficiently....

Crushing 101 | Masaba

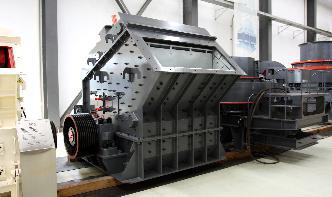

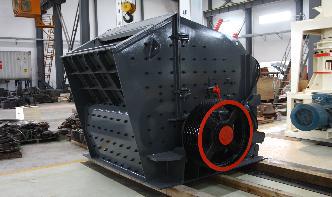

Jaw Crusher. Many producers refer to jaws as "breakers" meaning that they break the rock down to a size manageable for the secondary crushers. The numbers used in referring to jaw crushers, such as 3042, refer to the opening size at the top of the jaw. The 30 is 30" left to right, the 42 is 42" across the jaw....

gravel screening crusher

Powerscreen aggregates, sand gravel case studies crushing ... Powerscreen tracked crushers and screens are designed to take raw feed and reduce them to usable aggregates sizes. The versatility of having a fully mobile tracked crusher or screen allows the customer to process raw materials into finished aggregate quickly and efficiently....

Crushing for particle shape Aggregates Manager Magazine

A primary jaw or impact crusher may take a feed with a top size of 39 inch. The secondary crusher could take an 8inch to 10inch feed. The top size feed for the tertiary crusher may be 4 inch, but typically it is 2 inch....

APPENDIX D Air Quality Calculations

Air Quality Calculations. 1 AIR QUALITY CALCULATIONS ... After being transported to the processing plant, the wet sand and gravel raw feed is stockpiled or emptied directly into a hopper, which typically is covered with a "grizzly" of parallel bars to ... crusher for size reduction, to produce crushed aggregate, or to produce manufactured sands...

feed sieve in limestone crushing

Aggregate quarry plant in Philippines including, Jaw Crushers. Feed Pellet Grading Sieve/Feed Pellet Crusher Manufacturer feed sieve in limestone crushing, Feed Pellet Grading Sieve Application The rotary grading sieve is used to screen and grade the feed pellets after cooling or crushing, thus can get the qualified Limestone processing plant Mining, crushing, grinding,limestone ......

River Stone Crushing Plant, Cobble/Limestone Aggregate ...

with grain size larger than 5mm are called coarse aggregates, and there are two kinds of gravel and pebble commonly used. Particle size grading: 510mm,1020mm, aggregate with the grain size below 5mm is called fine aggregate....

5 Aggregate Production

Shot Rock or Gravel Bank Crushing Scalping Primary Crushing Secondary and Tertiary Crushing Impact Crushing ... size more uniform. One way to choke feed is with a surge hopper and a controlled beltfeed to the cone crusher (Figure 510). ... Producer is required to decide carefully the mode best suited to the raw material. Figure 513. Vertical ......