roller mill operating requirements

Auxiliary Roller Mills Manufactured by RENN Let You ...

The RENN Auxiliary PTO Roller Mill is specially designed to allow operators to run a Roller Mill and Bagger with one tractor. This convenient way of rolling and bagging grain increases harvest efficiency by reducing manpower requirements, eliminating tractor needs, and saving on fuel consumption....

raymond roller mill operation manual YouTube

Oct 09, 2018· More Details : raymond roller mill manuals operation and maintenance manual loesche vertical roller mill raymond mill ......

operating operating principles of si roller mill machine

Operating principles of Six roller mill machine Machine Listing Fourdrinier Machines pulpmill Pulp Mill Equipment, Sur, Operating principles of Six roller mill machine,Used and surplus 60 Meter trim Pulp machine may be used as basis for pulp or paper, Pulp Mill Associations and Professional Organization Machine Listing, diameter Nip ....

Operating Parameter Of Vertical Roller Mill

In this paper, vibration characteristics of a Vertical Roller Mill (VRM) are studied by using physical parameters of an operating VRM. The mathematical model is. Get More Info. image. vertical roller mill vibration vertical roller mill vibration....

Raymond Mill, The Standard Operating Theory ...

Raymond mill works closely under the centrifugal force on the grinding ring rolling by shovel blade materials to roll grinding and grinding ring middle, material crushing ... by analyzing the interaction machines and fans can meet the different requirements of users. ... The Standard Operating Theory Of Raymond Mill....

Raymond Mill,Raymond Mill Working Principle

Raymond mill host another vulnerability is grinding roller, under normal circumstances, Raymond mill for grinding roller in use for some time, this according to customer's materials, frequency of use and other factors to determine whether the operation. To limestone ....

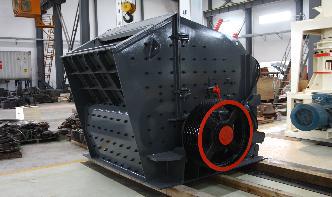

Roller Mill: Components, Designs, Uses, Advantages and ...

Roller mill, a form of compression mill, consists of a single, double or triple cylindrical heavy wheel mounted horizontally that are stacked and enclosed in a steel frame; one of the roller is run by a motor and the others are rotated by friction as the material is drawn through the gap between the rollers....

Vertical Roller Mills

Reduce operating costs; Industries. Industries. Choose your industry or see all industries we operate in. ... As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to ... Capacity requirements for new cement and power plants and grinding units are ......

Ball Mills Metallurgist Mineral Processing Engineer

Ball Mill Charge volume. When calculating a mill 40 % charge volume is generally used. In pebble and ball mills quite often charge volumes close to 50 % are used. In a pebble mill the pebble consumption ranges from 3—15 % and the charge has to be controlled ....

roller mill | Craft Beer Brewing

Roller Mill is the most common device for crushing malt and grain into grist in preparation for the mash. Roller mills differ by the number of tandem operating rollers and by the treatment of the malt or grain prior to and during the milling operation. There is dry milling, conditioned dry milling, and wet milling....

Operating Principles Of Six Roller Mill Machine

operating of ultrafine mill Rock crushing machine. operating principles of six roller mill machine SBM Machinery SBM is one of the biggest manufacturers in Aggregate Processing Machinery for the operating principles of six roller mill machine, sand gravel, quarry, mining, operation principle of raw mill ....

Modern Processing Techniques to minimize cost in Cement ...

Horomill is suitable for grinding raw meal, cement and minerals, whereas Cemax Mill is mainly for cement grinding. The mill can be used for pregrinding and finish grinding. This mill system claims to have advantages of ball mill, roller mill and roller press in terms of reliability and energy savings....

Operational parameters affecting the vertical roller mill ...

In the airswept mode, the verticalrollermill and a high efficiency dynamic classifier are suited above each other as a single unit ( Fig. 1 ). Material is fed to the grinding chamber and transported by table rotation to the grinding gap between the fixed grinding rollers and the mill table....

Pulverizers / Mills

In addition, we continually develop new technologies, upgrades, replacement parts, and inventory management programs to improve reliability and performance, and to reduce operating and maintenance costs of our BW Roll Wheel and E/EL pulverizers, as well as CEtype mills....

Raymond Mill Operating Points Loesche Vertical Roller Mill ...

roller mill operating requirements YouTube. Feb 13, 2016· Raymond Mill,Sand Making Machine,Vertical Roller Mill Zenith manufacturers supply sand making machine, vertical roller mill,raymond mill, crushing machine. More products do in sales....

THREE ROLL MILLS

As the general purpose range of Three Roll Mills, this model series is distinguished as an entry model in the laboratory and for the production of small volumes. The precise onehand setting of the roller gap down to 10 µm guarantees excellent, reproducible product fineness....