the process of blasting in iron ore

The Blast Furnace and extraction of Iron from its Iron Ore ...

The Blast Furnace and extraction of Iron from its Iron Ore study guide by macleodhannah includes 14 questions covering vocabulary, terms and more. ... What are the two molten substances found at the bottom of a blast furnace? ... This reaction provides the heat energy for the extraction process as it is an exothermic reaction....

Understanding Iron Ores and Mining of Iron Ore |

Understanding Iron Ores and Mining of Iron Ore. Each of the holes is detonated just a millisecond apart, resulting in a pile of crude iron ore that is broken apart to a minus 2 m x 2 m size. The wide holes in the ground created by drilling, blasting, and ore removal are referred to as 'open pits'....

Creating Iron | HowStuffWorks

How Iron and Steel Work. A blast furnace is charged with iron ore, charcoal or coke (coke is charcoal made from coal) and limestone (CaCO 3 ). Huge quantities of air blast in at the bottom of the furnace, and the calcium in the limestone combines with the silicates to form slag. Liquid iron collects at the bottom of the blast furnace,......

Pelletizing Wikipedia

Pelletizing of iron ore. The configuration of iron ore pellets as packed spheres in the blast furnace allows air to flow between the pellets, decreasing the resistance to the air that flows up through the layers of material during the smelting. The configuration of iron ore powder in a blast furnace is more tightlypacked and restricts the air flow....

IRON MINING PROCESS

IRON MINING PROCESS Blasting Taconite is a very hard rock. Using explosives, the taconite is blasted into small pieces. Transportation The taconite pieces are scooped up by electric shovels. Each shovel can hold up to 85 tons of rock! The shovels place the taconite into giant dump trucks. These trucks are as big as a house and hold up to 240 tons...

copper ore blasting mirror machine

copper ore blasting mirror machine_High Quality AlucobondZhejiang Zhong Ming Ji Xiang Building Material Equipment Co., Ltd. . ... Process blasting, deburring, painting, powder coating polishing, electropolishing, mirror polishing, electrogalvanizing. Get Price ... combination wrench ball mill machine in estonia Next: cone iron ore flotation in ......

Optimized Iron Ore Blast Designs for SAG/AG Mills Jack ...

Optimized Iron Ore Blast Designs for SAG/AG Mills Jack Eloranta Eloranta Associates Inc . Abstract Few "minetomill" issues inspire as heated debates as blasting for SAG AG mills. Increased blast ... savings in the drilling through grinding process by increasing powder factor by 25%....

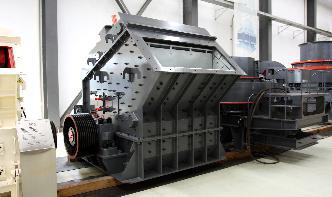

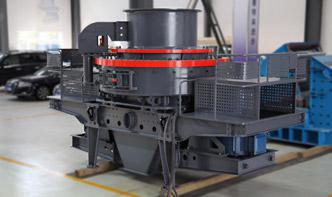

Mining of Iron Ores |

Mining process. In crushing and washing plants the processing of the ore is carried out. Processing of the ore ranges from simple crushing and screening and separating various size fractions of the ore to the processes that beneficiate or upgrade the quality of the iron ore ....

Lesson 1: How Do We Mine Iron Ore? Center for Science ...

Students will be able to describe the site where hematite is mined. Students will be able to describe the process of hematite being turned into iron ore pellets and transported to a steel mill. Students will be able to discuss transportation systems used in this process. State Standards. II....

iron ore blasting iron ore flotation cell machines

iron ore plant processing flow; prod gold flotation cell machine iron ore making gold; ball mill the ball mill iron ore; iron ore mine processing process flotation cell machine process; iron ore ball mill efficient; ball mill iron ore efficient equipment; iron ore dredging machine for sale manganese ball mill; iron ore magnetic separator screen ......

iron ore blasting process videos

iron ore mining blasting process Conventional mining methods using inpit blasting and drilling will be applied at the openpit mine. Taconite ore from the mine will be extracted and stockpiled before being subjected to twostage crushing....

Iron Mining Process Minnesota Iron

From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation's steel. Blasting Taconite is a very hard rock. Using explosives, the taconite is blasted into small pieces. Transportation The taconite pieces are scooped up by electric shovels....

Process Of Blast Furnace

Blast furnace iron making is the main method for modern steel production,the process of blast furnace is an important part....

What's the process of iron ore mining? Quora

This is the process involved in iron ore mining. The process of iron ore mining, the first step is first ore is crushed and transported back to the OPFs for grinding and the wet scrubber removes the waste from the ore and categorizes it into oversize, midsize and undersized....

How A Blast Furnace Works – twinkletwinklelittlestar

Apr 28, 2014· The Process. Iron oxides can come to the blast furnace plant in the form of raw ore, pellets or sinter. The raw ore is removed from the earth and sized into pieces that range from to inches. This ore is either Hematite (Fe2O3) or Magnetite (Fe3O4) and the iron content ranges from 50% to 70%....

iron ore efficient blasting process

iron ore efficient blasting process. Mining Placer mining Britannica. Mining Placer mining Placers are unconsolidated deposits of detrital material containing valuable minerals. The natural processes by which they form range from chemical weathering to stream, marine, and wind action....