steps in mining iron ore

Fortescue Metal steps up iron ore sales to India

Argus reported that Australian iron ore producer Fortescue Metals has stepped up sales to India, diversifying from the traditional market of China where sales of its lowgrade fines have been ......

Premier Mark McGowan steps into battle for peace at Sino ...

Mining. Premier Mark McGowan steps into battle for peace at Sino Iron over stalemate between CITIC and Clive Palmer's Mineralogy. ... dam is: a big, ugly rubbish dump which is filling up fast because for every three tonnes of rock mined at magnetite iron ore operations such as Sino Iron....

Beneficiation of Iron Ore Mineral Processing Metallurgy

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, ... Multistage cleaning steps generally are not necessary. Often roughing off the silica froth without further cleaning is adequate. ... ENTER our Mining Equipment' Store....

iron ore mining steps

iron ore mining steps The iron ore mining is a complex and a very long process. There are various tasks involved in the iron ore mining. The first step involves the iron ore is ......

steps in iron ore extraction

A wide variety of mining cobalt ore options are available to you, such as flotation Leaching Tank for gold,copper,silver,iron,tungsten,lead,cobalt .. Tungsten cobalt step tungsten carbide insert expanding drill bits special carbide drill bit....

The Extraction of Iron Chemistry LibreTexts

Extracting iron from iron ore using a Blast Furnace. ... The significant reactions occuring within the Blast Furnace can be described via the following steps showing how the reducing agent varies depending on the height in the furnace ( on the Temperature). ... Loss of landscape due to mining, processing and transporting the iron ore, coke ......

what are the steps for concentrating and smelting ...

copper smelting process | Process Crusher, Mining Equipment Exports A typical pyrometallurgical copper smelting process, as illustrated in Figure 1, includes 4 steps: roasting, smelting, concentrating, and fire refining. Lead and Zinc Smelting production process consists of four steps: sintering, smelting, drossing, and refining....

Mining Leveling Guide Level Mining with Smelting from 1 ...

I recommend Mithril because you will have to smelt Mithril in the next step, so at least you have to buy fewer ores. But you can mine any other ore that's higher level than Iron Ore. 150 200. 150 185 Smelt 55 x [Mithril Ore]. If you can buy 25 [Truesilver Ore] at the Auction House then you could stop smelting Mithril at 175 and jump to the next part. So, this party really depends on how many Truesilver you can ....

Iron processing |

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the ....

Beneficiation of Iron Ore Mineral Processing Metallurgy

Beneficiation of Iron Ore. This also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500mesh for liberation of the iron minerals from the siliceous gangue....

The Mining Process – Waihi Gold

The Mining Process. 1. Mining – open pit and underground To define the ore from the waste rock, samples are taken and assayed. Assay results are used to mark out areas of ore and waste rock, which are mined separately. Some of the harder areas require blasting to loosen the rock prior to excavation by hydraulic diggers....

Iron ore Wikipedia

Production and consumptionEdit. Mining iron ore is a high volume low margin business, as the value of iron is significantly lower than base metals. It is highly capital intensive, and requires significant investment in infrastructure such as rail in order to transport the ore from the mine to a freight ship....

How Is Iron Extracted From the Earth? |

Full Answer. Magnetite and hematite are iron oxides; however, the extraction of iron from an iron oxide involves a series of steps that begins when mined iron ore is crushed into smaller pieces by a crusher and then washed. The second step in the process is calcination or roasting of the ore, which removes certain impurities,......

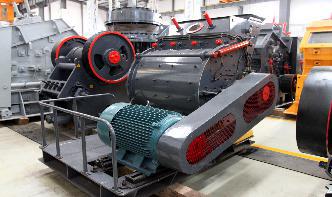

steps in the process for open pit mining of iron ore in ...

steps in the process for open pit mining of iron ore in south africa. heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry....

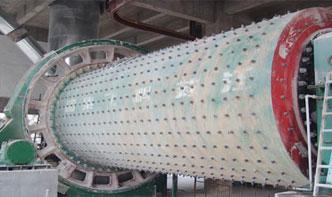

the major steps in the process of iron ore mining

the major steps in the process of iron ore mining Long Lasting Working Tph Ball Mill,Ball Mill With Engineer . Mill,Long Lasting Working Ball Mill,160 Tph Ball Mill from Mine Mill Supplier or can be equipped with three types of tank adapting to different dressing process....