three stage rolls mill for grinding ore

stirred mill for ore grinding

Which Grinding Mill is Best for Regrinding by Types 911 Metallurgist. Apr 11, 2018 ... Ball Mills and stirred mills are applied across a wide range of applications, but for each ore ....

one stage grinding ball mill was applied

Mill (grinding) Ball mills are commonly used in the manufacture of Portland cement and finer grinding stages of mineral processing, one example being the... Get Price effects of grinding media shapes on ball mill performance Core. Spherical grinding media are predominantly used in final stages of ore grinding. The ......

Iron ore pellets and Pelletizing processes |

There are four stages involved in the production of pellets. ... The dried material is fed to the ball mill for grinding. Concentrate / ground iron ore of typical size 80% sub 45 microns is required to be at 9% moisture. ... Ore fines are lifted upwards until the friction is overcome by gravity and the material rolls down to the bottom of the ......

Mill for the pharmaceutical industry All industrial ...

impact mill / horizontal / for powders / for the pharmaceutical industry Tube Mill control . Make a request. impact mill. Tube Mill control . Rotational speed: ... two and threestage grinder, central drive and a straightforward roller change. ... disc mill / horizontal / for ore / for the pharmaceutical industry DP200. Make a request. disc ......

Metallurgy Mineral Processing

stage of rougher flotation, followed by a scavenger stage of flotation. The objective of passing through the rougher and scavenger flotation circuits is to maximise recovery of the desired minerals into relatively low grade concentrates that may typically contain 515 weight percent of the ore feed, (directly related to ore ....

Relationships between comminution J energy and product ...

property of an ore (kWh/t); for grinding from the product of the final stage of crushing to a P80 of 750 lm (coarse particles) ... three ore samples. A laboratory scale ball mill (D x L = 203 x ... observed that the Bond ball mill work indices for the ore (Wi) varies from to kWh/t....

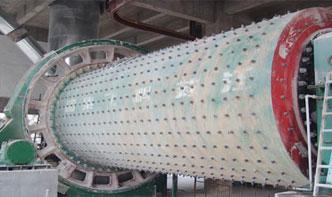

Ball Mill_The Nile Co., Ltd.

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Ball mills have been designed in standard sizes of the final products between mm and mm in ....

Autogenous Grinding Information Mine

Autogenous mills are available for both wet and dry grinding. The diameter of autogenous mills is normally two to three times the length. The ore charge is usually 25 to 35% of the mill mills have grate discharges to retain the coarse grinding media in the mill....

Modelling and Simulation of the Santa Rita Mine Milling ...

Reclaimed ore is conveyed at 860 t/h to the grinding circuit, which includes one SAG mill, two pebble crushers and two ball mills. The grinding circuit is pumped to a desliming stage at a P 80 of 125 μm....

Grinding

Grinding Grinding is the last stage in the process of comminution and is often said to be the ... the balls roll or cascade to abrade the ore to produce finer particles; this also ... fed to the mill for grinding. As the ground ore is discharged from the mill it is again...

Mineral processing | metallurgy |

Mineral processing: Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. ... This material is the feed for the grinding mill. Grinding. In this process stage, the crushed material can be further disintegrated in a cylinder mill, ... various operations ......

Three / Five Roller Mill For Mineral Grinding

three five roller mill for mineral grinding three five roller mill for mineral grinding Hot Products. Ball Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage ....

Grinding Mills and Their Types |

The grinding mills are categorized in three groups, namely (i) tumbling mills,(ii) roller mills, and (iii) very fine grinding mills which include (a) high speed pulverizing or hammer mill, (b) vibrating mill, (c) pin mill, (d) turbo mill, (e) fluid energy mill, (f) stirred media mill....

Fluor Global Engineering and Construction Company EPC ...

coarse ore conveying, grinding, flotation, thickening, concentrate storage and loadout. Coarse ore from a 4,500t live stockpile is fed to the SAG mill feed conveyor by four plate feeders controlled by a weightometer. The 5m x grate discharge SAG mill could be converted to......

China's talc industry development trends is good in 2017

Talc as a nonmetallic mineral has an irreplaceable position in the human production and life, advanced talc grinding mill is also an important place in talc industry. In 2017, China's talc ......

Chrome Ore Mining Process Xinhai

Chrome Ore Mining Process 【Introduction】: ... smaller crushed chrome ore is fed to ball mill for grinding. Inside the ball mill, the crushed chrome ore will grind the ore to about mm with 3inch steel balls. ... Then, tailings are delivered into the jig in the next stage for screening for 4 times like this....

Major Mines Projects | Highland Valley Mine

The three metre by metre gyratory crushers reduce the pit run ore to minus metres in size. Crushed rock is conveyed to three covered stockpiles that feed five parallel grinding lines in the Mill. Primary mills consist of three semiautogenous (SAG) mills and two autogenous (AG) mills....

Application of Operating Work Indices in Autogenous ...

the ore P 80 = The 80% cumulative passing size of the product in microns F 80 ... AG/SAG grinding mill can be properly assessed by using the Wio concept, the T 80 ... Corrected Ball Mill Feed, and 3. T2': the particle size distribution of the Corrected Ball Mill Feed....