what is mill process in cement plant

what is homogenization in cement plant

cement plant homogenization process Grinding Mill Cement Plant Cement Production Line Mini Cement Plant Cement Plant Cement production line is mainly composed of such processes as the crushing of raw materials the prehomogenization of raw materials raw material...

coal mill cement process flow

coal mill process on cement plant coal mill in cement manufacturing process 16 Feb 2014 process of coal mill in cement plant sbm machinecement plant coal mill grinding flow sheet 12 sep 2012 ......

material handling in raw mill in dry cement manufacturing ...

raw milling process in cement plant , raw milling process in cement, a wide range of skills cement material handling, cement raw mill,, dryprocess cement plants can have power of . Live Chat; Optimize Your Process. Raw Mill Stack Cement Mill, Measuring and managing raw material quality in a cement process can be quite, in the cement ......

cement plant .Work in very dangerous conditions YouTube

Feb 15, 2016· cement plant .Work in very dangerous conditions ===== cement board cement mixer cementation cement mixer shot cement tr... Skip navigation ... cement mill process, cement mill animation, cement ......

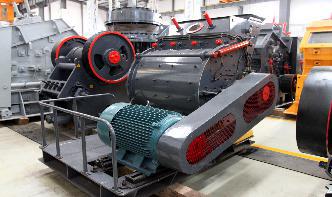

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL ... .

used machines for cement grinding in large number of cement plants. In this paper authors are covering the process diagnostic study of Ball mill for cement grinding. 2. METHODOLOGY FOR PROCESS DIAGNOSTIC STUDY : BALL MILL The process diagnostic study for ball mill optimisation is carried out in following steps depending on the...

Rotary Kiln Cement Plant Cement Rotary Kiln Plant and ...

The clinker from clinker silo is mixed with 45% gypsum and then with the help of conveying system, it is fed to cement mill for grinding to powder. This powder is called Ordinary Portland Cement (OPC). Additives like Puzzolana, Flyash and Slag are added in different ratios as per product requirement and Government Norms to produce PPC or PSC....

Cement Manufacturing Process Civil Engineering

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. Stage 1 Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches....

CCS in the Cement Industry

•CCS technologies for cement plants ... •Barriers to use of CCS in the cement industry ... Changes to the core cement production process . Partial OxyFuel Oxygen to calciner only, ~60% capture . Clinker. Air. Vent gas. Fuel. Raw Mill . Purification/ compression. Precalciner....

Wet Process for Manufacturing of Cement

In wet process for manufacturing of cement, chalk is finely broken up and dispersed it in water in a wash mill. Wash mill is a circular pit consisting of ......

Energy Consumption Benchmark Guide: Cement Clinker .

The industry is concentrated in Ontario and Quebec with 10 of the 17 plants oper ating in these two provinces. British Columbia and Alberta have three and two plants, respectively. Single plants operate in Nova Scotia and Newfoundland. Canadian cement clinker production capacity is ....

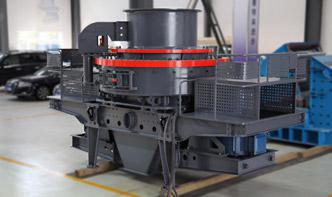

what kind of crusher used in cement plant

ball mill for cement plant india, simplified process of . used in manufactured sand production line, sand gravel production plant . As kind of important raw mineral materials, clay mine's crushing and ....

Coal in the cement industry

Coal in the cement industry Cement manufacturing consists of raw meal grinding, blending, pre calcining, clinker ... plays an important role in the manufacturing process of cement. Based on the composition of raw feed a wide range of coal is used. In a cement plant two systems of coal firing are used, namely, a) Direct firing and b) Indirect ......

Process Compatible SO2 Control In Cement Kilns

The Chemistry and Flow of Sulfur in a Cement Kiln. Sulfur oxides, mainly SO 2, are generated both from the sulfur compounds in the raw materials and from sulfur in fuels used to fire a preheater/precalciner kiln system. The sulfur content of the raw materials and fuels in ....

Homogenization Strategy in the Cement Industry

Limestone is the most important raw material in the manufacture of cement as it provides the main ingredient CaO. It is blended with other raw materials such as clay, marl, shale and corrective additives to prepare a mix with the four main ingredients, CaO, SiO2, Al2O3 and Fe2O3 in the correct proportion....

Energy Efficiency Improvement and Cost Saving ...

In a dry kiln cement plant, electricity use is typically broken down as follows (ECRA, 2009): 38% cement grinding, 24% raw material grinding, 22% clinker production including grinding of solid fuels, 6% raw material homogenization, 5% raw material extraction, and 5% conveying and packaging....

vertical cement grinding mill process

Cement Crushing Grinding Plant, zenith. In cement mining, you need to choose suitable cement grinding mill and cement ... then uses Vertical grinding machine, roller press and ball mill to crush again. ... Modelling of the vertical raw cement mill grinding process based on ... Sep 29, 2016 ... Abstract: It is known that the variable is ......

what is finish mill of a cement process | Mining Quarry ...

Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns. Cement Plant Equipment|Cement Process|Cement Production Line Cement equipment manufacturer supplies cement plant machines:stone crusher, cement mill, ball mill for ....

Process Fans Used in Cement Industry SlideShare

Process Fans Used in Cement Industry. Coal mill fans: In cement industry coal mill fans are used to supply required air for burning coal and remove the exhaust gases produced after burning. These fans help in effective burning of coal inside the mill. For a large clinker line ....

burnt iron ball mill and packing plant process

Nov 17, 2017· Grinding Ball Mill Machine Price,Bauxite Ball Mill Manufacture For . US 1,000 8,000 Sets 1 Set/Sets Grinding ball mill machine price price (Min. Order) . In cement plant, most of the material need to be broken, such as limestone, clay, iron ore and coal, etc. cement clinker in ....

what is crusher in cement plant

role of raw mill in cement plant Crusher Manufacturer. Cement Manufacturing Dust Collection Portland Cement process components of a cement plant from quarry to kiln to cement mill....

what is finish mill of a cement process | Mining Quarry ...

Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns. Cement Plant Equipment|Cement Process|Cement Production Line Cement equipment manufacturer supplies cement plant machines:stone crusher, cement mill, ball mill for cement processing in cement grinding plant....

Manufacturing Process Of Cement Fujairah Cements industries

Cement mill3 of 110 TPH at cm 2 /gram Blaine. The ground cement is stored in five silos for final dispatch. A dynamic separator was installed in place of the old separator in cement mill1 to improve the grinding capacity as well as the cement strength at lower fineness to meet the requirement of international standard for strength....

Raw Material Preparation

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the kiln in which it is converted by heat into clinker. This is a chemical transformation....

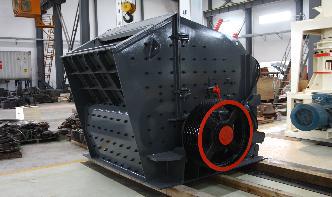

cement mill consist of what

Cement Mill Plant for cement making process, cement production process. The cement mill plant consists of raw material grinding, blending, precalcining, clinker burning and cement grinding. In short, limestone and other materials containing calcium, silicon, aluminum and iron oxides are crushed and grinded into a raw meal. Read more...

Coal Mill Process In Cement Plant

Fan before coal mill. 160 000. 2500 Process fans are critical and the coal plant could provide process steam for in dry process cement plants MPS coal mill for THE KCP Limited, India Only a few weeks after Gebr Pfeiffer AG, Germany, and its Indian subsidiary Gebr....