use of coal mill in cement manufacturing process

Fire and Explosion Hazards in Cement Manufacturing ...

Five fire hazards associated with the cement manufacturing process are outlined in the following sections. 1) Coal Storage. On average tonnes of coal are consumed in the kiln per kilogram of clinker cement production. As such coal storage during cement manufacturing is an important component to consider in hazard analysis....

Use of process analyzers in Cement cement plants Solutions ...

Use of process analyzers in cement plants Solutions from Siemens. Cement is a hydraulic binding agent to produce concrete. Due in part to the fast growth of the Asian econo mies, world consumption of cement is currently growing at an annual rate of 8%....

coal mill in cement manufacturing

coal mill in cement manufacturing process Manufacturing Process < About Cement < Cement: Lafarge . Lafarge is a leader in the use of alternative raw materials and fuels for fueling manufacturing coal, for fueling its cement Cement Manufacturing Process....

Why Opposition to New Cement Plants Using Coal as Fuel ...

The Real Impact of Using Natural Gas Instead of Coal to Fuel a Cement Kiln. The cement manufacturing process operates in a countercurrent flow, with the heat from the flame moving upward in one direction and the raw material (primarily ground limestone) moving downward in the other direction....

coal mill in cement process

coal mill process on cement plant. coal mill in cement manufacturing process 16 Feb 2014 process of coal mill in cement plant machinecement plant coal mill grinding flow sheet 12 sep 2012. Read More. 28 October. Cement making process Great Wall Corporation....

use of coal as cement kiln

Home > use of coal as cement kiln. ... The need to reduce emissions and reduce its fuel consumption provide the incentive for an Egyptian plant to change its manufacturing process. ... suppliers austint 7870 marble crusher machine diamond grinding magneticdiamond grinding manufacture milling apparatus flour cement mill notebook qatar cement ......

coal use in cement production process

production line concrete plant benefication plant feeder screen contact us...South Africa coal mill in cement manufacturing process South Africa coal mill... Free Chat Online coal use in cement production process...

coal milling for cement manufacturing

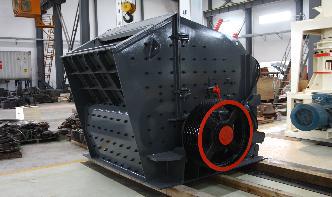

Coal Mill In Cement Manufacturing Process In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of raw material is limestone....

cement process coal mill

Clinker is the raw material used to manufacturing the cement. The clinker plant comprises of feed pre crusher, feed hopper, table feeders, ball mill, packaging cement plant and material handling equipment....

parts od a coal mill plant for cement manufacturing

coal mill in cement manufacturing – Grinding Mill China. coal mill in cement manufacturing processcoal processing plant. Coal Processing Plant,Coal Mill,Manufacturing,Beneficiation .. coal manufacturing process, coal mining machine operation,etc. Ball mill is widely used in. get price ; use of coal mill in cement manufacturing process...

Manufacturing process | Lafarge Cement, concrete ...

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km....

Cement making process Great Wall Corporation

cement process. (1). Most of the raw materials, like limestone, clay, iron ores, and coal, should be crushed before their prehomogenization. Limestone is the primary material in this line, and due to its large particle size and high hardness, it's good crushing plays an important role in the whole line....

Cement Process Energy Saving ECCJ

Sintering is formation of molten clinker by heating. Cooler: Molten clinker is quenched by cold air. (Suspension) preheater: Raw material (fine powder) is preheated in suspension state by hot gas coming from kiln. Precalciner: A part of calcining reaction is made in precalciner in modern NSP process....

coal mill in cement manufacturing

coal mill in cement manufacturing process coal mill in cement plants . coal mill in manufacturing process,16 Feb 2014 mill in sbm machine mill china, cement s .. select » Learn More....

steam coal cement process

steam coal cement process Coal mining is the process of extracting coal from the ground. Coal is valued for its energy content, and, since the 1880s, has been widely used to generate electricity. Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement production....

Cement manufacturing components of a cement plant

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the ' Clinker ' pages....

Cement kiln Wikipedia

A typical process of manufacture consists of three stages: grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill); heating the rawmix to sintering temperature (up to 1450 °C) in a cement kiln; grinding the resulting clinker to make cement (see Cement mill)....

on Life Cycle Assessment of Portland Cement Manufacturing ...

Cement Manufacturing Process. Overview of Life Cycle Assessment 11 Life Cycle of product, process, service. 12 Flow of presentation • Problem formation ... Cement mill Coal mill Human toxicit LM Crusher y potential (kg eq. 1,4 DCB) Evaluation of impact assessment. Sr. no. ....

Products_China Pengfei Group Co.,Ltd.

Mainly technological process of 1500t/d cement production line Mainly technological process of 2500t/d cement production line Mainly technological process of 3000t/d cement production line Mainly technological process of 5000t/d cement production line 100,000 Tons/Year Small Concrete Processing Plant 600 tons of active lime production line ......

coal grinder for cement manufacturing manufacturers

cement plant coal mill grinding flow sheet YouTube. Mar 29, 2017 . Random article use of coal mill in cement manufacturing process in india . grinding mill process flow sheet for cement manufacture. flow mill....

Manufacturing process | Lafarge Cement, concrete ...

Then, the mix is extracted transversely from the stockpile by reclaimers and conveyed to a raw mill bin called the raw mix bin for grinding. The other raw materials that are used in cement manufacturing, called additives, are high purity limestone, sand and iron ore....

What is dry process in cement manufacturing? Quora

Following is the procedure of manufacturing cement by dry process using modern technology: Boulders of limestone upto size are transported in huge dumpers upto 300kN capacity and dumped into the hopper of the crusher. The hammer mill crushers of single stage are now used for crushing....