typical cement production plant layout

How Cement Is Made

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process....

TYPICAL FACTORY LAYOUT vs THE TOYOTA APPROACH

TYPICAL FACTORY LAYOUT vs THE TOYOTA APPROACH TRADITIONAL FACTORY Each silo is as efficient as possible Traditional layouts assume that more quantity is the key output. Batchandqueue system. Allows inventory to build up and wait. Theory is reduced change over and transport cost....

Cement Manufacturing Plant Project Report: Industry Trends ...

Plant Layout Plant and Machinery Raw Materials Utilities Manpower Other Capital Investments. 7. Cement Manufacturing Plant: Loans and Financial Assistance 8....

INDUSTRIAL CASE STUDY THE EMENT INDUSTRY

The cement industry in California consists of 31 sites than consume roughly 1,600 GWh and 22 million therms per year. Eleven of these sites are involved in fullscale cement production, while the remainder of the facilities provides grinding and mixing operations only. The eleven full...

Environmental Impact Assessment and Management Plan

This situation is therefore favourable for a cement plant to be established in Namibia. Location The location of the quarry site and proposed cement plant is on the farm Sargberg (Farm No. 585) – refer to Figure 1. The site is situated 16 17 km northeast of Otavi in the Otjozondjupa Region of Namibia....

Chapter 4 A typical plant layout for a drymix Equipment ...

shotcrete at production rates up to 2 cubic yards per hour. b. Plant layout. A typical plant layout for a drymix shotcreting operation, including air and water supplies, gun, delivery hose, and nozzle, is shown in Figure 43. 43. WetMix Process Cement, aggregates, and admixtures (except accelerators) are thoroughly mixed. The mixture is fed ......

GUIDE SPECIFICATION FOR PLANTPRECAST CONCRETE .

GUIDE SPECIFICATION FOR PLANTPRECAST CONCRETE PRODUCTS PART 1: GENERAL REFERENCES ... Precast Concrete Unit Data Design Data Test Reports Certificates DESIGN Standard Precast Concrete Unit Design NonStandard Precast Concrete Unit Design ... ASTM C 143 Test Method for Slump of Hydraulic Cement ......

Cement Boards 101 Global Cement

Cement Boards 101. 19 December 2013 Picture 4: Fibre cement board (FCB). ... Typical cement board applications vary widely between the different board types due to the variable properties of each, but commonly include: Tile substrates, flooring and underlay, ... Bison plant production of CBPB....

Facility Layout | Cement | Mass Production Scribd

Process layout for a portion of Product layout for a portion of Cement plant Cement plant Cellular manufacturing (cm) layout • Grouping of machines into cells • Cells function somewhat like product layout within a larger shop or process layout • Each cell in ....

Modern Processing Techniques to minimize cost in .

Page 3 of 3 Grinding is a highly energy intensive process in the cement industry. Approximately 60 – 70 % of the total electrical ene rgy used in a cement plant is ....

Design a new cement plant Page 1 of 1

Design a new cement plant. I would like to ask you, experts some questions about designing a new cement plant. 1: We are going to invest a new cement plant and we are looking for the best place/location to construct the plant....

typical layout of mining plant typical layout plant supplier

plant layout of a cement plant icmcis2016. A successful redesign of the cement kiln could encompass modifications to fuel systems and plant layout with potential for other improvements in electricity. Chat Online typical cement plant layout . Get Price...

typical iron ore mines layout

Typical Coal Beneficiation Flowsheet Lajpatnagar Co InMobile Crushing Plant of a coal beneficiation plant a typical flow sheet of iron ore Typical Flow Sheet Of Iron Ore Beneficiation Prev :.basic crushing plant flow sheet Crushing Plant Design and Layout Considerations The image below is a schematic flow diagram of a typical oil refinery....

OYAK White Cement Worlds Leading Brand

Being the capacity and the market leader of the Turkish cement industry, OYAK Cimento continues its operations in 7 geographical regions through 7 integrated cement production plants....

RECOMMENDED PHYSICAL STANDARDS FOR MEAT AND .

Location of a plant and the sanitation of its outside premises can have a significant effect on the sanitation inside the plant. Meat, as it is handled in the plant, may become exposed to the outside elements through loading docks, doorways, open windows and the ....

(PDF) A Typical Manufacturing Plant Layout Design Using ...

A Typical Manufacturing Plant Layout Design Using CRAFT Algorithm Article (PDF Available) in Procedia Engineering 97 · December 2014 with 5,595 Reads DOI: /...

Lecture 4: Cement Production Flashcards | Quizlet

Limestone Quarries or deposits CALCIUM SOURCE CONTROLS LOCATION OF PLANT. Two basic Raw Materials in Cement. Calcareous Material and Argillaceous Material ... About what % of all CO2 emissions around the world is caused by cement production. 7%. How long does material stay in the kiln for the wet process? ... typical cement. accounts for 95% ......

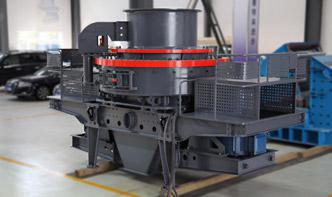

Supply Charcoal Making Machine and High performance ...

It is an ideal piece of crushing equipment for of technical reconstruction or setting up a new cement production lines for a cement plant. Also it is suitable for crushing iron ore, sandstone, gypsum, slag, gangue, lump coal and other hard special features: High and cubic crushing ratio....

Concrete Batch Plant Operator

Concrete Batch Plant Operator Study Guide Developed by the ... Application Production Mix Design Non Reinforced N/A N/A Reinforced lb/yd³ [ kg/m³] lb/yd³ ... Acceptance of the Portland cement at the batch plant will be based upon certified...

Manufacturing the cement kiln Understanding Cement

Most new cement plant is of this type. The principle is similar to that of the dry process preheater system but with the major addition of another burner, or precalciner. With the additional heat, about 85%95% of the meal is decarbonated before it enters the kiln. Basic principle of a precalciner cement kiln....