turning and grinding in one operation

Machining Material removal processes

Machining. The most common single point cutting process is turning, in which the workpiece rotates and the cutting tool feeds into the workpiece, cutting away material. Turning is performed on a lathe or turning machine and produces cylindrical parts that may have external or internal features....

Various Types of Operations Performed on Lathe Machine

The grinding operation is carried out after rough turning, to provide an accurate finish to the work piece by removing a small amount of material. Counter boring The process of boring a hole to more than one diameter on the same axis is known as counter boring....

Chapter 5: Surface Grinder – Manufacturing Processes 45

Replacing the Grinding Wheel. Open the wheel case. If the wheel case is very tight, this may require a pair of brace wrench, wrench and a rubber mallet. Remove the metal plate on top by loosening the screws that are holding it to the wheel case....

Basics of Grinding Manufacturing

centerless grinding Grinding in which the workpiece is supported on its OD and rotated around an axis created by this reference surface. The workpiece is free to shift, and if the support surface is the one being ground, the axis of rotation also shifts. centertype grinding Grinding ....

Tools and Equipment | Smithy AutoMate CNC Machine Tools

Tools and Equipment. ... The male center or plain center is used in pairs for most general lathe turning operations. The point is ground to a 60° cone angle. When used in the headstock spindle where it revolves with the workpiece, it is commonly called a live center. ... (Figure 329) is a machine tool attachment specially designed for ......

Difference Between Machining and Grinding

Grinding is one abrasive cutting process used mainly for finishing. Abrasives of grinding wheel have no specific geometry. ... close tolerance and surface finish are usually not possible by conventional machining processes like turning, milling, drilling, etc. Grinding can be advantageously utilized for such purposes, especially when desired ......

Turning Boring – Houston Centerless Grinding Service, LLC

Oil rises to oneweek high on Saudi cuts and weaker dollar Oil rises as Saudis are said to continue with deeper supply cut Oil's big reset: Energy majors learn to thrive after price crash...

What is the differences between milling and turning Answers

What is the differences between milling and turning? ... operation. iron ore fines are naturally available on iron ore and genetared during loading and grinding ... drill is one of these....

Grinding Replaces Machining in Aerospace Applications ...

Grinding Versus Machining in Aerospace Applications. ... one with Norton Targa ceramic aluminia TG2 grain and the other Norton Quantum ceramic alumina 5NQX grain. ... Similar to the slotting case, another example uses wheel technology, replacing the turning operation with grinding....

Surface Grinding, Milling, Turning and Facilities List ...

Surface Grinding, Milling, Turning and Facilities List When it comes to our business, we offer our customers a powerful resource and a recipe for success. Listed below is a comprehensive list of services we offer our clients....

Mini Lathe Operations: Parting

Parting Operations. Parting uses a bladelike cutting tool plunged directly into the workpiece to cut off the workpiece at a specific length. It is normally used to remove the finished end of a workpiece from the bar stock that is clamped in the chuck. Other uses include things such as cutting the head off a bolt....

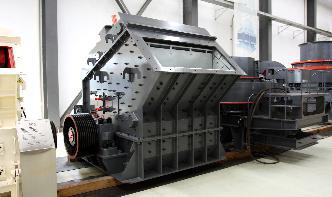

Vertical and horizontal Turning/Grinding Centers

INDEX Turning/Grinding Centers Turning and grinding – of course with INDEX The INDEX Turning/Grinding ... operation during turning 2. Quality advantage: • Utmost accuracy in the micron range ... and spindles in one screen • Start conditions for safe program launch by guided...

Machining surface finish chart, comparator, method, degree ...

Machining surface finish chart, comparator, method, degree, Ra, Rz, RMS As for machining to iron and steel castings, the surface finish smooth degree is also an important requirement. The following is the conversion chart is from dandong foundry, for Ra (um), Ra (micro inch), Rz (um), RMS and finish degree in China and USA, including the ......

8 Principles of Centerless Grinding

In the machining world, turning gets all the attention. Lathes and mills are the flashy stars — in fact, they ARE machining to most people. ... That's why we like to say that where machining ends, the centerless grinding process begins. ... there is no deflection during the grinding operation. Centerless grinding is virtually continuous ......

Cutting and Grinding Safety | Gribbins InsulationGribbins ...

Cutting and Grinding Safety. ... Turn the wheel guard so that the closed area is towards the operator. First switch on and only present the tool to the workpiece once it is running. ... Ensure that there is noone present in the area at risk. Run the angle grinder for approximately 30 seconds....

Modern Manufacturing Midterm Flashcards | Quizlet

Modern Manufacturing Midterm. Chapters 1, 5, 1011, 2021. ... In using the orthogonal cutting model to approximate a turning operation, the chip thickness before the cut to corresponds to which one of the following cutting conditions in turning: (a) depth of cut d, (b) feed f, or (c) speed v? ... A broaching operation is best described by ......

MACHINING OPERATIONS AND MACHINE TOOLS .

• Turning – a machining process in which a singlepoint tool remove material from the surface of a rotating work piece....

Mini Lathe Operation: Turning home page

Turning Operations. Turning is the removal of metal from the outer diameter of a rotating cylindrical workpiece. Turning is used to reduce the diameter of the workpiece, usually to a specified dimension, and to produce a smooth finish on the metal. Often the workpiece will be turned so that adjacent sections have different diameters....

EMAG VLC 100 GT Combines Vertical Turning and Finish ...

EMAG's VLC 100 GT combines vertical turning and finish grinding operations in one machine to speed up workflow. When it comes to machining times, combining various machining processes in one setup offers enormous savings potential....

Grinding (abrasive cutting) Wikipedia

Grinding (abrasive cutting) Jump to navigation Jump to search. This ... (turning, milling, drilling, tapping, etc.) ... During the grinding operation one side of the wheel takes part in the grinding operation whereas the other side of the wheel is being dressed by electrochemical reaction. The dissolution of the metallic bond material is caused ......