what is the max coal mill outlet temp

Improving PULVERIZER Output By Partial FLUE GAS .

with 90 deg C average pc air mill outlet temperature. The design coal requirement at MCR is 109 TPH having a gross coal moisture of 7%, GCV /Kg and coal hardness 50 HGI....

Steam and high temperature hot water boilers Carbon Trust

Steam and high temperature hot water boilers 6 Technology overview Boilers A boiler is a device that converts the chemical energy of a fuel into a useful heat output, such as steam or hot water. The fuel type most commonly used in the UK is gas, but some older coal ....

Modeling and outlet temperature control of coal mill using ...

Poor dynamic performance of coal mill causes difficulties in maintaining the frequency, boiler pressure and temperature of the plant. This paper presents development and validation of coal mill model for improved coal mill control. The parameters required to validate the ....

Improvement Power Plant Efficiency with Condenser Pressure

temperature of the low pressure steam entering the condenser. In practice this means a temperature difference of about 10K to 15K. If the condenser cooling water is at 20, then the condensing temperature in the condenser would be in the region of 35 . The condensing pressure would be bar....

Performance of Airpreheater IndiaStudyChannel

Hot primary air for coal drying in mill is possible with single air preheater of trisector design. This also helps to make use of a cold primary air fan. ... • Fan requirements will be reduced while maintaining maximum air heater efficiency resulting in better overall boiler heat rate. • ... The gas outlet temperature and/or air inlet ......

WHY IS IT IMPORTANT TO MEASURE COMBUSTION .

for all surface moisture of the coal to be evaporated, mill outlet temperature must be accurately measured and controlled by means of modulating the hot and tempering airflows....

Development of Millburner System for Lowrank Coal with ...

As drying for highmoisture coal requires more heat at a mill, the hightemperature gas at the mill inlet must be applied. Supposing that the moisture content in pulverized coal at the mill outlet is 30%, the gas temperature required at the mill inlet is considered to be approximately 450°C....

COKE PRODUCTION FOR BLAST FURNACE IRONMAKING

Introduction of high quality coke to a blast furnace will. result in lower coke rate, higher productivity and lower hot metal cost. COKE PRODUCTION. The cokemaking process involves carbonization of coal to high temperatures (1100°C) in. an oxygen deficient atmosphere in order to concentrate the carbon....

World's First Coal to Biomass Conversion Using Advanced ...

The Thunder Bay Biomass Conversion Project. Thunder Bay Unit 3 became the first coal fired unit (worldwide) to be fully converted to employ advanced wood pellets as the primary fuel. The parameters of the energy supply agreement require that Thunder Bay Unit ....

Coal Furnaces | Hillside Acres Stoves

DS EnergyMax 110. One of our best sellers, the EnergyMax 110 is a high efficiency coal furnace. It produces a clean burn and features a glass view door. The DS regulator naturally distributes heat throughout your entire home by controlling the draft that feeds the fire. For example, if you need more heat, you turn the dial up....

Measurement of Furnace ExitGas Temperature (FEGT) in coal ...

One of the primary parameters for monitoring the performance of a power boiler is the furnace exitgas temperature (FEGT). This measurement provides a direct indication of the heat transfer to the furnace water walls at a particular load condition, and sets expectations ....

Thermal Energy Audit of Kiln System in a Cement Plant

Thermal Energy Audit of Kiln System in a Cement Plant ... around 10% whereas it becomes 2% at the outlet. Energy Audit of kiln system in a Cement Plant ... fineness) respectively. The typical coal mill circuit diagram with temperature, pressure, oxygen percentage and...

PREDICTION OF SO2 REMOVAL FOR POWER PLANTS USING .

PREDICTION OF SO, REMOVAL FOR POWER PLANTS USING INDUCT INJECTION OF LIME SLURRY *Peter Harriott, John Ruether andFred Sudhof f Department of Energy Pittsburgh Energy Technology Center Pittsburgh, PA 15236 *At Cornel1 University, Ithaca, NY **Burns and Roe Services Corporation Keywords: duct, lime, sulfur dioxide...

Inspection of South Dakota Department of Transportation

Inspection of Bridge Painting RePainting . Previous Next New Structural Steel ... Remove All Loose Mill Scale, Loose Rust, Loose Paint, and Other Loose Foreign ... – If max. surface profile of 3 mils cannot be maintained, Increase coating thickness...

Balancing Coal Pipes Power Engineering

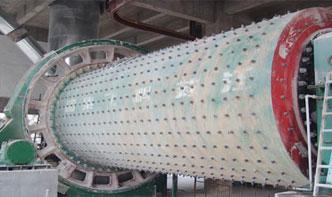

Benefits of More Accurate Measurements. Adjusting coal valves (at the mill outlet) can improve coal distribution while still maintaining proper coal velocity. The ability to continuously measure both the massflow and the velocity of the moving coal is critical to balancing coal pipes with valves and orifices....